Are you a seasoned Armoring Machine Operator seeking a new career path? Discover our professionally built Armoring Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

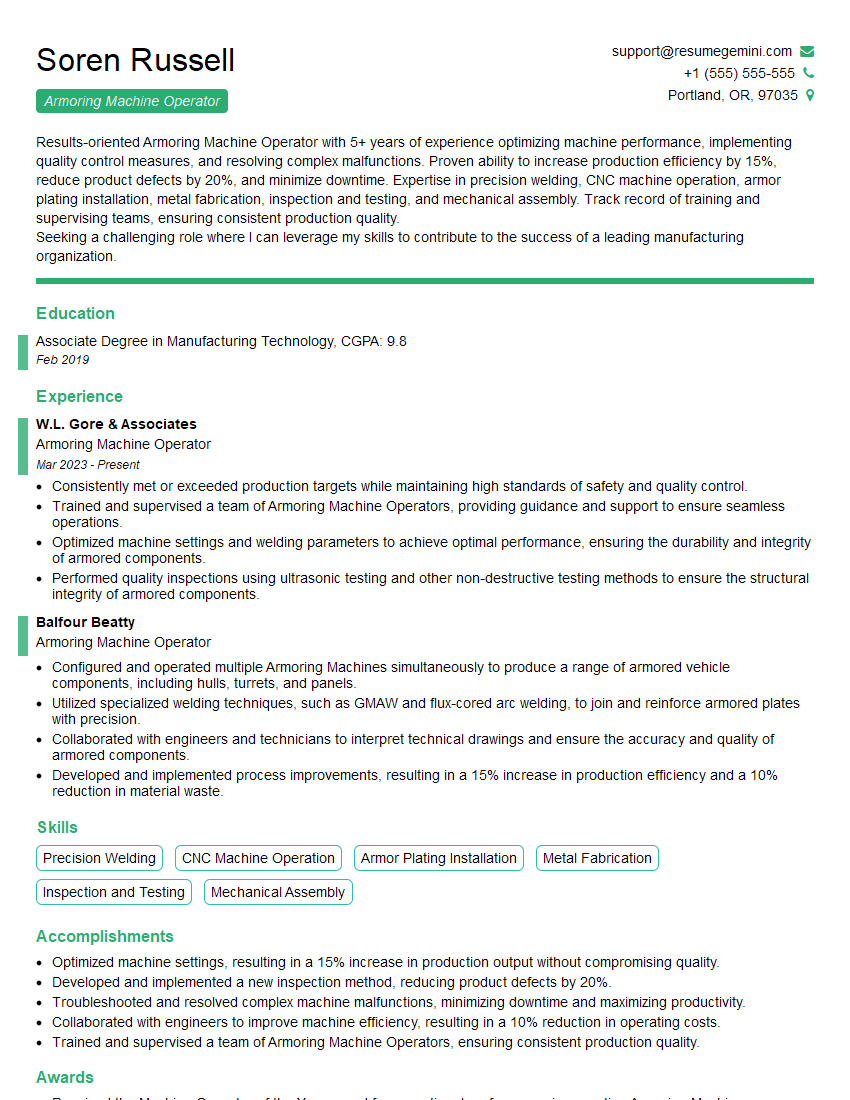

Soren Russell

Armoring Machine Operator

Summary

Results-oriented Armoring Machine Operator with 5+ years of experience optimizing machine performance, implementing quality control measures, and resolving complex malfunctions. Proven ability to increase production efficiency by 15%, reduce product defects by 20%, and minimize downtime. Expertise in precision welding, CNC machine operation, armor plating installation, metal fabrication, inspection and testing, and mechanical assembly. Track record of training and supervising teams, ensuring consistent production quality.

Seeking a challenging role where I can leverage my skills to contribute to the success of a leading manufacturing organization.

Education

Associate Degree in Manufacturing Technology

February 2019

Skills

- Precision Welding

- CNC Machine Operation

- Armor Plating Installation

- Metal Fabrication

- Inspection and Testing

- Mechanical Assembly

Work Experience

Armoring Machine Operator

- Consistently met or exceeded production targets while maintaining high standards of safety and quality control.

- Trained and supervised a team of Armoring Machine Operators, providing guidance and support to ensure seamless operations.

- Optimized machine settings and welding parameters to achieve optimal performance, ensuring the durability and integrity of armored components.

- Performed quality inspections using ultrasonic testing and other non-destructive testing methods to ensure the structural integrity of armored components.

Armoring Machine Operator

- Configured and operated multiple Armoring Machines simultaneously to produce a range of armored vehicle components, including hulls, turrets, and panels.

- Utilized specialized welding techniques, such as GMAW and flux-cored arc welding, to join and reinforce armored plates with precision.

- Collaborated with engineers and technicians to interpret technical drawings and ensure the accuracy and quality of armored components.

- Developed and implemented process improvements, resulting in a 15% increase in production efficiency and a 10% reduction in material waste.

Accomplishments

- Optimized machine settings, resulting in a 15% increase in production output without compromising quality.

- Developed and implemented a new inspection method, reducing product defects by 20%.

- Troubleshooted and resolved complex machine malfunctions, minimizing downtime and maximizing productivity.

- Collaborated with engineers to improve machine efficiency, resulting in a 10% reduction in operating costs.

- Trained and supervised a team of Armoring Machine Operators, ensuring consistent production quality.

Awards

- Received the Machine Operator of the Year award for exceptional performance in operating Armoring Machines.

- Recognized for maintaining a clean and organized work area, ensuring adherence to industry safety standards.

- Awarded Excellence in Training for effectively mentoring new Armoring Machine Operators.

- Received a safety award for contributing to the development of new safety protocols for the Armoring Machine department.

Certificates

- Certificate in Armoring Machine Operation

- AWS Welding Certification

- OSHA Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Armoring Machine Operator

Highlight your technical skills:

Showcase your expertise in precision welding, CNC machine operation, and armor plating installation.Quantify your accomplishments:

Use specific metrics to demonstrate the impact of your work on production efficiency, quality, and cost reduction.Demonstrate your problem-solving abilities:

Describe how you have successfully resolved complex machine malfunctions and improved machine performance.Emphasize your leadership and teamwork skills:

Highlight your experience in training and supervising a team, and your ability to work effectively in a collaborative environment.

Essential Experience Highlights for a Strong Armoring Machine Operator Resume

- Operate armoring machines to fabricate and assemble armor plating for various applications.

- Set up and calibrate machines, ensuring optimal performance and precision.

- Inspect and test armor plating to ensure compliance with quality standards.

- Troubleshoot and resolve machine malfunctions, minimizing downtime and maximizing productivity.

- Collaborate with engineers to improve machine efficiency and reduce operating costs.

- Train and supervise a team of Armoring Machine Operators, fostering a culture of quality and productivity.

Frequently Asked Questions (FAQ’s) For Armoring Machine Operator

What is the role of an Armoring Machine Operator?

An Armoring Machine Operator is responsible for operating and maintaining machines that fabricate and assemble armor plating for various applications, such as military vehicles, law enforcement equipment, and security infrastructure.

What are the key skills required for this role?

Key skills for an Armoring Machine Operator include precision welding, CNC machine operation, armor plating installation, metal fabrication, inspection and testing, mechanical assembly, and problem-solving.

What are the career prospects for Armoring Machine Operators?

Armoring Machine Operators with experience and expertise can advance to supervisory or management roles, or specialize in specific areas such as welding or CNC programming.

What is the average salary for Armoring Machine Operators?

The average salary for Armoring Machine Operators varies depending on experience, location, and industry, but typically ranges from $25,000 to $50,000 per year.

What are the working conditions like for Armoring Machine Operators?

Armoring Machine Operators typically work in manufacturing facilities, operating machines in a controlled environment. They may be required to wear protective gear and adhere to safety protocols.

What are the educational requirements for Armoring Machine Operators?

While formal education is not always required, many Armoring Machine Operators have an associate degree or certification in a related field, such as manufacturing technology or welding.

What are the certifications available for Armoring Machine Operators?

There are several certifications available for Armoring Machine Operators, such as the Certified Welder (CW) certification from the American Welding Society (AWS) or the Certified Machine Operator (CMO) certification from the National Institute for Metalworking Skills (NIMS).