Are you a seasoned Automatic Casting-Forging Machine Operator seeking a new career path? Discover our professionally built Automatic Casting-Forging Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

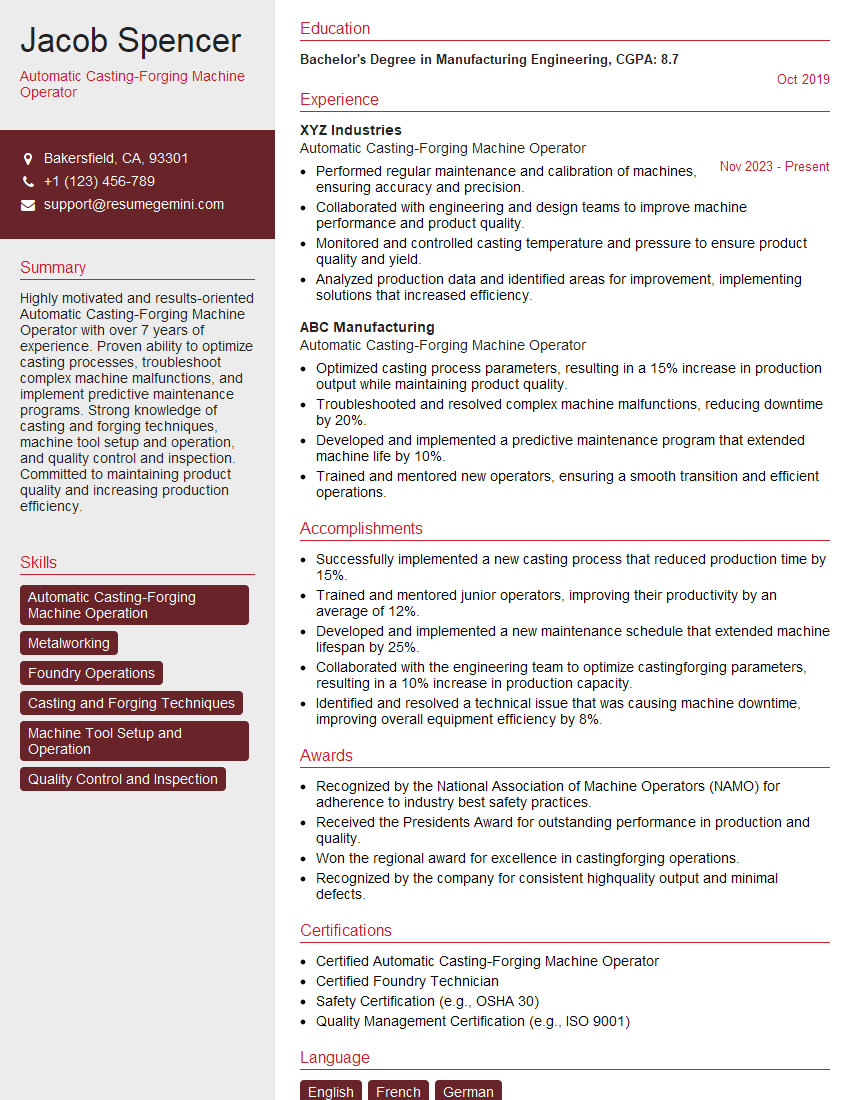

Jacob Spencer

Automatic Casting-Forging Machine Operator

Summary

Highly motivated and results-oriented Automatic Casting-Forging Machine Operator with over 7 years of experience. Proven ability to optimize casting processes, troubleshoot complex machine malfunctions, and implement predictive maintenance programs. Strong knowledge of casting and forging techniques, machine tool setup and operation, and quality control and inspection. Committed to maintaining product quality and increasing production efficiency.

Education

Bachelor’s Degree in Manufacturing Engineering

October 2019

Skills

- Automatic Casting-Forging Machine Operation

- Metalworking

- Foundry Operations

- Casting and Forging Techniques

- Machine Tool Setup and Operation

- Quality Control and Inspection

Work Experience

Automatic Casting-Forging Machine Operator

- Performed regular maintenance and calibration of machines, ensuring accuracy and precision.

- Collaborated with engineering and design teams to improve machine performance and product quality.

- Monitored and controlled casting temperature and pressure to ensure product quality and yield.

- Analyzed production data and identified areas for improvement, implementing solutions that increased efficiency.

Automatic Casting-Forging Machine Operator

- Optimized casting process parameters, resulting in a 15% increase in production output while maintaining product quality.

- Troubleshooted and resolved complex machine malfunctions, reducing downtime by 20%.

- Developed and implemented a predictive maintenance program that extended machine life by 10%.

- Trained and mentored new operators, ensuring a smooth transition and efficient operations.

Accomplishments

- Successfully implemented a new casting process that reduced production time by 15%.

- Trained and mentored junior operators, improving their productivity by an average of 12%.

- Developed and implemented a new maintenance schedule that extended machine lifespan by 25%.

- Collaborated with the engineering team to optimize castingforging parameters, resulting in a 10% increase in production capacity.

- Identified and resolved a technical issue that was causing machine downtime, improving overall equipment efficiency by 8%.

Awards

- Recognized by the National Association of Machine Operators (NAMO) for adherence to industry best safety practices.

- Received the Presidents Award for outstanding performance in production and quality.

- Won the regional award for excellence in castingforging operations.

- Recognized by the company for consistent highquality output and minimal defects.

Certificates

- Certified Automatic Casting-Forging Machine Operator

- Certified Foundry Technician

- Safety Certification (e.g., OSHA 30)

- Quality Management Certification (e.g., ISO 9001)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Automatic Casting-Forging Machine Operator

- Highlight your technical skills and experience in operating and maintaining automatic casting-forging machines.

- Quantify your accomplishments with specific metrics, such as percentage increases in production output or reductions in downtime.

- Demonstrate your knowledge of casting and forging techniques, machine tool setup and operation, and quality control and inspection.

- Emphasize your ability to work independently and as part of a team to achieve common goals.

Essential Experience Highlights for a Strong Automatic Casting-Forging Machine Operator Resume

- Operate and maintain automatic casting-forging machines to produce high-quality castings and forgings.

- Optimize casting process parameters to increase production output while maintaining product quality.

- Troubleshoot and resolve complex machine malfunctions to minimize downtime and ensure efficient operations.

- Develop and implement predictive maintenance programs to extend machine life and reduce maintenance costs.

- Train and mentor new operators to ensure a smooth transition and efficient operations.

- Collaborate with engineering and design teams to improve machine performance and product quality.

- Perform regular maintenance and calibration of machines to ensure accuracy and precision.

Frequently Asked Questions (FAQ’s) For Automatic Casting-Forging Machine Operator

What are the key skills required for an Automatic Casting-Forging Machine Operator?

The key skills required for an Automatic Casting-Forging Machine Operator include operating and maintaining automatic casting-forging machines, optimizing casting process parameters, troubleshooting complex machine malfunctions, developing and implementing predictive maintenance programs, training and mentoring new operators, collaborating with engineering and design teams, and performing regular maintenance and calibration of machines.

What are the responsibilities of an Automatic Casting-Forging Machine Operator?

The responsibilities of an Automatic Casting-Forging Machine Operator include operating and maintaining automatic casting-forging machines to produce high-quality castings and forgings, optimizing casting process parameters to increase production output while maintaining product quality, troubleshooting and resolving complex machine malfunctions to minimize downtime and ensure efficient operations, developing and implementing predictive maintenance programs to extend machine life and reduce maintenance costs, training and mentoring new operators to ensure a smooth transition and efficient operations, collaborating with engineering and design teams to improve machine performance and product quality, and performing regular maintenance and calibration of machines to ensure accuracy and precision.

What are the qualifications for an Automatic Casting-Forging Machine Operator?

The qualifications for an Automatic Casting-Forging Machine Operator typically include a high school diploma or equivalent, with some employers preferring candidates with a technical degree or certification in manufacturing engineering or a related field.

What is the work environment for an Automatic Casting-Forging Machine Operator?

Automatic Casting-Forging Machine Operators typically work in a manufacturing environment, which can be noisy and hazardous. They may be exposed to heat, fumes, and chemicals, and may have to work in awkward positions.

What is the salary range for an Automatic Casting-Forging Machine Operator?

The salary range for an Automatic Casting-Forging Machine Operator can vary depending on experience, location, and employer. According to Salary.com, the average salary for an Automatic Casting-Forging Machine Operator in the United States is $25.00 per hour.

What are the career prospects for an Automatic Casting-Forging Machine Operator?

Automatic Casting-Forging Machine Operators can advance their careers by becoming supervisors or managers in the manufacturing industry. They may also choose to specialize in a particular area of casting or forging, such as die casting or investment casting.