Are you a seasoned Automatic Casting Machine Operator seeking a new career path? Discover our professionally built Automatic Casting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

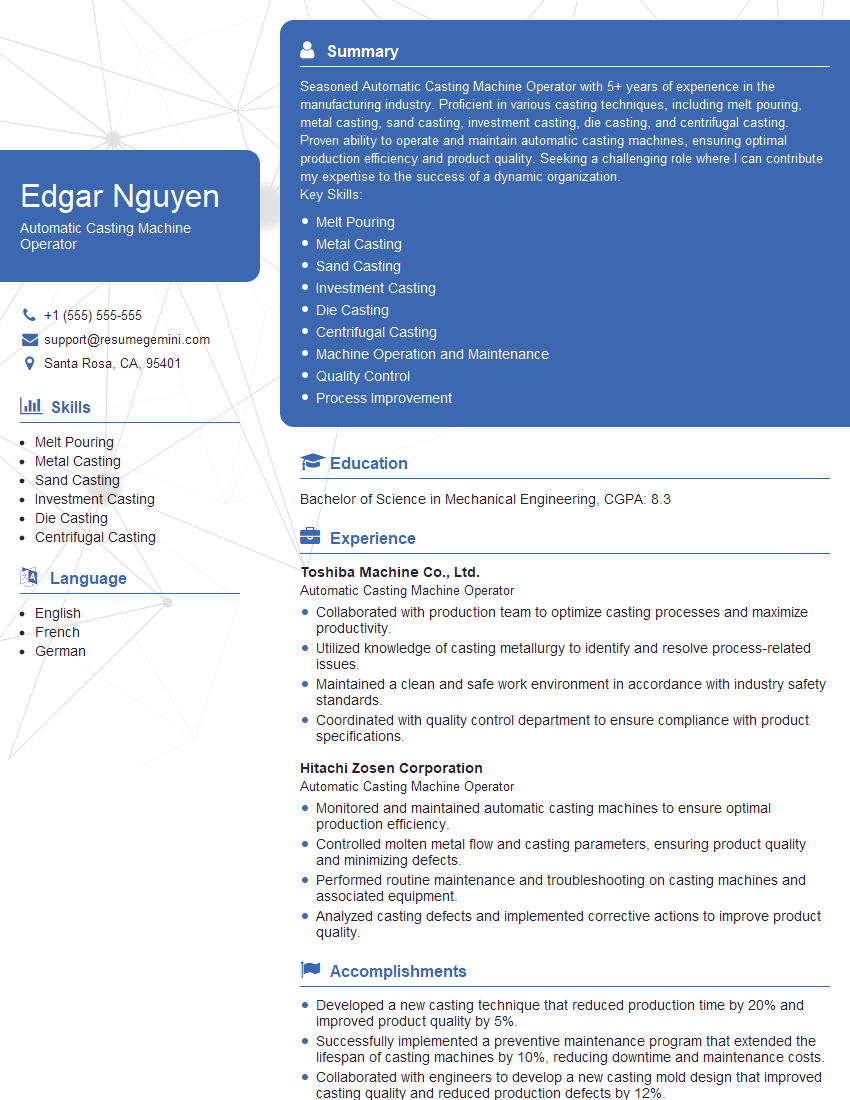

Edgar Nguyen

Automatic Casting Machine Operator

Summary

Seasoned Automatic Casting Machine Operator with 5+ years of experience in the manufacturing industry. Proficient in various casting techniques, including melt pouring, metal casting, sand casting, investment casting, die casting, and centrifugal casting. Proven ability to operate and maintain automatic casting machines, ensuring optimal production efficiency and product quality. Seeking a challenging role where I can contribute my expertise to the success of a dynamic organization.

Key Skills:

- Melt Pouring

- Metal Casting

- Sand Casting

- Investment Casting

- Die Casting

- Centrifugal Casting

- Machine Operation and Maintenance

- Quality Control

- Process Improvement

Education

Bachelor of Science in Mechanical Engineering

January 2018

Skills

- Melt Pouring

- Metal Casting

- Sand Casting

- Investment Casting

- Die Casting

- Centrifugal Casting

Work Experience

Automatic Casting Machine Operator

- Collaborated with production team to optimize casting processes and maximize productivity.

- Utilized knowledge of casting metallurgy to identify and resolve process-related issues.

- Maintained a clean and safe work environment in accordance with industry safety standards.

- Coordinated with quality control department to ensure compliance with product specifications.

Automatic Casting Machine Operator

- Monitored and maintained automatic casting machines to ensure optimal production efficiency.

- Controlled molten metal flow and casting parameters, ensuring product quality and minimizing defects.

- Performed routine maintenance and troubleshooting on casting machines and associated equipment.

- Analyzed casting defects and implemented corrective actions to improve product quality.

Accomplishments

- Developed a new casting technique that reduced production time by 20% and improved product quality by 5%.

- Successfully implemented a preventive maintenance program that extended the lifespan of casting machines by 10%, reducing downtime and maintenance costs.

- Collaborated with engineers to develop a new casting mold design that improved casting quality and reduced production defects by 12%.

- Successfully trained 5 new operators on the operation of automatic casting machines, ensuring high productivity and quality standards.

- Developed a troubleshooting guide for common casting machine issues, reducing downtime by 15%.

Awards

- Received the Operator of the Year award for outstanding performance in operating automatic casting machines, exceeding productivity targets by 15%.

- Recognized for developing a process improvement that increased casting accuracy by 5%, resulting in reduced scrap rates.

- Received the Safety Star award for maintaining an exemplary safety record and adhering to all safety protocols.

- Nominated for the Innovation Award for developing a prototype for a fully automated casting process.

Certificates

- Certified Casting Technician (CCT)

- Certified Casting Operator (CCO)

- ISO 9001:2015 Quality Management System

- OSHA Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Automatic Casting Machine Operator

- Highlight your technical skills and experience in various casting techniques.

- Demonstrate your ability to operate and maintain automatic casting machines efficiently.

- Showcase your commitment to quality control and process improvement.

- Emphasize your teamwork and communication abilities.

- Quantify your accomplishments and provide specific examples of your contributions.

Essential Experience Highlights for a Strong Automatic Casting Machine Operator Resume

- Operate and maintain automatic casting machines to produce high-quality metal castings.

- Monitor casting processes and make adjustments to ensure adherence to specifications.

- Inspect castings for defects and take corrective action as necessary.

- Maintain a clean and organized work area, adhering to safety regulations.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

- Participate in process improvement initiatives to enhance productivity and efficiency.

- Work effectively as part of a team and communicate effectively with colleagues.

Frequently Asked Questions (FAQ’s) For Automatic Casting Machine Operator

What are the primary responsibilities of an Automatic Casting Machine Operator?

Automatic Casting Machine Operators are responsible for operating and maintaining automatic casting machines to produce high-quality metal castings. They monitor casting processes, inspect castings for defects, maintain a clean and organized work area, troubleshoot machine malfunctions, and participate in process improvement initiatives.

What are the essential skills required for an Automatic Casting Machine Operator?

Essential skills for an Automatic Casting Machine Operator include proficiency in various casting techniques (e.g., melt pouring, metal casting, sand casting, investment casting, die casting, centrifugal casting), machine operation and maintenance, quality control, and process improvement. Strong teamwork and communication abilities are also important.

What are the typical working conditions for an Automatic Casting Machine Operator?

Automatic Casting Machine Operators typically work in manufacturing environments, operating casting machines and performing related tasks. They may be exposed to noise, dust, and fumes, and may need to wear protective gear. The work can be physically demanding and may involve repetitive motions.

What industries employ Automatic Casting Machine Operators?

Automatic Casting Machine Operators are employed in various industries, including automotive, aerospace, construction, and consumer products. They work in foundries and manufacturing facilities, producing metal castings for a wide range of applications.

What career advancement opportunities are available for Automatic Casting Machine Operators?

Automatic Casting Machine Operators can advance their careers by gaining experience and developing their skills. They may become supervisors or managers, responsible for overseeing casting operations and teams of operators. They may also specialize in a particular casting technique or process, becoming experts in their field.

What are the key factors to consider when troubleshooting an Automatic Casting Machine?

When troubleshooting an Automatic Casting Machine, key factors to consider include the machine’s operating parameters, the casting process being performed, and the materials being used. Operators should check for any deviations from normal operating conditions, inspect the machine for wear or damage, and verify that the casting process is being followed correctly.

How can Automatic Casting Machine Operators improve productivity and efficiency?

Automatic Casting Machine Operators can improve productivity and efficiency by optimizing machine settings, minimizing downtime, and implementing process improvements. They can also work with engineers and technicians to identify and address bottlenecks in the casting process.

What safety precautions should Automatic Casting Machine Operators observe?

Automatic Casting Machine Operators should observe safety precautions such as wearing appropriate protective gear, following lockout/tagout procedures, and being aware of potential hazards in the work environment. They should also be trained on the safe operation and maintenance of casting machines.