Are you a seasoned Automatic Outsole Cutter seeking a new career path? Discover our professionally built Automatic Outsole Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

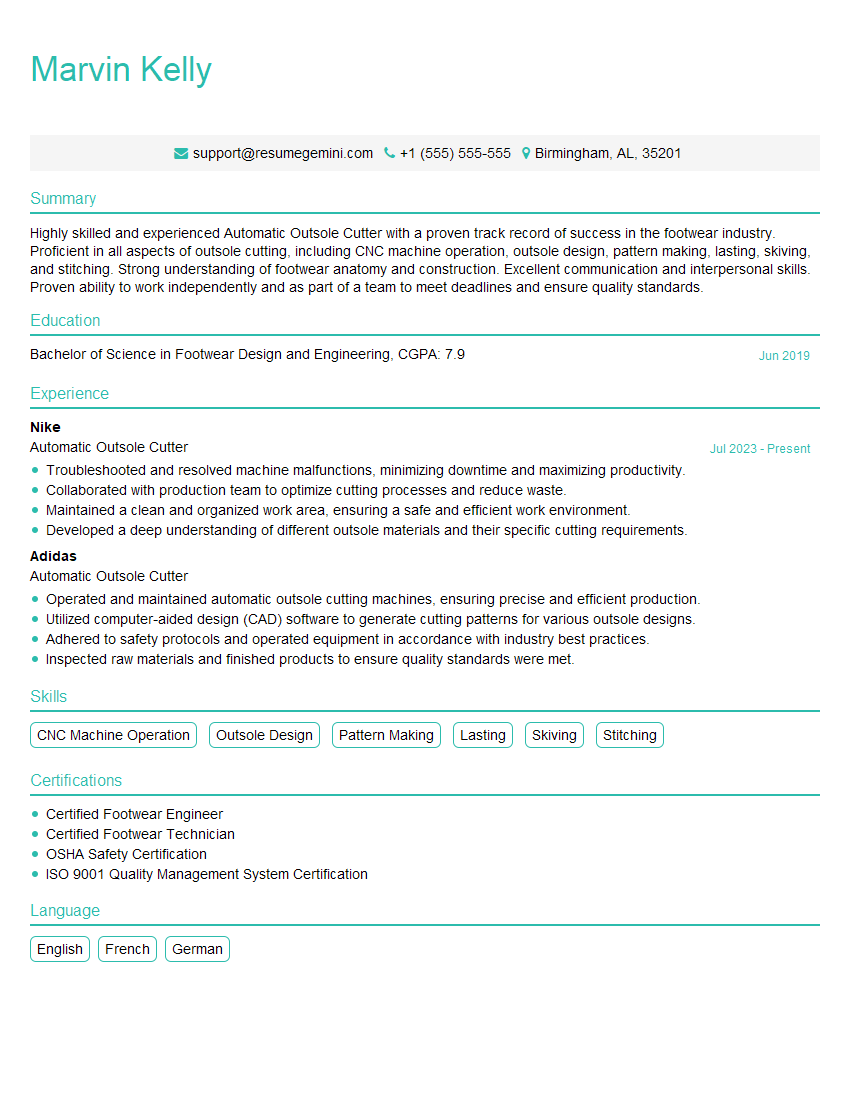

Marvin Kelly

Automatic Outsole Cutter

Summary

Highly skilled and experienced Automatic Outsole Cutter with a proven track record of success in the footwear industry. Proficient in all aspects of outsole cutting, including CNC machine operation, outsole design, pattern making, lasting, skiving, and stitching. Strong understanding of footwear anatomy and construction. Excellent communication and interpersonal skills. Proven ability to work independently and as part of a team to meet deadlines and ensure quality standards.

Education

Bachelor of Science in Footwear Design and Engineering

June 2019

Skills

- CNC Machine Operation

- Outsole Design

- Pattern Making

- Lasting

- Skiving

- Stitching

Work Experience

Automatic Outsole Cutter

- Troubleshooted and resolved machine malfunctions, minimizing downtime and maximizing productivity.

- Collaborated with production team to optimize cutting processes and reduce waste.

- Maintained a clean and organized work area, ensuring a safe and efficient work environment.

- Developed a deep understanding of different outsole materials and their specific cutting requirements.

Automatic Outsole Cutter

- Operated and maintained automatic outsole cutting machines, ensuring precise and efficient production.

- Utilized computer-aided design (CAD) software to generate cutting patterns for various outsole designs.

- Adhered to safety protocols and operated equipment in accordance with industry best practices.

- Inspected raw materials and finished products to ensure quality standards were met.

Certificates

- Certified Footwear Engineer

- Certified Footwear Technician

- OSHA Safety Certification

- ISO 9001 Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Automatic Outsole Cutter

- Highlight your experience and skills in all aspects of outsole cutting.

- Showcase your knowledge of footwear anatomy and construction.

- Demonstrate your proficiency in using CNC outsole cutting machines.

- Emphasize your ability to work independently and as part of a team.

- Include relevant keywords throughout your resume.

Essential Experience Highlights for a Strong Automatic Outsole Cutter Resume

- Operate CNC outsole cutting machines to cut outsoles for footwear.

- Design and create outsoles using computer-aided design (CAD) software.

- Develop and modify patterns for outsoles using a variety of materials.

- Last and stitch outsoles to uppers to create complete footwear.

- Skive outsoles to prepare them for lasting and stitching.

- Inspect outsoles for quality and ensure they meet specifications.

- Maintain and calibrate CNC outsole cutting machines.

Frequently Asked Questions (FAQ’s) For Automatic Outsole Cutter

What is an Automatic Outsole Cutter?

An Automatic Outsole Cutter is a machine that is used to cut the outsoles of shoes. It is a computer-controlled machine that uses a variety of cutting tools to cut the outsoles to the desired shape and size.

What are the benefits of using an Automatic Outsole Cutter?

There are many benefits to using an Automatic Outsole Cutter, including: Increased accuracy and precision: Automatic Outsole Cutters are able to cut outsoles with a high degree of accuracy and precision, which can help to improve the overall quality of the shoes. Increased efficiency: Automatic Outsole Cutters can cut outsoles much faster than manual methods, which can help to improve productivity and reduce costs. Reduced waste: Automatic Outsole Cutters can help to reduce waste by cutting outsoles to the exact size and shape needed, which can help to save money on materials.

What are the different types of Automatic Outsole Cutters?

There are two main types of Automatic Outsole Cutters: CNC Outsole Cutters: CNC Outsole Cutters are computer-controlled machines that use a variety of cutting tools to cut outsoles to the desired shape and size. Laser Outsole Cutters: Laser Outsole Cutters use a laser to cut outsoles to the desired shape and size.

What are the factors to consider when choosing an Automatic Outsole Cutter?

There are a number of factors to consider when choosing an Automatic Outsole Cutter, including: The type of outsoles that will be cut: The type of outsoles that will be cut will determine the type of Automatic Outsole Cutter that is needed. The volume of outsoles that will be cut: The volume of outsoles that will be cut will determine the size and capacity of the Automatic Outsole Cutter that is needed. The budget: The budget will determine the type and features of the Automatic Outsole Cutter that can be purchased.

How to maintain an Automatic Outsole Cutter?

To maintain an Automatic Outsole Cutter, it is important to: Keep the machine clean: The machine should be cleaned regularly to remove any dirt or debris that may accumulate. Lubricate the machine: The machine should be lubricated regularly to ensure that all moving parts are functioning properly. Calibrate the machine: The machine should be calibrated regularly to ensure that it is cutting outsoles to the correct size and shape. Inspect the machine: The machine should be inspected regularly for any signs of wear or damage.

What are the safety precautions that should be taken when using an Automatic Outsole Cutter?

When using an Automatic Outsole Cutter, it is important to take the following safety precautions: Wear appropriate safety gear: When using an Automatic Outsole Cutter, it is important to wear appropriate safety gear, such as safety glasses, gloves, and a dust mask. Keep hands away from the cutting area: When the machine is in operation, it is important to keep hands away from the cutting area to avoid injury. Be aware of the surroundings: When using an Automatic Outsole Cutter, it is important to be aware of the surroundings and to avoid tripping or bumping into anything.