Are you a seasoned Automatic Pattern Edger seeking a new career path? Discover our professionally built Automatic Pattern Edger Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

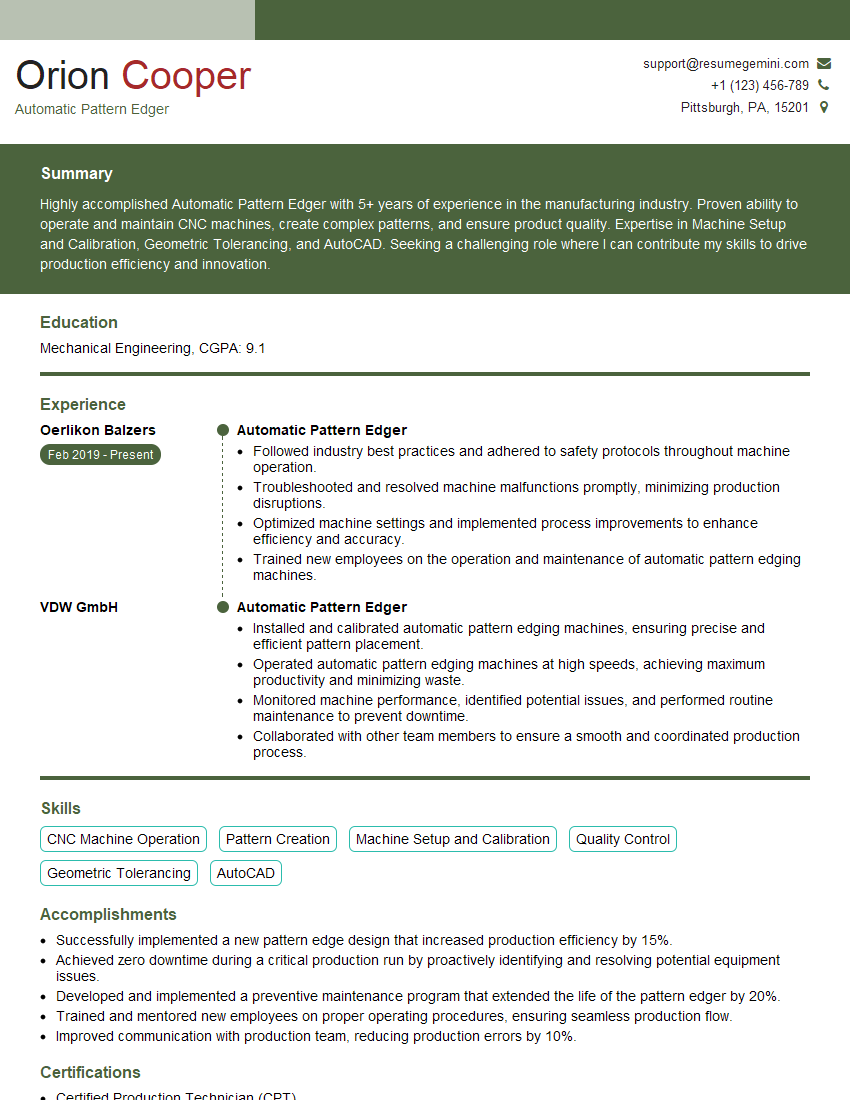

Orion Cooper

Automatic Pattern Edger

Summary

Highly accomplished Automatic Pattern Edger with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain CNC machines, create complex patterns, and ensure product quality. Expertise in Machine Setup and Calibration, Geometric Tolerancing, and AutoCAD. Seeking a challenging role where I can contribute my skills to drive production efficiency and innovation.

Education

Mechanical Engineering

January 2015

Skills

- CNC Machine Operation

- Pattern Creation

- Machine Setup and Calibration

- Quality Control

- Geometric Tolerancing

- AutoCAD

Work Experience

Automatic Pattern Edger

- Followed industry best practices and adhered to safety protocols throughout machine operation.

- Troubleshooted and resolved machine malfunctions promptly, minimizing production disruptions.

- Optimized machine settings and implemented process improvements to enhance efficiency and accuracy.

- Trained new employees on the operation and maintenance of automatic pattern edging machines.

Automatic Pattern Edger

- Installed and calibrated automatic pattern edging machines, ensuring precise and efficient pattern placement.

- Operated automatic pattern edging machines at high speeds, achieving maximum productivity and minimizing waste.

- Monitored machine performance, identified potential issues, and performed routine maintenance to prevent downtime.

- Collaborated with other team members to ensure a smooth and coordinated production process.

Accomplishments

- Successfully implemented a new pattern edge design that increased production efficiency by 15%.

- Achieved zero downtime during a critical production run by proactively identifying and resolving potential equipment issues.

- Developed and implemented a preventive maintenance program that extended the life of the pattern edger by 20%.

- Trained and mentored new employees on proper operating procedures, ensuring seamless production flow.

- Improved communication with production team, reducing production errors by 10%.

Certificates

- Certified Production Technician (CPT)

- CNC Programming and Operation Certification

- ISO 90012015 Quality Management System

- Certified Manufacturing Engineer (CMfgE)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Automatic Pattern Edger

- Highlight your proficiency in CNC machine operation and pattern creation.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, emphasizing the skills and experience most relevant to the position.

- Proofread your resume carefully before submitting it to potential employers.

Essential Experience Highlights for a Strong Automatic Pattern Edger Resume

- Operate and calibrate CNC pattern edging machines to produce intricate patterns on metal sheets

- Develop and refine complex patterns using AutoCAD and other design software

- Set up and maintain machinery, ensuring optimal performance and accuracy

- Perform quality control inspections to ensure that products meet specifications

- Adhere to geometric tolerancing principles to achieve precise dimensions

- Collaborate with engineers and designers to optimize processes and improve product quality

- Train and supervise junior staff on machine operation and maintenance procedures

Frequently Asked Questions (FAQ’s) For Automatic Pattern Edger

What is the role of an Automatic Pattern Edger?

An Automatic Pattern Edger is responsible for operating and maintaining CNC machines to create complex patterns on metal sheets. They also develop and refine patterns using design software, set up and maintain machinery, and perform quality control inspections. Automatic Pattern Edgers play a crucial role in the manufacturing process by ensuring that products meet specifications and are produced efficiently.

What are the key skills required for an Automatic Pattern Edger?

The key skills required for an Automatic Pattern Edger include CNC machine operation, pattern creation, machine setup and calibration, quality control, geometric tolerancing, and AutoCAD. Automatic Pattern Edgers should also have a strong understanding of manufacturing processes and be able to work independently and as part of a team.

What are the career prospects for an Automatic Pattern Edger?

Automatic Pattern Edgers can advance their careers by becoming supervisors or managers in the manufacturing industry. They may also specialize in a particular area, such as CNC programming or quality control. With experience and additional training, Automatic Pattern Edgers can also move into related fields, such as engineering or design.

What is the work environment like for an Automatic Pattern Edger?

Automatic Pattern Edgers typically work in a manufacturing environment, which can be noisy and dusty. They may also work in a variety of temperatures, depending on the specific industry. Automatic Pattern Edgers should be able to work independently and as part of a team, and they should be able to meet deadlines and work under pressure.

What are the educational requirements for an Automatic Pattern Edger?

Most Automatic Pattern Edgers have a high school diploma or equivalent. Some employers may prefer candidates with a college degree in a related field, such as mechanical engineering or manufacturing technology. Automatic Pattern Edgers can also gain the necessary skills through on-the-job training or apprenticeships.