Are you a seasoned Automatic Splicing Machine Operator seeking a new career path? Discover our professionally built Automatic Splicing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

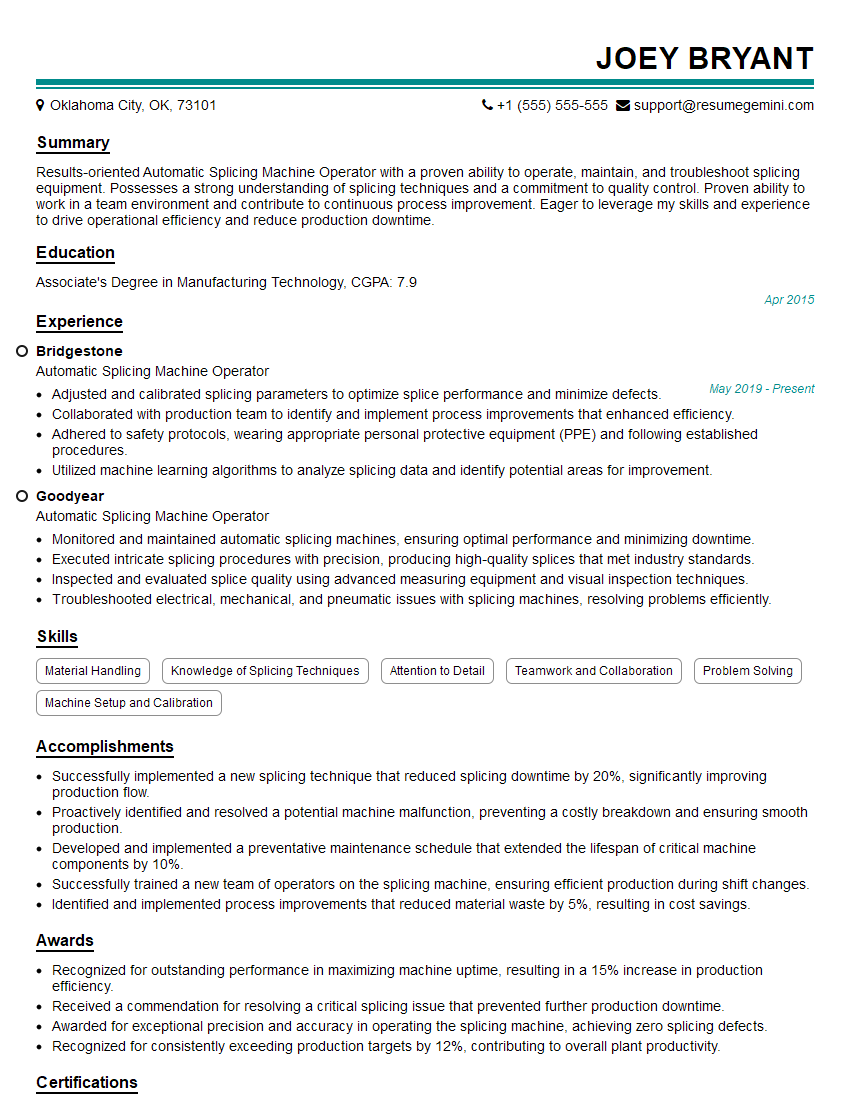

Joey Bryant

Automatic Splicing Machine Operator

Summary

Results-oriented Automatic Splicing Machine Operator with a proven ability to operate, maintain, and troubleshoot splicing equipment. Possesses a strong understanding of splicing techniques and a commitment to quality control. Proven ability to work in a team environment and contribute to continuous process improvement. Eager to leverage my skills and experience to drive operational efficiency and reduce production downtime.

Education

Associate’s Degree in Manufacturing Technology

April 2015

Skills

- Material Handling

- Knowledge of Splicing Techniques

- Attention to Detail

- Teamwork and Collaboration

- Problem Solving

- Machine Setup and Calibration

Work Experience

Automatic Splicing Machine Operator

- Adjusted and calibrated splicing parameters to optimize splice performance and minimize defects.

- Collaborated with production team to identify and implement process improvements that enhanced efficiency.

- Adhered to safety protocols, wearing appropriate personal protective equipment (PPE) and following established procedures.

- Utilized machine learning algorithms to analyze splicing data and identify potential areas for improvement.

Automatic Splicing Machine Operator

- Monitored and maintained automatic splicing machines, ensuring optimal performance and minimizing downtime.

- Executed intricate splicing procedures with precision, producing high-quality splices that met industry standards.

- Inspected and evaluated splice quality using advanced measuring equipment and visual inspection techniques.

- Troubleshooted electrical, mechanical, and pneumatic issues with splicing machines, resolving problems efficiently.

Accomplishments

- Successfully implemented a new splicing technique that reduced splicing downtime by 20%, significantly improving production flow.

- Proactively identified and resolved a potential machine malfunction, preventing a costly breakdown and ensuring smooth production.

- Developed and implemented a preventative maintenance schedule that extended the lifespan of critical machine components by 10%.

- Successfully trained a new team of operators on the splicing machine, ensuring efficient production during shift changes.

- Identified and implemented process improvements that reduced material waste by 5%, resulting in cost savings.

Awards

- Recognized for outstanding performance in maximizing machine uptime, resulting in a 15% increase in production efficiency.

- Received a commendation for resolving a critical splicing issue that prevented further production downtime.

- Awarded for exceptional precision and accuracy in operating the splicing machine, achieving zero splicing defects.

- Recognized for consistently exceeding production targets by 12%, contributing to overall plant productivity.

Certificates

- Certified Automatic Splicing Machine Operator (CASMO)

- OSHA 10Hour General Industry

- Forklift Operator Certification

- Pallet Jack Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Automatic Splicing Machine Operator

- Highlight your technical skills and experience in operating and maintaining splicing machines.

- Quantify your accomplishments with specific metrics to demonstrate your impact on production efficiency.

- Emphasize your problem-solving abilities and provide examples of how you have resolved machine malfunctions.

- Showcase your commitment to continuous improvement and your involvement in process optimization initiatives.

- Tailor your resume to the specific requirements of the job description.

Essential Experience Highlights for a Strong Automatic Splicing Machine Operator Resume

- Operate automatic splicing machines to join materials with precision and accuracy.

- Monitor production processes and make adjustments to ensure optimal performance.

- Troubleshoot and resolve machine malfunctions, including mechanical, electrical, and pneumatic issues.

- Perform preventative maintenance on splicing equipment to extend its lifespan and minimize downtime.

- Collaborate with production team members to optimize production flow and meet quality standards.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Automatic Splicing Machine Operator

What are the primary responsibilities of an Automatic Splicing Machine Operator?

The primary responsibilities of an Automatic Splicing Machine Operator include operating, maintaining, and troubleshooting automatic splicing machines to ensure precise and efficient joining of materials. They monitor production processes, resolve machine malfunctions, perform preventative maintenance, collaborate with team members, and adhere to safety protocols.

What are the essential skills required to succeed as an Automatic Splicing Machine Operator?

Essential skills for an Automatic Splicing Machine Operator include proficiency in operating and maintaining splicing machines, troubleshooting mechanical, electrical, and pneumatic issues, performing preventative maintenance, and adhering to safety protocols. Strong attention to detail, problem-solving abilities, and a commitment to quality are also crucial.

What are the career prospects for an Automatic Splicing Machine Operator?

Automatic Splicing Machine Operators can advance their careers by becoming trainers, supervisors, or production managers. With experience and additional training, they can also move into roles such as quality control inspectors, process engineers, or maintenance technicians.

What are the common challenges faced by Automatic Splicing Machine Operators?

Common challenges faced by Automatic Splicing Machine Operators include maintaining high production rates while ensuring product quality, troubleshooting and resolving machine malfunctions, and working in a fast-paced and demanding production environment.

What is the expected salary range for an Automatic Splicing Machine Operator?

The salary range for an Automatic Splicing Machine Operator can vary based on factors such as experience, location, and industry. According to Salary.com, the average annual salary for an Automatic Splicing Machine Operator in the United States is around $45,000.

What are the educational requirements for becoming an Automatic Splicing Machine Operator?

While formal education is not always required, many Automatic Splicing Machine Operators have an associate’s degree or certificate in manufacturing technology, mechanical engineering, or a related field. Hands-on training and experience in operating and maintaining splicing machines are also valuable.

What are the key qualities of a successful Automatic Splicing Machine Operator?

Successful Automatic Splicing Machine Operators are typically detail-oriented, have strong problem-solving abilities, and are committed to maintaining a clean and organized work area. They are also able to work independently and as part of a team, and are adaptable to changing production demands.