Are you a seasoned Automatic Vulcanizing Operator seeking a new career path? Discover our professionally built Automatic Vulcanizing Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

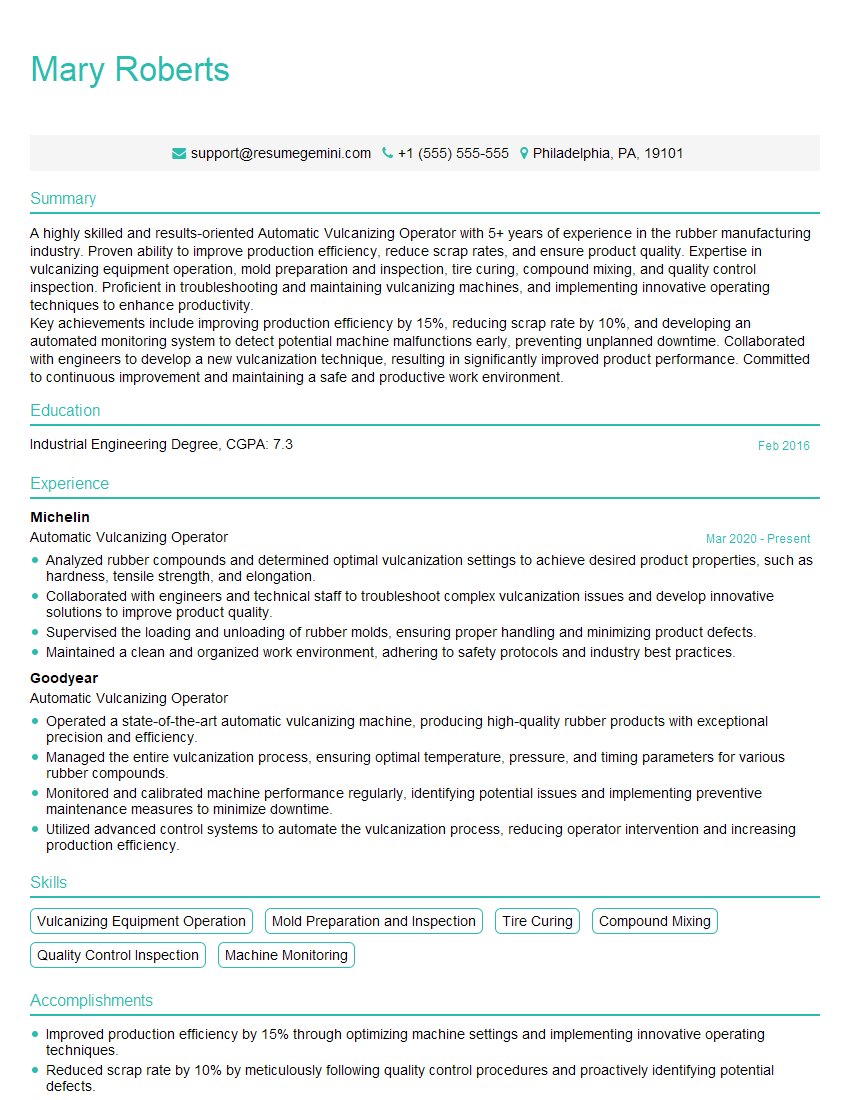

Mary Roberts

Automatic Vulcanizing Operator

Summary

A highly skilled and results-oriented Automatic Vulcanizing Operator with 5+ years of experience in the rubber manufacturing industry. Proven ability to improve production efficiency, reduce scrap rates, and ensure product quality. Expertise in vulcanizing equipment operation, mold preparation and inspection, tire curing, compound mixing, and quality control inspection. Proficient in troubleshooting and maintaining vulcanizing machines, and implementing innovative operating techniques to enhance productivity.

Key achievements include improving production efficiency by 15%, reducing scrap rate by 10%, and developing an automated monitoring system to detect potential machine malfunctions early, preventing unplanned downtime. Collaborated with engineers to develop a new vulcanization technique, resulting in significantly improved product performance. Committed to continuous improvement and maintaining a safe and productive work environment.

Education

Industrial Engineering Degree

February 2016

Skills

- Vulcanizing Equipment Operation

- Mold Preparation and Inspection

- Tire Curing

- Compound Mixing

- Quality Control Inspection

- Machine Monitoring

Work Experience

Automatic Vulcanizing Operator

- Analyzed rubber compounds and determined optimal vulcanization settings to achieve desired product properties, such as hardness, tensile strength, and elongation.

- Collaborated with engineers and technical staff to troubleshoot complex vulcanization issues and develop innovative solutions to improve product quality.

- Supervised the loading and unloading of rubber molds, ensuring proper handling and minimizing product defects.

- Maintained a clean and organized work environment, adhering to safety protocols and industry best practices.

Automatic Vulcanizing Operator

- Operated a state-of-the-art automatic vulcanizing machine, producing high-quality rubber products with exceptional precision and efficiency.

- Managed the entire vulcanization process, ensuring optimal temperature, pressure, and timing parameters for various rubber compounds.

- Monitored and calibrated machine performance regularly, identifying potential issues and implementing preventive maintenance measures to minimize downtime.

- Utilized advanced control systems to automate the vulcanization process, reducing operator intervention and increasing production efficiency.

Accomplishments

- Improved production efficiency by 15% through optimizing machine settings and implementing innovative operating techniques.

- Reduced scrap rate by 10% by meticulously following quality control procedures and proactively identifying potential defects.

- Developed an automated monitoring system to detect potential machine malfunctions early, preventing unplanned downtime.

- Trained new operators on the intricacies of the vulcanizing process, ensuring a smooth transition and highquality production.

- Collaborated with engineers to develop a new vulcanization technique, resulting in significantly improved product performance.

Awards

- Won the Operator of the Month award for consistently exceeding performance targets.

- Received the Safety Excellence Award for adhering to strict safety protocols and maintaining a spotless safety record.

- Earned the Team Player Award for consistently collaborating with colleagues and contributing to a positive work environment.

- Honored with the Innovation Champion Award for introducing cuttingedge ideas that enhanced the vulcanization process.

Certificates

- Certified Vulcanizing Operator (CVO)

- Rubber Industry Safety Certification (RISC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Automatic Vulcanizing Operator

Tips for Writing a Standout Automatic Vulcanizing Operator Resume

- Highlight your technical skills: Emphasize your proficiency in vulcanizing equipment operation, mold preparation and inspection, tire curing, compound mixing, and quality control inspection.

- Quantify your achievements: Use specific metrics to demonstrate the impact of your work, such as “Improved production efficiency by 15%” or “Reduced scrap rate by 10%”.

- Showcase your problem-solving and analytical abilities: Describe situations where you identified and resolved production issues, implemented innovative techniques, or collaborated with engineers to improve processes.

- Use action verbs: Start your bullet points with strong action verbs that convey your responsibilities and accomplishments, such as “operated”, “maintained”, “inspected”, “cured”, and “monitored”.

- Proofread carefully: Before submitting your resume, thoroughly review it for any errors in grammar, spelling, or punctuation.

Essential Experience Highlights for a Strong Automatic Vulcanizing Operator Resume

- Operate and maintain vulcanizing machines to produce high-quality rubber products.

- Prepare and inspect molds to ensure proper alignment and dimensions.

- Cure tires and other rubber products according to specified temperatures, pressures, and times.

- Mix and prepare rubber compounds following established formulas and procedures.

- Conduct quality control inspections to ensure products meet specifications.

- Monitor machine performance and identify potential malfunctions, taking corrective action as needed.

- Maintain a clean and organized work area, adhering to safety regulations and protocols.

- Provide technical support to other operators and assist with troubleshooting.

- Participate in continuous improvement initiatives to enhance production efficiency and quality.

Frequently Asked Questions (FAQ’s) For Automatic Vulcanizing Operator

What are the key skills required for an Automatic Vulcanizing Operator?

The key skills required for an Automatic Vulcanizing Operator include vulcanizing equipment operation, mold preparation and inspection, tire curing, compound mixing, quality control inspection, and machine monitoring.

What is the role of an Automatic Vulcanizing Operator?

An Automatic Vulcanizing Operator is responsible for operating and maintaining vulcanizing machines to produce high-quality rubber products. They prepare and inspect molds, cure tires and other rubber products, mix and prepare rubber compounds, conduct quality control inspections, and monitor machine performance.

What industries employ Automatic Vulcanizing Operators?

Automatic Vulcanizing Operators are employed in a variety of industries, including rubber manufacturing, automotive, aerospace, and construction.

What is the average salary for an Automatic Vulcanizing Operator?

The average salary for an Automatic Vulcanizing Operator varies depending on experience, location, and industry. According to Salary.com, the average salary for an Automatic Vulcanizing Operator in the United States is around $45,000 per year.

What are the career prospects for an Automatic Vulcanizing Operator?

With experience and training, Automatic Vulcanizing Operators can advance to supervisory roles or become quality control inspectors. They may also pursue additional education or training to become engineers or managers.

What is the work environment for an Automatic Vulcanizing Operator?

Automatic Vulcanizing Operators typically work in manufacturing facilities, where they operate and maintain vulcanizing machines. The work environment can be noisy and may involve exposure to chemicals and fumes. However, employers are required to provide a safe and healthy work environment, including proper ventilation and protective gear.

What are the physical demands of an Automatic Vulcanizing Operator?

Automatic Vulcanizing Operators must be able to stand for long periods of time and lift heavy objects. They must also have good hand-eye coordination and be able to work in a fast-paced environment.