Are you a seasoned Back Strip Machine Operator seeking a new career path? Discover our professionally built Back Strip Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

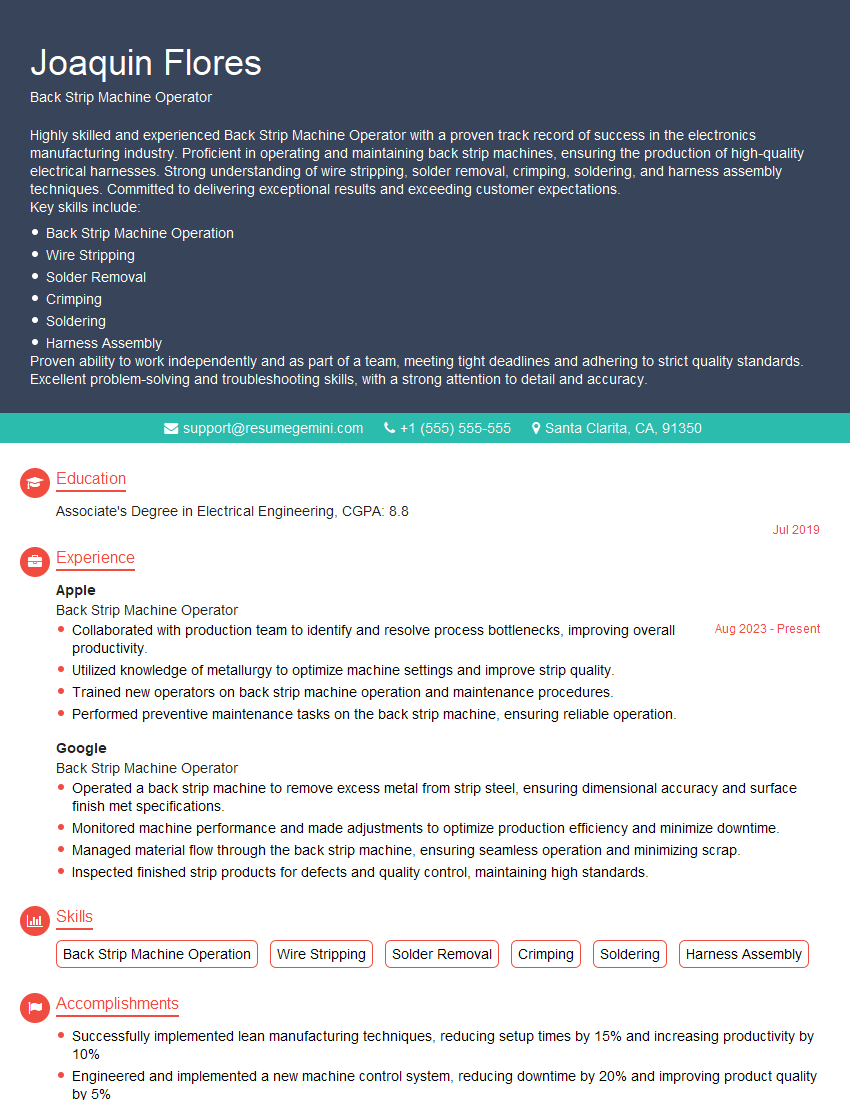

Joaquin Flores

Back Strip Machine Operator

Summary

Highly skilled and experienced Back Strip Machine Operator with a proven track record of success in the electronics manufacturing industry. Proficient in operating and maintaining back strip machines, ensuring the production of high-quality electrical harnesses. Strong understanding of wire stripping, solder removal, crimping, soldering, and harness assembly techniques. Committed to delivering exceptional results and exceeding customer expectations.

Key skills include:

- Back Strip Machine Operation

- Wire Stripping

- Solder Removal

- Crimping

- Soldering

- Harness Assembly

Proven ability to work independently and as part of a team, meeting tight deadlines and adhering to strict quality standards. Excellent problem-solving and troubleshooting skills, with a strong attention to detail and accuracy.

Education

Associate’s Degree in Electrical Engineering

July 2019

Skills

- Back Strip Machine Operation

- Wire Stripping

- Solder Removal

- Crimping

- Soldering

- Harness Assembly

Work Experience

Back Strip Machine Operator

- Collaborated with production team to identify and resolve process bottlenecks, improving overall productivity.

- Utilized knowledge of metallurgy to optimize machine settings and improve strip quality.

- Trained new operators on back strip machine operation and maintenance procedures.

- Performed preventive maintenance tasks on the back strip machine, ensuring reliable operation.

Back Strip Machine Operator

- Operated a back strip machine to remove excess metal from strip steel, ensuring dimensional accuracy and surface finish met specifications.

- Monitored machine performance and made adjustments to optimize production efficiency and minimize downtime.

- Managed material flow through the back strip machine, ensuring seamless operation and minimizing scrap.

- Inspected finished strip products for defects and quality control, maintaining high standards.

Accomplishments

- Successfully implemented lean manufacturing techniques, reducing setup times by 15% and increasing productivity by 10%

- Engineered and implemented a new machine control system, reducing downtime by 20% and improving product quality by 5%

- Led a team of operators in developing and implementing new safety protocols, resulting in a 50% reduction in workplace accidents

- Trained and mentored new employees, ensuring onboarding success and compliance with all safety regulations

- Identified and resolved mechanical issues with back strip machine, preventing costly downtime and ensuring continuous production

Awards

- Award for outstanding performance in back strip machine operation practices, exceeding production targets by 25%

Certificates

- Certified IPC-A-610 Specialist (CIS)

- Certified IPC-A-620 Instructor (CII)

- Certified IPC-WHMA-A-620 Trainer (CWT)

- Certified IPC-6012 Electronics Assembly Technician (CEAT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Back Strip Machine Operator

- Highlight your experience and skills in operating back strip machines.

- Showcase your knowledge of wire stripping, solder removal, crimping, soldering, and harness assembly techniques.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Back Strip Machine Operator Resume

- Operate and maintain back strip machines to remove insulation from wire ends

- Strip wires to precise lengths and specifications using wire strippers

- Remove solder from wire ends using solder removal tools

- Crimp wire terminals and connectors using crimping tools

- Solder wires together to create electrical connections

- Assemble electrical harnesses according to engineering drawings and specifications

- Inspect finished harnesses for quality and accuracy

Frequently Asked Questions (FAQ’s) For Back Strip Machine Operator

What is a Back Strip Machine Operator?

A Back Strip Machine Operator is responsible for operating and maintaining back strip machines, which are used to remove insulation from wire ends. They also strip wires to precise lengths and specifications, remove solder from wire ends, crimp wire terminals and connectors, solder wires together to create electrical connections, and assemble electrical harnesses according to engineering drawings and specifications.

What are the key skills required for a Back Strip Machine Operator?

The key skills required for a Back Strip Machine Operator include: back strip machine operation, wire stripping, solder removal, crimping, soldering, harness assembly, and attention to detail.

What is the work environment of a Back Strip Machine Operator like?

Back Strip Machine Operators typically work in a manufacturing environment, where they may be exposed to noise, dust, and chemicals. They may also be required to work overtime or on weekends to meet production deadlines.

What are the career prospects for a Back Strip Machine Operator?

Back Strip Machine Operators can advance to positions such as Lead Operator, Supervisor, or Manager. They may also move into other areas of the electronics manufacturing industry, such as quality control or engineering.

How can I become a Back Strip Machine Operator?

To become a Back Strip Machine Operator, you will typically need a high school diploma or equivalent and some experience in the electronics manufacturing industry. You can also take courses in wire stripping, soldering, and harness assembly to improve your skills.

What are the salary expectations for a Back Strip Machine Operator?

The salary expectations for a Back Strip Machine Operator will vary depending on their experience, skills, and location. However, the median annual salary for Back Strip Machine Operators is around \$35,000.

What are the benefits of being a Back Strip Machine Operator?

The benefits of being a Back Strip Machine Operator include: job security, competitive salary, and opportunities for advancement. Back Strip Machine Operators are also in high demand, which means there are plenty of job opportunities available.