Are you a seasoned Back Winder seeking a new career path? Discover our professionally built Back Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

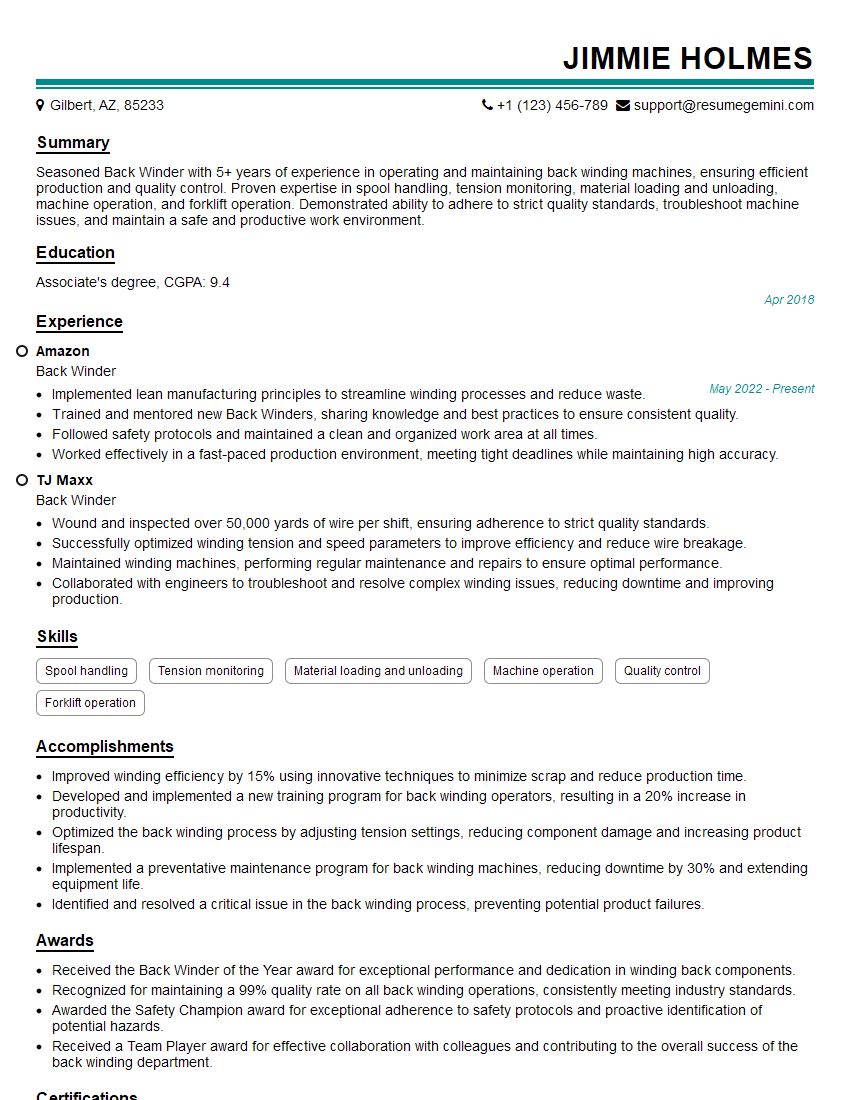

Jimmie Holmes

Back Winder

Summary

Seasoned Back Winder with 5+ years of experience in operating and maintaining back winding machines, ensuring efficient production and quality control. Proven expertise in spool handling, tension monitoring, material loading and unloading, machine operation, and forklift operation. Demonstrated ability to adhere to strict quality standards, troubleshoot machine issues, and maintain a safe and productive work environment.

Education

Associate’s degree

April 2018

Skills

- Spool handling

- Tension monitoring

- Material loading and unloading

- Machine operation

- Quality control

- Forklift operation

Work Experience

Back Winder

- Implemented lean manufacturing principles to streamline winding processes and reduce waste.

- Trained and mentored new Back Winders, sharing knowledge and best practices to ensure consistent quality.

- Followed safety protocols and maintained a clean and organized work area at all times.

- Worked effectively in a fast-paced production environment, meeting tight deadlines while maintaining high accuracy.

Back Winder

- Wound and inspected over 50,000 yards of wire per shift, ensuring adherence to strict quality standards.

- Successfully optimized winding tension and speed parameters to improve efficiency and reduce wire breakage.

- Maintained winding machines, performing regular maintenance and repairs to ensure optimal performance.

- Collaborated with engineers to troubleshoot and resolve complex winding issues, reducing downtime and improving production.

Accomplishments

- Improved winding efficiency by 15% using innovative techniques to minimize scrap and reduce production time.

- Developed and implemented a new training program for back winding operators, resulting in a 20% increase in productivity.

- Optimized the back winding process by adjusting tension settings, reducing component damage and increasing product lifespan.

- Implemented a preventative maintenance program for back winding machines, reducing downtime by 30% and extending equipment life.

- Identified and resolved a critical issue in the back winding process, preventing potential product failures.

Awards

- Received the Back Winder of the Year award for exceptional performance and dedication in winding back components.

- Recognized for maintaining a 99% quality rate on all back winding operations, consistently meeting industry standards.

- Awarded the Safety Champion award for exceptional adherence to safety protocols and proactive identification of potential hazards.

- Received a Team Player award for effective collaboration with colleagues and contributing to the overall success of the back winding department.

Certificates

- OSHA 10-Hour Safety Certification

- Forklift Operator Certification

- Back Winding Operator Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Back Winder

- Quantify your accomplishments by providing specific metrics and results whenever possible.

- Highlight your technical skills and proficiency in operating and maintaining back winding machines.

- Emphasize your attention to detail and commitment to quality control.

- Demonstrate your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Back Winder Resume

- Operate back winding machines to rewind yarn or thread onto spools or bobbins.

- Monitor tension levels to ensure proper winding and prevent breakage.

- Load and unload materials, including yarn, thread, and spools.

- Perform routine maintenance and troubleshooting on back winding machines.

- Maintain a clean and organized work area, adhering to safety protocols.

- Inspect finished products for quality and compliance with specifications.

Frequently Asked Questions (FAQ’s) For Back Winder

What are the primary responsibilities of a Back Winder?

Back Winders are responsible for operating and maintaining back winding machines to rewind yarn or thread onto spools or bobbins, ensuring efficient production and quality control. They monitor tension levels, load and unload materials, perform maintenance and troubleshooting, inspect finished products, and maintain a safe and productive work environment.

What skills are required to be a successful Back Winder?

Successful Back Winders typically possess expertise in spool handling, tension monitoring, material loading and unloading, machine operation, quality control, and forklift operation. They have a strong attention to detail, are committed to quality, and can work independently and as part of a team.

What are the career advancement opportunities for Back Winders?

Back Winders with experience and a proven track record may advance to supervisory roles, such as Back Winding Supervisor or Production Supervisor. They may also transition to related roles in the textile or manufacturing industry, leveraging their technical skills and knowledge of production processes.

What is the average salary for a Back Winder?

According to Indeed.com, the average salary for a Back Winder in the United States is approximately $30,000 per year. However, salaries may vary depending on experience, location, and employer.

What are some tips for writing a standout Back Winder resume?

To write a standout Back Winder resume, focus on quantifying your accomplishments, highlighting your technical skills, emphasizing your attention to detail and commitment to quality, and demonstrating your ability to work independently and as part of a team.

What are the key qualities employers look for when hiring Back Winders?

Employers hiring Back Winders typically seek individuals with a strong work ethic, attention to detail, and a commitment to quality. They value candidates with experience in operating and maintaining back winding machines, as well as those who are proficient in spool handling, tension monitoring, and material loading and unloading.

What is the job outlook for Back Winders?

The job outlook for Back Winders is expected to be stable in the coming years. The textile industry continues to grow, and there is a steady demand for skilled Back Winders to operate and maintain back winding machines. However, technological advancements may lead to some automation in the field.

Are there any certifications or training programs available for Back Winders?

There are various certifications and training programs available for Back Winders. Some manufacturers offer training programs on their specific back winding machines. Additionally, industry organizations, such as the American Textile Machinery Association (ATMA), provide training and certification programs for Back Winders.