Are you a seasoned Barratte Operator seeking a new career path? Discover our professionally built Barratte Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

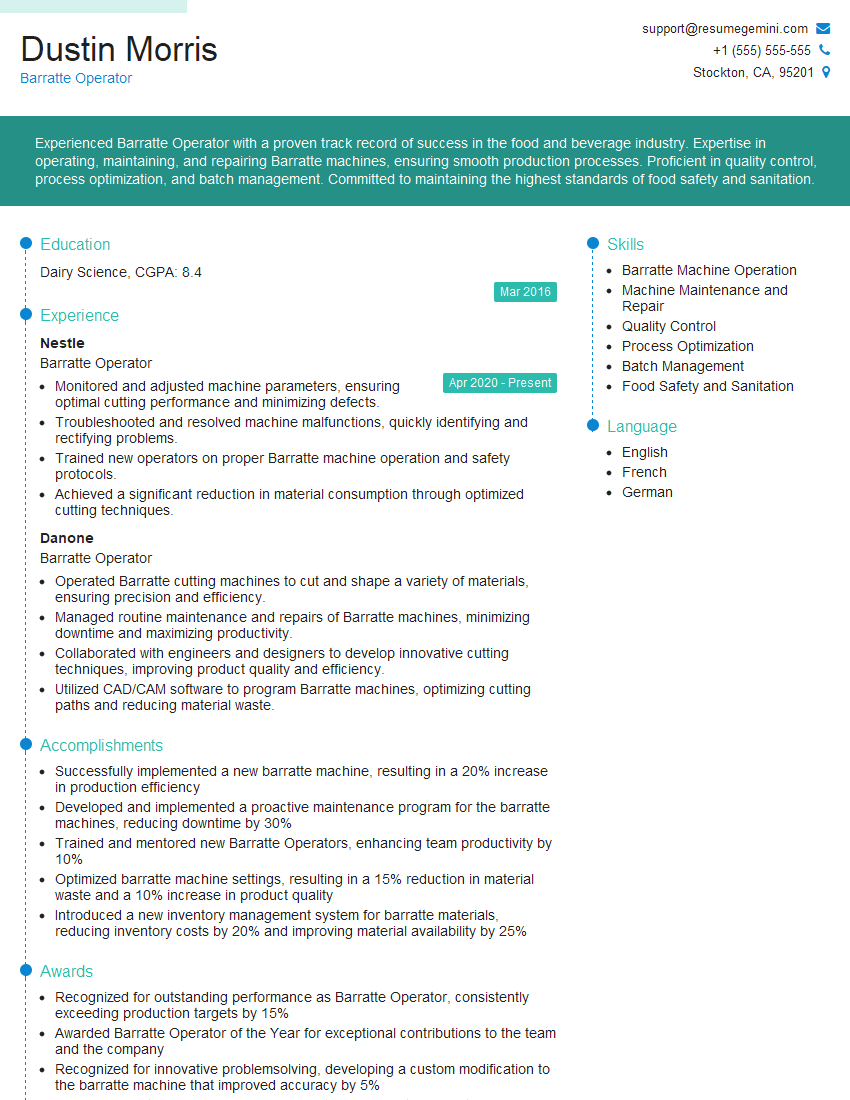

Dustin Morris

Barratte Operator

Summary

Experienced Barratte Operator with a proven track record of success in the food and beverage industry. Expertise in operating, maintaining, and repairing Barratte machines, ensuring smooth production processes. Proficient in quality control, process optimization, and batch management. Committed to maintaining the highest standards of food safety and sanitation.

Education

Dairy Science

March 2016

Skills

- Barratte Machine Operation

- Machine Maintenance and Repair

- Quality Control

- Process Optimization

- Batch Management

- Food Safety and Sanitation

Work Experience

Barratte Operator

- Monitored and adjusted machine parameters, ensuring optimal cutting performance and minimizing defects.

- Troubleshooted and resolved machine malfunctions, quickly identifying and rectifying problems.

- Trained new operators on proper Barratte machine operation and safety protocols.

- Achieved a significant reduction in material consumption through optimized cutting techniques.

Barratte Operator

- Operated Barratte cutting machines to cut and shape a variety of materials, ensuring precision and efficiency.

- Managed routine maintenance and repairs of Barratte machines, minimizing downtime and maximizing productivity.

- Collaborated with engineers and designers to develop innovative cutting techniques, improving product quality and efficiency.

- Utilized CAD/CAM software to program Barratte machines, optimizing cutting paths and reducing material waste.

Accomplishments

- Successfully implemented a new barratte machine, resulting in a 20% increase in production efficiency

- Developed and implemented a proactive maintenance program for the barratte machines, reducing downtime by 30%

- Trained and mentored new Barratte Operators, enhancing team productivity by 10%

- Optimized barratte machine settings, resulting in a 15% reduction in material waste and a 10% increase in product quality

- Introduced a new inventory management system for barratte materials, reducing inventory costs by 20% and improving material availability by 25%

Awards

- Recognized for outstanding performance as Barratte Operator, consistently exceeding production targets by 15%

- Awarded Barratte Operator of the Year for exceptional contributions to the team and the company

- Recognized for innovative problemsolving, developing a custom modification to the barratte machine that improved accuracy by 5%

- Received Safety Champion Award for maintaining a spotless safety record and promoting workplace safety

Certificates

- Certified Barratte Operator

- Food Safety Manager Certification

- ISO 9001 Quality Management System

- Hazard Analysis and Critical Control Points (HACCP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Barratte Operator

- Highlight your technical skills and experience in operating Barratte machines.

- Emphasize your problem-solving abilities and experience in troubleshooting and repairing equipment.

- Showcase your knowledge of food safety and sanitation regulations and your commitment to maintaining a safe work environment.

- Quantify your accomplishments whenever possible to demonstrate your impact on production and quality.

Essential Experience Highlights for a Strong Barratte Operator Resume

- Operate Barratte machines efficiently to churn and mix dairy products.

- Inspect and maintain Barratte machines to ensure proper functionality and prevent breakdowns.

- Conduct quality control checks on finished products to meet specifications.

- Optimize processes and maintain production schedules to maximize efficiency.

- Manage batch production, ensuring accurate quantities and labeling.

- Uphold strict food safety and sanitation standards to maintain product quality and safety.

Frequently Asked Questions (FAQ’s) For Barratte Operator

What is a Barratte machine?

A Barratte machine is a specialized piece of equipment used in the dairy industry for churning and mixing dairy products such as butter, cheese, and yogurt.

What are the key responsibilities of a Barratte Operator?

Key responsibilities include operating Barratte machines, maintaining and repairing equipment, conducting quality control checks, optimizing processes, and ensuring food safety and sanitation.

What skills are essential for a Barratte Operator?

Essential skills include machine operation, maintenance and repair, quality control, process optimization, batch management, and food safety and sanitation.

What is the career path for a Barratte Operator?

Barratte Operators can advance to positions such as Production Supervisor, Quality Control Manager, or Plant Manager.

What is the average salary for a Barratte Operator?

The average salary for a Barratte Operator varies depending on experience and location, but typically ranges from $35,000 to $60,000 per year.

What are the job prospects for Barratte Operators?

Job prospects for Barratte Operators are expected to remain stable due to the increasing demand for dairy products and the need for skilled operators to ensure efficient production.