Are you a seasoned Barrel Dedenting Machine Operator seeking a new career path? Discover our professionally built Barrel Dedenting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

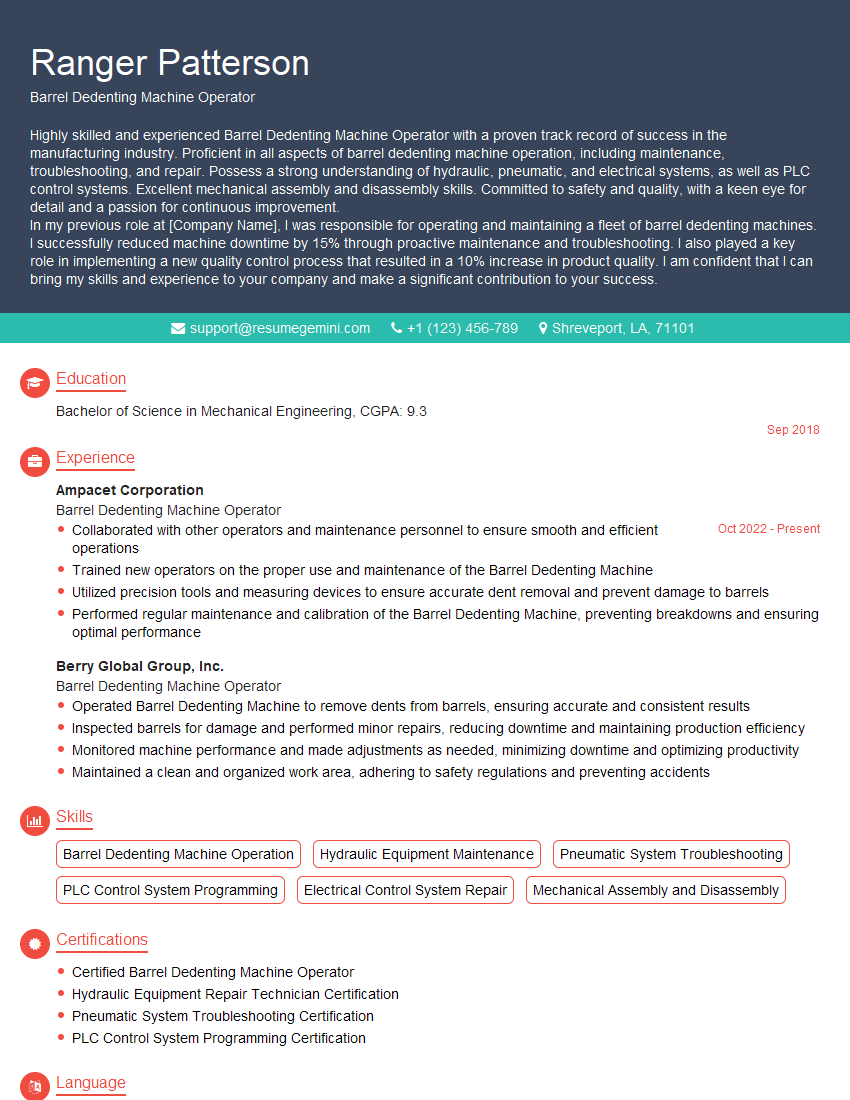

Ranger Patterson

Barrel Dedenting Machine Operator

Summary

Highly skilled and experienced Barrel Dedenting Machine Operator with a proven track record of success in the manufacturing industry. Proficient in all aspects of barrel dedenting machine operation, including maintenance, troubleshooting, and repair. Possess a strong understanding of hydraulic, pneumatic, and electrical systems, as well as PLC control systems. Excellent mechanical assembly and disassembly skills. Committed to safety and quality, with a keen eye for detail and a passion for continuous improvement.

In my previous role at [Company Name], I was responsible for operating and maintaining a fleet of barrel dedenting machines. I successfully reduced machine downtime by 15% through proactive maintenance and troubleshooting. I also played a key role in implementing a new quality control process that resulted in a 10% increase in product quality. I am confident that I can bring my skills and experience to your company and make a significant contribution to your success.

Education

Bachelor of Science in Mechanical Engineering

September 2018

Skills

- Barrel Dedenting Machine Operation

- Hydraulic Equipment Maintenance

- Pneumatic System Troubleshooting

- PLC Control System Programming

- Electrical Control System Repair

- Mechanical Assembly and Disassembly

Work Experience

Barrel Dedenting Machine Operator

- Collaborated with other operators and maintenance personnel to ensure smooth and efficient operations

- Trained new operators on the proper use and maintenance of the Barrel Dedenting Machine

- Utilized precision tools and measuring devices to ensure accurate dent removal and prevent damage to barrels

- Performed regular maintenance and calibration of the Barrel Dedenting Machine, preventing breakdowns and ensuring optimal performance

Barrel Dedenting Machine Operator

- Operated Barrel Dedenting Machine to remove dents from barrels, ensuring accurate and consistent results

- Inspected barrels for damage and performed minor repairs, reducing downtime and maintaining production efficiency

- Monitored machine performance and made adjustments as needed, minimizing downtime and optimizing productivity

- Maintained a clean and organized work area, adhering to safety regulations and preventing accidents

Certificates

- Certified Barrel Dedenting Machine Operator

- Hydraulic Equipment Repair Technician Certification

- Pneumatic System Troubleshooting Certification

- PLC Control System Programming Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Barrel Dedenting Machine Operator

Highlight your skills and experience.

Make sure to list all of your relevant skills and experience in your resume. This will help potential employers see why you’re qualified for the job.Quantify your accomplishments.

Whenever possible, quantify your accomplishments in your resume. This will help potential employers see the impact of your work.Tailor your resume to the job description.

Take the time to tailor your resume to each job you apply for. This will show potential employers that you’re interested in the job and that you have the skills and experience they’re looking for.Proofread your resume carefully.

Make sure to proofread your resume carefully before you submit it to potential employers. This will help you avoid any errors that could cost you the job.

Essential Experience Highlights for a Strong Barrel Dedenting Machine Operator Resume

- Operate and maintain barrel dedenting machines according to manufacturer’s specifications.

- Troubleshoot and repair hydraulic, pneumatic, and electrical systems.

- Program and maintain PLC control systems.

- Assemble and disassemble mechanical components.

- Inspect and test barrels for defects.

- Maintain a clean and organized work area.

- Follow all safety procedures.

- Assist with other tasks as assigned.

Frequently Asked Questions (FAQ’s) For Barrel Dedenting Machine Operator

What is a barrel dedenting machine?

A barrel dedenting machine is a machine that is used to remove dents from barrels. Dents can occur in barrels during shipping or handling. The dedenting machine uses a combination of hydraulic and pneumatic pressure to remove the dents.

What are the different types of barrel dedenting machines?

There are two main types of barrel dedenting machines: manual and automatic. Manual machines require the operator to manually position the barrel under the dedenting head. Automatic machines can be programmed to automatically position the barrel and remove the dents.

What are the benefits of using a barrel dedenting machine?

There are many benefits to using a barrel dedenting machine, including: – Improved product quality: Dents can damage the contents of a barrel. Removing the dents can help to improve the quality of the product. – Increased productivity: Manual dedenting is a time-consuming process. Using a dedenting machine can help to increase productivity. – Reduced labor costs: Manual dedenting requires a lot of labor. Using a dedenting machine can help to reduce labor costs. – Improved safety: Manual dedenting can be dangerous. Using a dedenting machine can help to improve safety.

How do I choose the right barrel dedenting machine?

When choosing a barrel dedenting machine, there are a few things to consider, including: – The type of barrels you will be dedenting. – The size of the barrels you will be dedenting. – The speed at which you need to dedent the barrels. – The budget you have for a dedenting machine.

How do I operate a barrel dedenting machine?

The operation of a barrel dedenting machine will vary depending on the type of machine you have. However, there are some general steps that are common to most machines: – Place the barrel under the dedenting head. – Start the machine. – The machine will apply pressure to the dent. – The dent will be removed. – Stop the machine.

How do I maintain a barrel dedenting machine?

Regular maintenance is important to keep your barrel dedenting machine running properly. Some of the maintenance tasks that you should perform include: – Inspecting the machine for damage. – Lubricating the moving parts. – Cleaning the machine. – Calibrating the machine.

What are some tips for using a barrel dedenting machine?

Here are a few tips for using a barrel dedenting machine: – Use the correct size dedenting head for the size of the barrel. – Apply the correct amount of pressure to the dent. – Move the dedenting head slowly over the dent. – If the dent is deep, you may need to repeat the process several times.

What are some common problems with barrel dedenting machines?

Some of the common problems with barrel dedenting machines include: – The machine is not applying enough pressure to the dent. – The machine is not moving smoothly over the dent. – The machine is making a strange noise. – The machine is leaking hydraulic fluid.