Are you a seasoned Barrel Plater seeking a new career path? Discover our professionally built Barrel Plater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

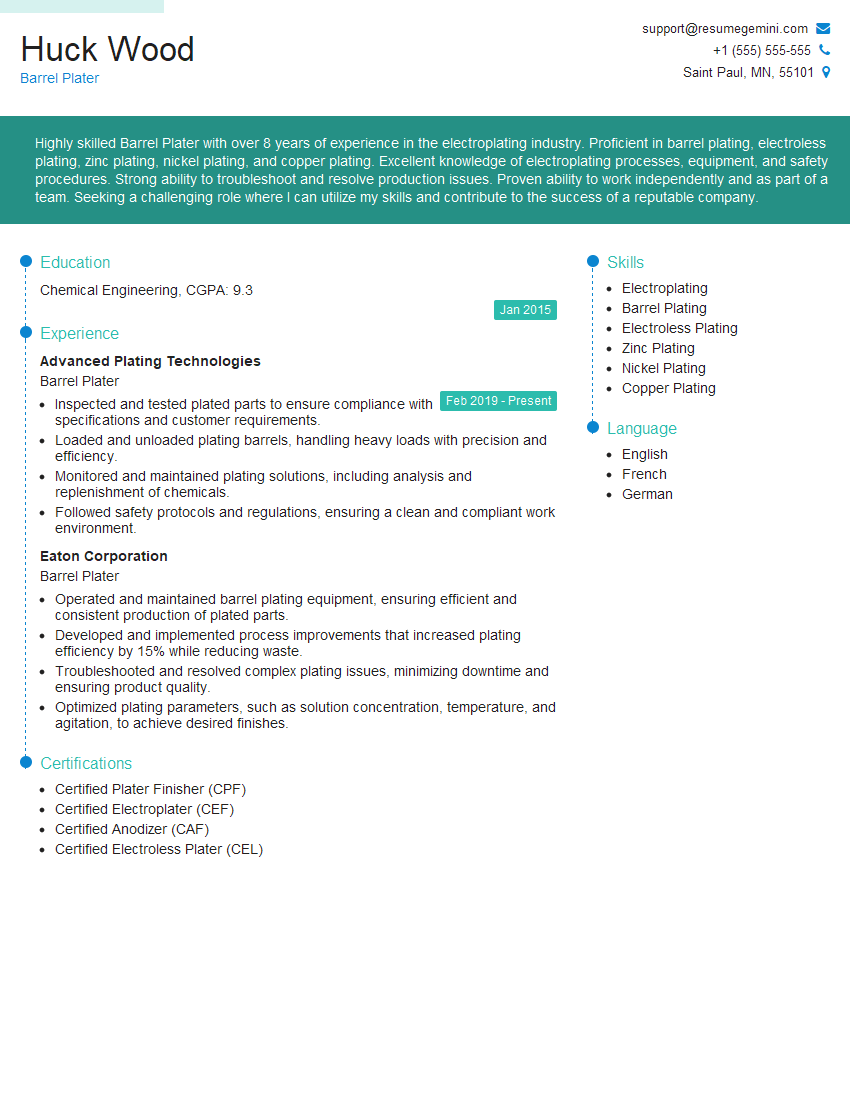

Huck Wood

Barrel Plater

Summary

Highly skilled Barrel Plater with over 8 years of experience in the electroplating industry. Proficient in barrel plating, electroless plating, zinc plating, nickel plating, and copper plating. Excellent knowledge of electroplating processes, equipment, and safety procedures. Strong ability to troubleshoot and resolve production issues. Proven ability to work independently and as part of a team. Seeking a challenging role where I can utilize my skills and contribute to the success of a reputable company.

Education

Chemical Engineering

January 2015

Skills

- Electroplating

- Barrel Plating

- Electroless Plating

- Zinc Plating

- Nickel Plating

- Copper Plating

Work Experience

Barrel Plater

- Inspected and tested plated parts to ensure compliance with specifications and customer requirements.

- Loaded and unloaded plating barrels, handling heavy loads with precision and efficiency.

- Monitored and maintained plating solutions, including analysis and replenishment of chemicals.

- Followed safety protocols and regulations, ensuring a clean and compliant work environment.

Barrel Plater

- Operated and maintained barrel plating equipment, ensuring efficient and consistent production of plated parts.

- Developed and implemented process improvements that increased plating efficiency by 15% while reducing waste.

- Troubleshooted and resolved complex plating issues, minimizing downtime and ensuring product quality.

- Optimized plating parameters, such as solution concentration, temperature, and agitation, to achieve desired finishes.

Certificates

- Certified Plater Finisher (CPF)

- Certified Electroplater (CEF)

- Certified Anodizer (CAF)

- Certified Electroless Plater (CEL)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Barrel Plater

- Highlight your experience and skills in barrel plating, electroless plating, and other relevant areas.

- Quantify your accomplishments using specific metrics, such as increased production efficiency or reduced downtime.

- Showcase your knowledge of electroplating processes and safety regulations.

- Emphasize your ability to work independently and as part of a team.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Barrel Plater Resume

- Operate and maintain barrel plating equipment, including loading, unloading, and cleaning

- Monitor plating processes and adjust parameters to ensure product quality

- Troubleshoot and resolve production issues, including identifying and correcting equipment malfunctions

- Maintain a safe and clean work environment, adhering to all safety regulations

- Supervise and train junior platers

- Coordinate with other departments, such as production and quality control, to ensure smooth production flow

- Keep detailed records of plating processes and production data

Frequently Asked Questions (FAQ’s) For Barrel Plater

What is barrel plating?

Barrel plating is a process of electroplating where small parts are placed in a rotating barrel and plated together. This process is often used for plating small, irregularly shaped parts.

What are the different types of barrel plating?

There are two main types of barrel plating: horizontal barrel plating and oblique barrel plating. Horizontal barrel plating is used for plating small, lightweight parts, while oblique barrel plating is used for plating larger, heavier parts.

What are the benefits of barrel plating?

Barrel plating offers several benefits, including: increased production efficiency, improved product quality, and reduced labor costs.

What are the challenges of barrel plating?

Barrel plating can be challenging due to the need to control the plating process and ensure that all parts are plated evenly. Additionally, barrel plating can generate hazardous waste, which must be properly disposed of.

What are the safety precautions that must be taken when barrel plating?

When barrel plating, it is important to take the following safety precautions: wear appropriate personal protective equipment, including gloves, eye protection, and a respirator; ensure that the plating equipment is properly grounded; and follow all safety procedures.

What are the career opportunities for barrel platers?

Barrel platers can find employment in a variety of industries, including automotive, electronics, and aerospace. With experience, barrel platers can advance to positions such as plating supervisor or quality control manager.