Are you a seasoned Basin Finish Operator-Tig Welder seeking a new career path? Discover our professionally built Basin Finish Operator-Tig Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

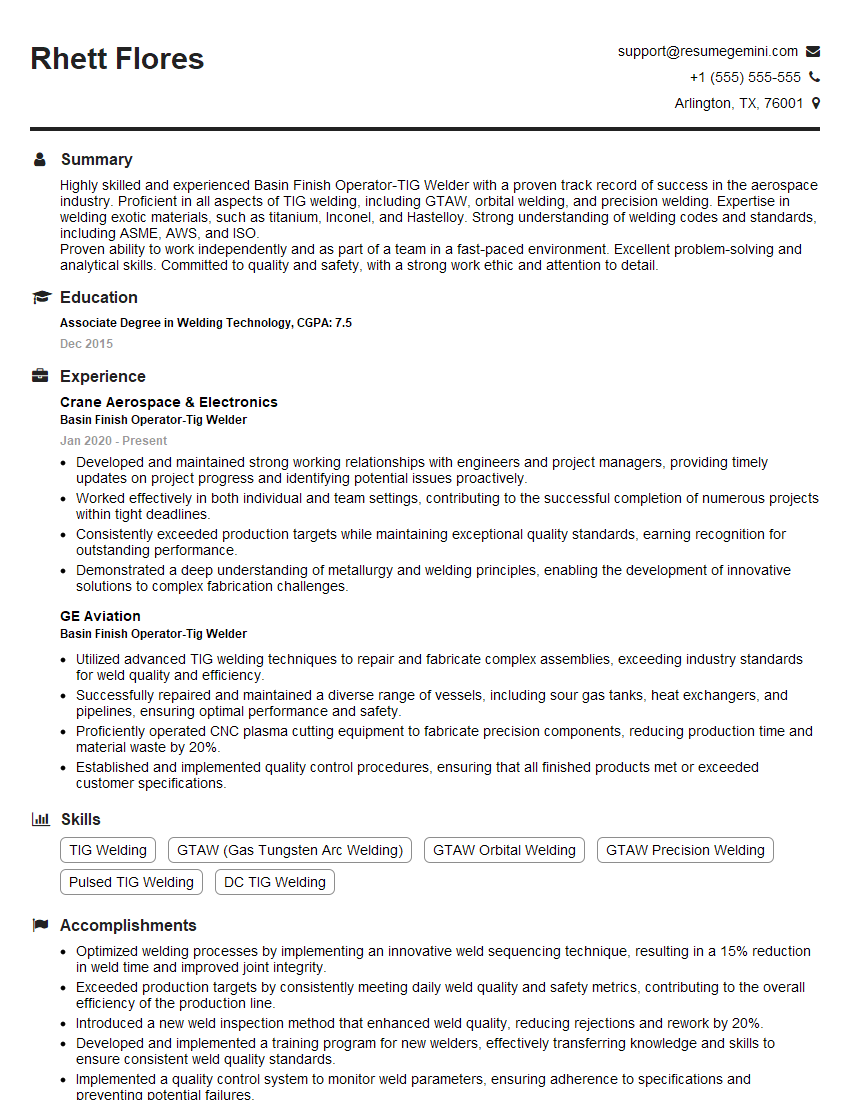

Rhett Flores

Basin Finish Operator-Tig Welder

Summary

Highly skilled and experienced Basin Finish Operator-TIG Welder with a proven track record of success in the aerospace industry. Proficient in all aspects of TIG welding, including GTAW, orbital welding, and precision welding. Expertise in welding exotic materials, such as titanium, Inconel, and Hastelloy. Strong understanding of welding codes and standards, including ASME, AWS, and ISO.

Proven ability to work independently and as part of a team in a fast-paced environment. Excellent problem-solving and analytical skills. Committed to quality and safety, with a strong work ethic and attention to detail.

Education

Associate Degree in Welding Technology

December 2015

Skills

- TIG Welding

- GTAW (Gas Tungsten Arc Welding)

- GTAW Orbital Welding

- GTAW Precision Welding

- Pulsed TIG Welding

- DC TIG Welding

Work Experience

Basin Finish Operator-Tig Welder

- Developed and maintained strong working relationships with engineers and project managers, providing timely updates on project progress and identifying potential issues proactively.

- Worked effectively in both individual and team settings, contributing to the successful completion of numerous projects within tight deadlines.

- Consistently exceeded production targets while maintaining exceptional quality standards, earning recognition for outstanding performance.

- Demonstrated a deep understanding of metallurgy and welding principles, enabling the development of innovative solutions to complex fabrication challenges.

Basin Finish Operator-Tig Welder

- Utilized advanced TIG welding techniques to repair and fabricate complex assemblies, exceeding industry standards for weld quality and efficiency.

- Successfully repaired and maintained a diverse range of vessels, including sour gas tanks, heat exchangers, and pipelines, ensuring optimal performance and safety.

- Proficiently operated CNC plasma cutting equipment to fabricate precision components, reducing production time and material waste by 20%.

- Established and implemented quality control procedures, ensuring that all finished products met or exceeded customer specifications.

Accomplishments

- Optimized welding processes by implementing an innovative weld sequencing technique, resulting in a 15% reduction in weld time and improved joint integrity.

- Exceeded production targets by consistently meeting daily weld quality and safety metrics, contributing to the overall efficiency of the production line.

- Introduced a new weld inspection method that enhanced weld quality, reducing rejections and rework by 20%.

- Developed and implemented a training program for new welders, effectively transferring knowledge and skills to ensure consistent weld quality standards.

- Implemented a quality control system to monitor weld parameters, ensuring adherence to specifications and preventing potential failures.

Awards

- Recognized with the Outstanding Welder Award for exceeding performance standards and maintaining the highest quality of workmanship.

- Awarded the Safety Excellence Award for consistently adhering to safety protocols and implementing proactive measures to prevent workplace hazards.

- Received the Employee of the Month Award for exceptional performance, dedication, and commitment to the team.

- Awarded the Innovation Award for developing a novel welding technique that improved weld strength and reduced production costs.

Certificates

- AWS Certified Welder – TIG

- ASME Boiler and Pressure Vessel Code Certified Welder – TIG

- API Certified Welder – TIG

- ISO 9001 Certified Welder – TIG

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Basin Finish Operator-Tig Welder

- Highlight your experience and skills in TIG welding, especially in welding exotic materials.

- Quantify your accomplishments whenever possible, using specific metrics and data.

- Showcase your understanding of welding codes and standards, and your commitment to quality and safety.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Basin Finish Operator-Tig Welder Resume

- Operate and maintain TIG welding equipment, including gas tungsten arc welding (GTAW), orbital welding, and precision welding.

- Weld exotic materials, such as titanium, Inconel, and Hastelloy, to exacting specifications.

- Inspect and ensure the quality of welds using visual and non-destructive testing methods.

- Troubleshoot and resolve welding problems, and develop and implement corrective actions.

- Maintain a clean and organized work area, and adhere to all safety protocols.

- Work independently and as part of a team to meet production goals and deadlines.

Frequently Asked Questions (FAQ’s) For Basin Finish Operator-Tig Welder

What is the role of a Basin Finish Operator-TIG Welder?

Basin Finish Operator-TIG Welders are responsible for operating and maintaining TIG welding equipment to weld exotic materials, such as titanium, Inconel, and Hastelloy, to exacting specifications. They inspect and ensure the quality of welds using visual and non-destructive testing methods, and troubleshoot and resolve welding problems.

What are the key skills required for a Basin Finish Operator-TIG Welder?

Key skills for a Basin Finish Operator-TIG Welder include proficiency in TIG welding, including GTAW, orbital welding, and precision welding. They must also have a strong understanding of welding codes and standards, and be able to work independently and as part of a team.

What are the career prospects for a Basin Finish Operator-TIG Welder?

Basin Finish Operator-TIG Welders are in high demand in the aerospace and other industries that require welding exotic materials. They can advance to supervisory or management positions, or specialize in a particular area of welding, such as orbital welding or precision welding.

What is the average salary for a Basin Finish Operator-TIG Welder?

The average salary for a Basin Finish Operator-TIG Welder in the United States is around $60,000 per year. However, salaries can vary depending on experience, skills, and location.

What are the working conditions for a Basin Finish Operator-TIG Welder?

Basin Finish Operator-TIG Welders typically work in a clean and well-ventilated environment. However, they may be exposed to fumes and other hazards, and must wear protective clothing and equipment.