Are you a seasoned Beam Dyer Operator seeking a new career path? Discover our professionally built Beam Dyer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

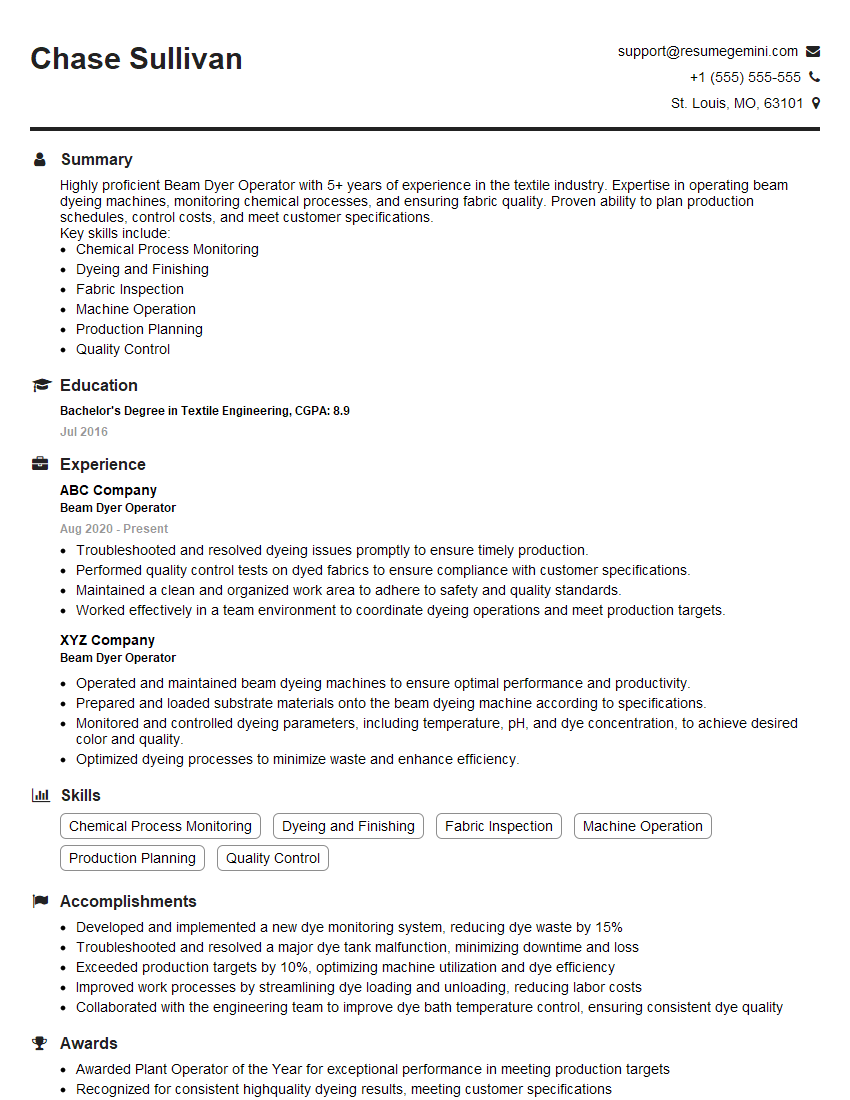

Chase Sullivan

Beam Dyer Operator

Summary

Highly proficient Beam Dyer Operator with 5+ years of experience in the textile industry. Expertise in operating beam dyeing machines, monitoring chemical processes, and ensuring fabric quality. Proven ability to plan production schedules, control costs, and meet customer specifications.

Key skills include:

- Chemical Process Monitoring

- Dyeing and Finishing

- Fabric Inspection

- Machine Operation

- Production Planning

- Quality Control

Education

Bachelor’s Degree in Textile Engineering

July 2016

Skills

- Chemical Process Monitoring

- Dyeing and Finishing

- Fabric Inspection

- Machine Operation

- Production Planning

- Quality Control

Work Experience

Beam Dyer Operator

- Troubleshooted and resolved dyeing issues promptly to ensure timely production.

- Performed quality control tests on dyed fabrics to ensure compliance with customer specifications.

- Maintained a clean and organized work area to adhere to safety and quality standards.

- Worked effectively in a team environment to coordinate dyeing operations and meet production targets.

Beam Dyer Operator

- Operated and maintained beam dyeing machines to ensure optimal performance and productivity.

- Prepared and loaded substrate materials onto the beam dyeing machine according to specifications.

- Monitored and controlled dyeing parameters, including temperature, pH, and dye concentration, to achieve desired color and quality.

- Optimized dyeing processes to minimize waste and enhance efficiency.

Accomplishments

- Developed and implemented a new dye monitoring system, reducing dye waste by 15%

- Troubleshooted and resolved a major dye tank malfunction, minimizing downtime and loss

- Exceeded production targets by 10%, optimizing machine utilization and dye efficiency

- Improved work processes by streamlining dye loading and unloading, reducing labor costs

- Collaborated with the engineering team to improve dye bath temperature control, ensuring consistent dye quality

Awards

- Awarded Plant Operator of the Year for exceptional performance in meeting production targets

- Recognized for consistent highquality dyeing results, meeting customer specifications

- Received a safety award for maintaining an accidentfree work environment

- Nominated for the Employee of the Quarter award for outstanding contributions to the team

Certificates

- AATCC Textile Colorist Certification

- Certified Textile Chemist (CTC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Beam Dyer Operator

- Highlight your technical expertise in beam dyeing, including your understanding of chemical processes and fabric properties.

- Showcase your experience in operating and maintaining beam dyeing machines.

- Emphasize your ability to produce high-quality fabric that meets customer specifications.

- Include quantifiable achievements, such as reducing production costs or improving fabric quality.

Essential Experience Highlights for a Strong Beam Dyer Operator Resume

- Operate and maintain beam dyeing machines to dye fabric according to specifications.

- Monitor chemical processes during dyeing to ensure optimal results and product quality.

- Inspect fabric before, during, and after dyeing to identify any defects or discrepancies.

- Plan production schedules, coordinate with other departments, and ensure timely delivery.

- Control production costs by optimizing chemical usage, reducing waste, and minimizing downtime.

- Conduct quality control tests to ensure fabric meets customer specifications.

- Troubleshoot and resolve machine malfunctions or production issues to minimize downtime.

Frequently Asked Questions (FAQ’s) For Beam Dyer Operator

What is the role of a Beam Dyer Operator?

A Beam Dyer Operator is responsible for operating and maintaining beam dyeing machines to dye fabric according to specifications. They monitor chemical processes, inspect fabric, plan production schedules, and ensure fabric quality meets customer standards.

What are the qualifications to become a Beam Dyer Operator?

A Beam Dyer Operator typically requires a high school diploma or equivalent, with some companies preferring candidates with a Bachelor’s Degree in Textile Engineering or a related field.

What skills are required to be a successful Beam Dyer Operator?

Successful Beam Dyer Operators possess technical expertise in beam dyeing, including an understanding of chemical processes and fabric properties. They are also proficient in operating and maintaining beam dyeing machines, inspecting fabric, planning production schedules, and ensuring fabric quality.

What are the career opportunities for a Beam Dyer Operator?

Beam Dyer Operators can advance to become Dyeing Supervisors, Production Managers, or Quality Control Managers. With additional education and experience, they may also become Textile Engineers or Research and Development Specialists.

What is the job outlook for a Beam Dyer Operator?

The job outlook for Beam Dyer Operators is expected to be stable over the next several years. The demand for skilled textile workers is driven by the growing global textile industry.

What are the benefits of working as a Beam Dyer Operator?

Beam Dyer Operators enjoy competitive salaries and benefits packages. They also have the opportunity to work in a dynamic and challenging environment, where they can contribute to the production of high-quality textiles.