Are you a seasoned Belt Operator seeking a new career path? Discover our professionally built Belt Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

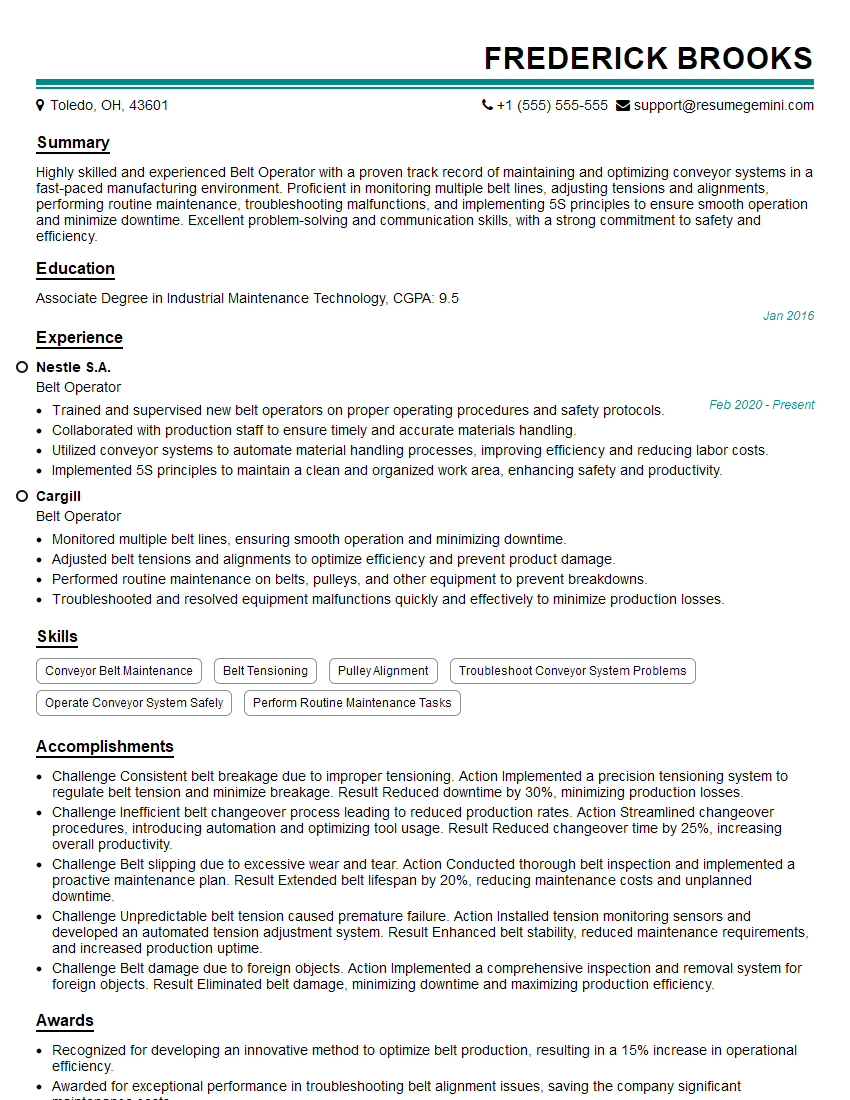

Frederick Brooks

Belt Operator

Summary

Highly skilled and experienced Belt Operator with a proven track record of maintaining and optimizing conveyor systems in a fast-paced manufacturing environment. Proficient in monitoring multiple belt lines, adjusting tensions and alignments, performing routine maintenance, troubleshooting malfunctions, and implementing 5S principles to ensure smooth operation and minimize downtime. Excellent problem-solving and communication skills, with a strong commitment to safety and efficiency.

Education

Associate Degree in Industrial Maintenance Technology

January 2016

Skills

- Conveyor Belt Maintenance

- Belt Tensioning

- Pulley Alignment

- Troubleshoot Conveyor System Problems

- Operate Conveyor System Safely

- Perform Routine Maintenance Tasks

Work Experience

Belt Operator

- Trained and supervised new belt operators on proper operating procedures and safety protocols.

- Collaborated with production staff to ensure timely and accurate materials handling.

- Utilized conveyor systems to automate material handling processes, improving efficiency and reducing labor costs.

- Implemented 5S principles to maintain a clean and organized work area, enhancing safety and productivity.

Belt Operator

- Monitored multiple belt lines, ensuring smooth operation and minimizing downtime.

- Adjusted belt tensions and alignments to optimize efficiency and prevent product damage.

- Performed routine maintenance on belts, pulleys, and other equipment to prevent breakdowns.

- Troubleshooted and resolved equipment malfunctions quickly and effectively to minimize production losses.

Accomplishments

- Challenge Consistent belt breakage due to improper tensioning. Action Implemented a precision tensioning system to regulate belt tension and minimize breakage. Result Reduced downtime by 30%, minimizing production losses.

- Challenge Inefficient belt changeover process leading to reduced production rates. Action Streamlined changeover procedures, introducing automation and optimizing tool usage. Result Reduced changeover time by 25%, increasing overall productivity.

- Challenge Belt slipping due to excessive wear and tear. Action Conducted thorough belt inspection and implemented a proactive maintenance plan. Result Extended belt lifespan by 20%, reducing maintenance costs and unplanned downtime.

- Challenge Unpredictable belt tension caused premature failure. Action Installed tension monitoring sensors and developed an automated tension adjustment system. Result Enhanced belt stability, reduced maintenance requirements, and increased production uptime.

- Challenge Belt damage due to foreign objects. Action Implemented a comprehensive inspection and removal system for foreign objects. Result Eliminated belt damage, minimizing downtime and maximizing production efficiency.

Awards

- Recognized for developing an innovative method to optimize belt production, resulting in a 15% increase in operational efficiency.

- Awarded for exceptional performance in troubleshooting belt alignment issues, saving the company significant maintenance costs.

- Recognized for outstanding safety compliance, ensuring zero incidents in a highrisk environment.

- Awarded for exceptional proficiency in conveyor belt splicing techniques, ensuring seamless and durable belt connections.

Certificates

- Certified Belt Operator (CBO)

- Maintenance and Reliability Technician (MRT) Certification

- Certified Maintenance Manager (CMM)

- Occupational Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Belt Operator

- Highlight your experience and skills in belt maintenance, conveyor system operation, and troubleshooting.

- Quantify your achievements whenever possible, using specific metrics to demonstrate your impact on efficiency and productivity.

- Tailor your resume to each job posting, emphasizing the skills and experience that are most relevant to the specific role you are applying for.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Belt Operator Resume

- Monitored multiple belt lines, ensuring smooth operation and minimizing downtime.

- Adjusted belt tensions and alignments to optimize efficiency and prevent product damage.

- Performed routine maintenance on belts, pulleys, and other equipment to prevent breakdowns.

- Troubleshooted and resolved equipment malfunctions quickly and effectively to minimize production losses.

- Trained and supervised new belt operators on proper operating procedures and safety protocols.

Frequently Asked Questions (FAQ’s) For Belt Operator

What are the key responsibilities of a Belt Operator?

The key responsibilities of a Belt Operator include monitoring and maintaining conveyor systems, adjusting tensions and alignments, performing routine maintenance, troubleshooting malfunctions, and ensuring that the equipment is operating safely and efficiently.

What skills are required to be a successful Belt Operator?

Successful Belt Operators typically have a strong understanding of conveyor systems, including their components and operation. They are also proficient in troubleshooting and repairing equipment, and have a strong commitment to safety.

What are the career prospects for Belt Operators?

Belt Operators with experience and a proven track record can advance to supervisory or management roles within the manufacturing industry. They may also be able to specialize in a particular area, such as conveyor system design or maintenance.

What is the work environment like for Belt Operators?

Belt Operators typically work in industrial settings, such as factories or warehouses. They may be exposed to noise, dust, and other hazards, so it is important to wear appropriate safety gear and follow all safety protocols.

How can I become a Belt Operator?

There are several ways to become a Belt Operator. Some employers may require a high school diploma or equivalent, while others may prefer candidates with an associate degree in industrial maintenance technology or a related field. Prior experience in a manufacturing or industrial setting is also beneficial.

How much do Belt Operators make?

The salary of a Belt Operator can vary depending on their experience, location, and employer. According to Salary.com, the average salary for a Belt Operator in the United States is around $35,000 per year.

What are the benefits of working as a Belt Operator?

Working as a Belt Operator can offer a number of benefits, including a stable income, opportunities for advancement, and the chance to work with a team of skilled professionals.