Are you a seasoned Belting and Webbing Inspector seeking a new career path? Discover our professionally built Belting and Webbing Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

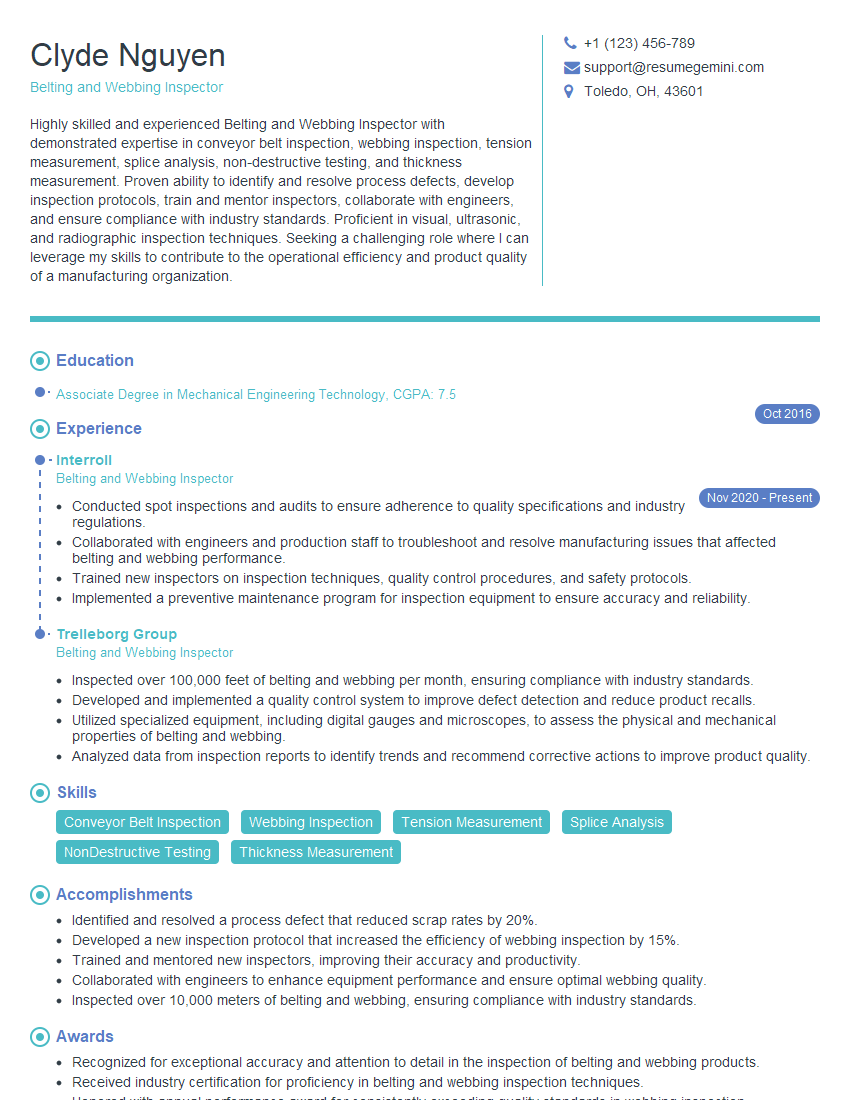

Clyde Nguyen

Belting and Webbing Inspector

Summary

Highly skilled and experienced Belting and Webbing Inspector with demonstrated expertise in conveyor belt inspection, webbing inspection, tension measurement, splice analysis, non-destructive testing, and thickness measurement. Proven ability to identify and resolve process defects, develop inspection protocols, train and mentor inspectors, collaborate with engineers, and ensure compliance with industry standards. Proficient in visual, ultrasonic, and radiographic inspection techniques. Seeking a challenging role where I can leverage my skills to contribute to the operational efficiency and product quality of a manufacturing organization.

Education

Associate Degree in Mechanical Engineering Technology

October 2016

Skills

- Conveyor Belt Inspection

- Webbing Inspection

- Tension Measurement

- Splice Analysis

- NonDestructive Testing

- Thickness Measurement

Work Experience

Belting and Webbing Inspector

- Conducted spot inspections and audits to ensure adherence to quality specifications and industry regulations.

- Collaborated with engineers and production staff to troubleshoot and resolve manufacturing issues that affected belting and webbing performance.

- Trained new inspectors on inspection techniques, quality control procedures, and safety protocols.

- Implemented a preventive maintenance program for inspection equipment to ensure accuracy and reliability.

Belting and Webbing Inspector

- Inspected over 100,000 feet of belting and webbing per month, ensuring compliance with industry standards.

- Developed and implemented a quality control system to improve defect detection and reduce product recalls.

- Utilized specialized equipment, including digital gauges and microscopes, to assess the physical and mechanical properties of belting and webbing.

- Analyzed data from inspection reports to identify trends and recommend corrective actions to improve product quality.

Accomplishments

- Identified and resolved a process defect that reduced scrap rates by 20%.

- Developed a new inspection protocol that increased the efficiency of webbing inspection by 15%.

- Trained and mentored new inspectors, improving their accuracy and productivity.

- Collaborated with engineers to enhance equipment performance and ensure optimal webbing quality.

- Inspected over 10,000 meters of belting and webbing, ensuring compliance with industry standards.

Awards

- Recognized for exceptional accuracy and attention to detail in the inspection of belting and webbing products.

- Received industry certification for proficiency in belting and webbing inspection techniques.

- Honored with annual performance award for consistently exceeding quality standards in webbing inspection.

Certificates

- Certified Belt Inspector (CBI)

- Certified Webbing Inspector (CWI)

- Certified Splice Technician (CST)

- Certified NonDestructive Testing (NDT) Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Belting and Webbing Inspector

- Highlight your experience in conveyor belt and webbing inspection, emphasizing the specific techniques you are proficient in.

- Quantify your accomplishments whenever possible, using metrics such as percentage of defects reduced or efficiency gains achieved.

- Showcase your knowledge of industry standards and regulations related to belting and webbing inspection.

- Demonstrate your ability to work independently and as part of a team, and highlight your problem-solving and analytical skills.

Essential Experience Highlights for a Strong Belting and Webbing Inspector Resume

- Inspect conveyor belts and webbing for defects, wear, and damage.

- Measure belt tension and ensure it is within specified limits.

- Analyze splice joints for strength and integrity.

- Perform non-destructive testing to identify hidden defects.

- Measure belt thickness and width to ensure compliance with specifications.

- Maintain accurate inspection records and report any irregularities.

- Collaborate with engineers to improve equipment performance and webbing quality.

Frequently Asked Questions (FAQ’s) For Belting and Webbing Inspector

What are the key skills required for a Belting and Webbing Inspector?

Strong knowledge of conveyor belt and webbing materials and construction, proficiency in visual, ultrasonic, and radiographic inspection techniques, ability to measure belt tension and thickness, and familiarity with industry standards and regulations.

What are the career prospects for Belting and Webbing Inspectors?

Belting and Webbing Inspectors can advance to roles such as Quality Control Manager, Production Supervisor, or Maintenance Manager. With experience and additional training, they can also specialize in specific areas such as non-destructive testing or equipment maintenance.

What are the typical working conditions for Belting and Webbing Inspectors?

Belting and Webbing Inspectors typically work in manufacturing facilities, warehouses, or other industrial settings. They may work in a team or independently, and may be required to work in confined spaces or at heights.

What is the average salary for a Belting and Webbing Inspector?

The average salary for a Belting and Webbing Inspector in the United States is around $50,000 per year, according to Indeed. Salaries may vary depending on experience, location, and industry.

What are the educational requirements for a Belting and Webbing Inspector?

Most Belting and Webbing Inspectors have an associate degree in mechanical engineering technology or a related field, or equivalent experience. Some employers may also require certification from a recognized organization such as the American Society for Nondestructive Testing (ASNT).

What are the certification options available for Belting and Webbing Inspectors?

There are several certifications available for Belting and Webbing Inspectors, including Level II certification in Ultrasonic Testing (UT) and Level II certification in Radiographic Testing (RT) from ASNT. These certifications demonstrate proficiency in specific inspection techniques and enhance credibility in the field.