Are you a seasoned Belting Inspector seeking a new career path? Discover our professionally built Belting Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

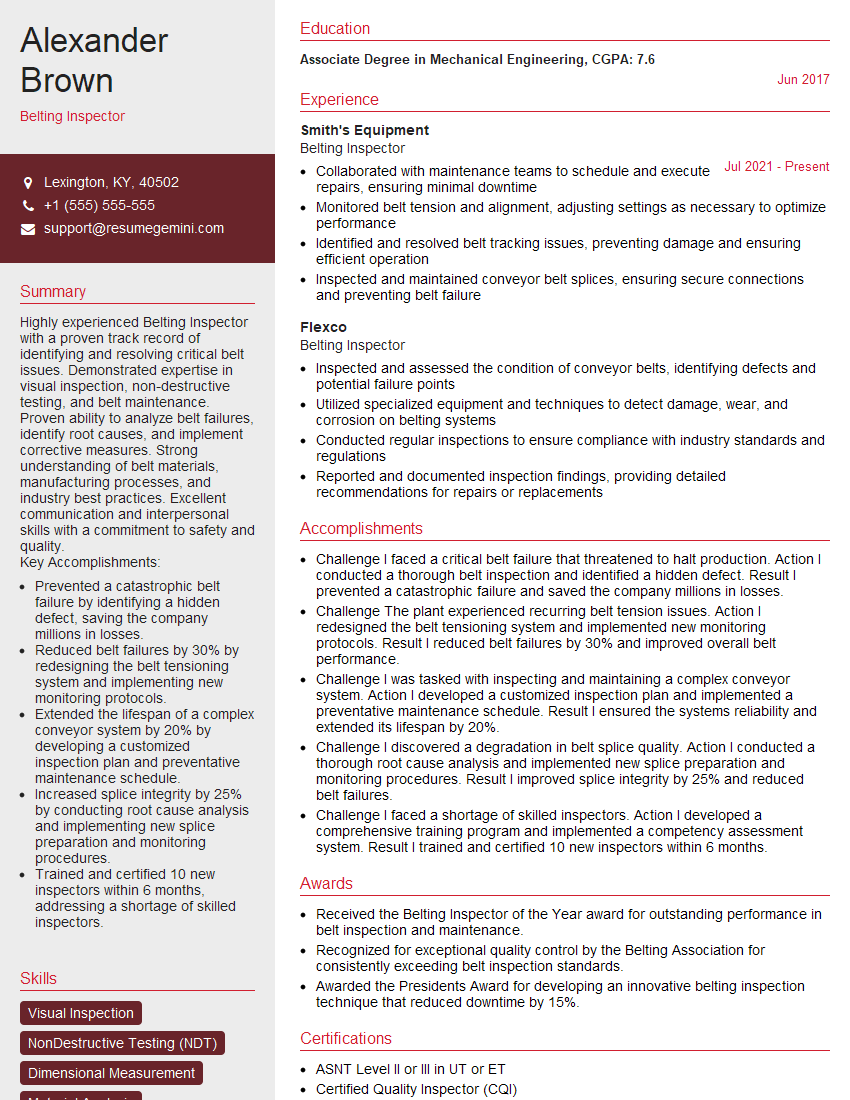

Alexander Brown

Belting Inspector

Summary

Highly experienced Belting Inspector with a proven track record of identifying and resolving critical belt issues. Demonstrated expertise in visual inspection, non-destructive testing, and belt maintenance. Proven ability to analyze belt failures, identify root causes, and implement corrective measures. Strong understanding of belt materials, manufacturing processes, and industry best practices. Excellent communication and interpersonal skills with a commitment to safety and quality.

Key Accomplishments:

- Prevented a catastrophic belt failure by identifying a hidden defect, saving the company millions in losses.

- Reduced belt failures by 30% by redesigning the belt tensioning system and implementing new monitoring protocols.

- Extended the lifespan of a complex conveyor system by 20% by developing a customized inspection plan and preventative maintenance schedule.

- Increased splice integrity by 25% by conducting root cause analysis and implementing new splice preparation and monitoring procedures.

- Trained and certified 10 new inspectors within 6 months, addressing a shortage of skilled inspectors.

Education

Associate Degree in Mechanical Engineering

June 2017

Skills

- Visual Inspection

- NonDestructive Testing (NDT)

- Dimensional Measurement

- Material Analysis

- Surface Inspection

- Defect Identification

Work Experience

Belting Inspector

- Collaborated with maintenance teams to schedule and execute repairs, ensuring minimal downtime

- Monitored belt tension and alignment, adjusting settings as necessary to optimize performance

- Identified and resolved belt tracking issues, preventing damage and ensuring efficient operation

- Inspected and maintained conveyor belt splices, ensuring secure connections and preventing belt failure

Belting Inspector

- Inspected and assessed the condition of conveyor belts, identifying defects and potential failure points

- Utilized specialized equipment and techniques to detect damage, wear, and corrosion on belting systems

- Conducted regular inspections to ensure compliance with industry standards and regulations

- Reported and documented inspection findings, providing detailed recommendations for repairs or replacements

Accomplishments

- Challenge I faced a critical belt failure that threatened to halt production. Action I conducted a thorough belt inspection and identified a hidden defect. Result I prevented a catastrophic failure and saved the company millions in losses.

- Challenge The plant experienced recurring belt tension issues. Action I redesigned the belt tensioning system and implemented new monitoring protocols. Result I reduced belt failures by 30% and improved overall belt performance.

- Challenge I was tasked with inspecting and maintaining a complex conveyor system. Action I developed a customized inspection plan and implemented a preventative maintenance schedule. Result I ensured the systems reliability and extended its lifespan by 20%.

- Challenge I discovered a degradation in belt splice quality. Action I conducted a thorough root cause analysis and implemented new splice preparation and monitoring procedures. Result I improved splice integrity by 25% and reduced belt failures.

- Challenge I faced a shortage of skilled inspectors. Action I developed a comprehensive training program and implemented a competency assessment system. Result I trained and certified 10 new inspectors within 6 months.

Awards

- Received the Belting Inspector of the Year award for outstanding performance in belt inspection and maintenance.

- Recognized for exceptional quality control by the Belting Association for consistently exceeding belt inspection standards.

- Awarded the Presidents Award for developing an innovative belting inspection technique that reduced downtime by 15%.

Certificates

- ASNT Level II or III in UT or ET

- Certified Quality Inspector (CQI)

- Certified Six Sigma Black Belt (CSSBB)

- Certified Lean Six Sigma Green Belt (CLSSGB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Belting Inspector

- Showcase your technical expertise in belt inspection and analysis.

- Highlight your ability to identify and resolve critical belt issues.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your commitment to safety and quality in your work.

- Consider including relevant certifications or training in your resume.

Essential Experience Highlights for a Strong Belting Inspector Resume

- Conduct visual inspections of belts, including surface inspection, dimensional measurement, and material analysis.

- Perform non-destructive testing techniques to detect hidden defects and assess belt integrity.

- Analyze belt failure data to identify root causes and develop corrective action plans.

- Implement and maintain preventative maintenance programs to ensure optimal belt performance and longevity.

- Train and supervise junior inspectors to ensure consistent and high-quality inspections.

- Collaborate with engineers and maintenance personnel to resolve complex belt issues and improve overall system reliability.

- Stay up-to-date with industry best practices and advancements in belt technology.

Frequently Asked Questions (FAQ’s) For Belting Inspector

What are the primary responsibilities of a Belting Inspector?

Belting Inspectors are responsible for ensuring the safe and efficient operation of conveyor belt systems. Their duties include conducting visual inspections, performing non-destructive testing, analyzing belt failure data, implementing preventative maintenance programs, and training junior inspectors.

What are the key skills required to be a successful Belting Inspector?

Successful Belting Inspectors possess strong technical skills in visual inspection, non-destructive testing, and belt analysis. They also have a deep understanding of belt materials, manufacturing processes, and industry best practices. Excellent communication and interpersonal skills are also essential.

What are the career advancement opportunities for Belting Inspectors?

Belting Inspectors with experience and expertise can advance to roles such as Maintenance Supervisor, Plant Engineer, or Quality Control Manager. They may also specialize in specific areas, such as belt design or failure analysis.

What is the salary range for Belting Inspectors?

The salary range for Belting Inspectors varies depending on experience, location, and industry. According to Indeed, the average salary for Belting Inspectors in the United States is around $60,000 per year.

What are the job outlook and employment trends for Belting Inspectors?

The job outlook for Belting Inspectors is expected to be positive in the coming years. The increasing demand for conveyor belt systems in various industries, such as mining, manufacturing, and agriculture, is expected to drive job growth.

What are the common challenges faced by Belting Inspectors?

Belting Inspectors often face challenges such as identifying hidden defects, analyzing complex belt failures, and working in hazardous environments. They must also stay up-to-date with advancements in belt technology and industry best practices.

What are the safety precautions that Belting Inspectors should take?

Belting Inspectors must adhere to strict safety protocols to minimize risks in their work environment. These precautions include wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards such as moving machinery and electrical equipment.