Are you a seasoned Bending Machine Set Up Operator seeking a new career path? Discover our professionally built Bending Machine Set Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

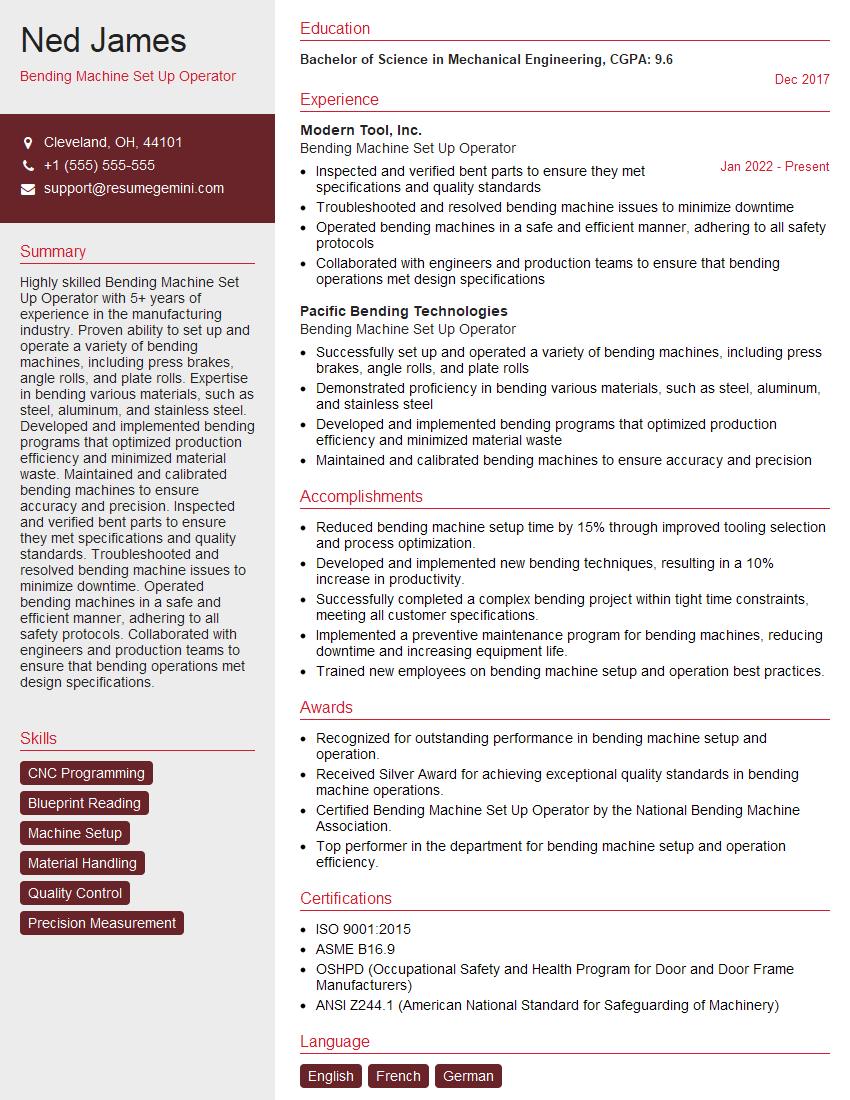

Ned James

Bending Machine Set Up Operator

Summary

Highly skilled Bending Machine Set Up Operator with 5+ years of experience in the manufacturing industry. Proven ability to set up and operate a variety of bending machines, including press brakes, angle rolls, and plate rolls. Expertise in bending various materials, such as steel, aluminum, and stainless steel. Developed and implemented bending programs that optimized production efficiency and minimized material waste. Maintained and calibrated bending machines to ensure accuracy and precision. Inspected and verified bent parts to ensure they met specifications and quality standards. Troubleshooted and resolved bending machine issues to minimize downtime. Operated bending machines in a safe and efficient manner, adhering to all safety protocols. Collaborated with engineers and production teams to ensure that bending operations met design specifications.

Education

Bachelor of Science in Mechanical Engineering

December 2017

Skills

- CNC Programming

- Blueprint Reading

- Machine Setup

- Material Handling

- Quality Control

- Precision Measurement

Work Experience

Bending Machine Set Up Operator

- Inspected and verified bent parts to ensure they met specifications and quality standards

- Troubleshooted and resolved bending machine issues to minimize downtime

- Operated bending machines in a safe and efficient manner, adhering to all safety protocols

- Collaborated with engineers and production teams to ensure that bending operations met design specifications

Bending Machine Set Up Operator

- Successfully set up and operated a variety of bending machines, including press brakes, angle rolls, and plate rolls

- Demonstrated proficiency in bending various materials, such as steel, aluminum, and stainless steel

- Developed and implemented bending programs that optimized production efficiency and minimized material waste

- Maintained and calibrated bending machines to ensure accuracy and precision

Accomplishments

- Reduced bending machine setup time by 15% through improved tooling selection and process optimization.

- Developed and implemented new bending techniques, resulting in a 10% increase in productivity.

- Successfully completed a complex bending project within tight time constraints, meeting all customer specifications.

- Implemented a preventive maintenance program for bending machines, reducing downtime and increasing equipment life.

- Trained new employees on bending machine setup and operation best practices.

Awards

- Recognized for outstanding performance in bending machine setup and operation.

- Received Silver Award for achieving exceptional quality standards in bending machine operations.

- Certified Bending Machine Set Up Operator by the National Bending Machine Association.

- Top performer in the department for bending machine setup and operation efficiency.

Certificates

- ISO 9001:2015

- ASME B16.9

- OSHPD (Occupational Safety and Health Program for Door and Door Frame Manufacturers)

- ANSI Z244.1 (American National Standard for Safeguarding of Machinery)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bending Machine Set Up Operator

- Highlight your skills and experience in setting up and operating bending machines.

- Showcase your knowledge of bending programs and how you have used them to improve production efficiency.

- Emphasize your ability to maintain and calibrate bending machines to ensure accuracy and precision.

- Include examples of how you have troubleshooted and resolved bending machine issues.

- Provide evidence of your commitment to safety and quality control.

Essential Experience Highlights for a Strong Bending Machine Set Up Operator Resume

- Set up and operate bending machines, including press brakes, angle rolls, and plate rolls

- Develop and implement bending programs to optimize production efficiency and minimize material waste

- Maintain and calibrate bending machines to ensure accuracy and precision

- Inspect and verify bent parts to ensure they meet specifications and quality standards

- Troubleshoot and resolve bending machine issues to minimize downtime

- Operate bending machines in a safe and efficient manner, adhering to all safety protocols

- Collaborate with engineers and production teams to ensure that bending operations met design specifications

Frequently Asked Questions (FAQ’s) For Bending Machine Set Up Operator

What are the essential skills required for a Bending Machine Set Up Operator?

Essential skills for a Bending Machine Set Up Operator include the ability to set up and operate bending machines, develop and implement bending programs, maintain and calibrate bending machines, inspect and verify bent parts, troubleshoot and resolve bending machine issues, and operate bending machines in a safe and efficient manner.

What is the average salary for a Bending Machine Set Up Operator?

The average salary for a Bending Machine Set Up Operator in the United States is around $45,000 per year.

What are the career prospects for a Bending Machine Set Up Operator?

Bending Machine Set Up Operators can advance to positions such as Supervisor, Production Manager, or Quality Control Manager. Some may also choose to start their own businesses.

What is the work environment for a Bending Machine Set Up Operator?

Bending Machine Set Up Operators typically work in a manufacturing environment. They may work indoors or outdoors, and may be exposed to noise, dust, and fumes. They may also be required to lift heavy objects.

What are the educational requirements for a Bending Machine Set Up Operator?

Most Bending Machine Set Up Operators have a high school diploma or equivalent. Some employers may prefer candidates with a technical degree or certification in a related field, such as manufacturing or engineering.

What are the safety precautions that a Bending Machine Set Up Operator should take?

Bending Machine Set Up Operators should always wear appropriate safety gear, such as safety glasses, gloves, and earplugs. They should also be aware of the potential hazards associated with operating bending machines, such as pinch points, sharp edges, and moving parts.

What are the key qualities of a successful Bending Machine Set Up Operator?

Successful Bending Machine Set Up Operators are typically detail-oriented, have good problem-solving skills, and are able to work independently. They are also able to work safely and efficiently in a fast-paced environment.

What are some of the challenges that a Bending Machine Set Up Operator may face?

Bending Machine Set Up Operators may face challenges such as working with difficult materials, meeting tight deadlines, and working in a noisy and dusty environment. They may also need to be able to troubleshoot and repair bending machines.