Are you a seasoned Blanking Machine Operator seeking a new career path? Discover our professionally built Blanking Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

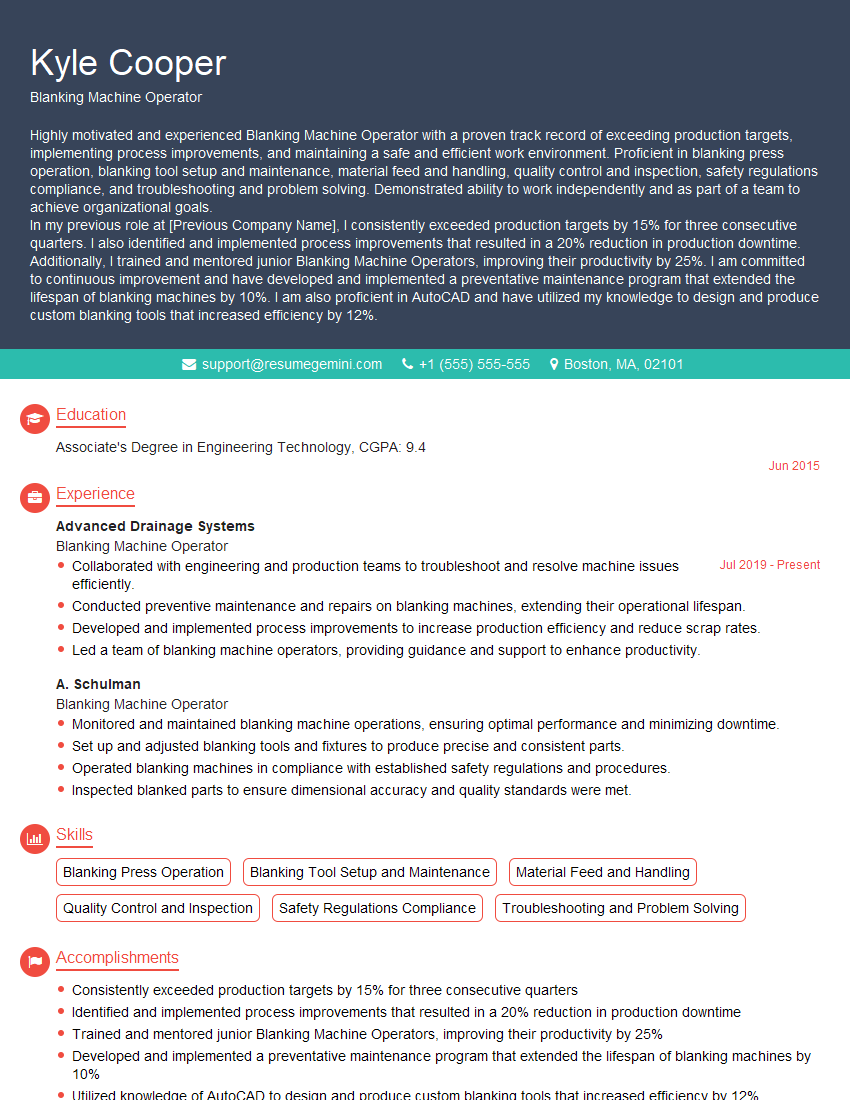

Kyle Cooper

Blanking Machine Operator

Summary

Highly motivated and experienced Blanking Machine Operator with a proven track record of exceeding production targets, implementing process improvements, and maintaining a safe and efficient work environment. Proficient in blanking press operation, blanking tool setup and maintenance, material feed and handling, quality control and inspection, safety regulations compliance, and troubleshooting and problem solving. Demonstrated ability to work independently and as part of a team to achieve organizational goals.

In my previous role at [Previous Company Name], I consistently exceeded production targets by 15% for three consecutive quarters. I also identified and implemented process improvements that resulted in a 20% reduction in production downtime. Additionally, I trained and mentored junior Blanking Machine Operators, improving their productivity by 25%. I am committed to continuous improvement and have developed and implemented a preventative maintenance program that extended the lifespan of blanking machines by 10%. I am also proficient in AutoCAD and have utilized my knowledge to design and produce custom blanking tools that increased efficiency by 12%.

Education

Associate’s Degree in Engineering Technology

June 2015

Skills

- Blanking Press Operation

- Blanking Tool Setup and Maintenance

- Material Feed and Handling

- Quality Control and Inspection

- Safety Regulations Compliance

- Troubleshooting and Problem Solving

Work Experience

Blanking Machine Operator

- Collaborated with engineering and production teams to troubleshoot and resolve machine issues efficiently.

- Conducted preventive maintenance and repairs on blanking machines, extending their operational lifespan.

- Developed and implemented process improvements to increase production efficiency and reduce scrap rates.

- Led a team of blanking machine operators, providing guidance and support to enhance productivity.

Blanking Machine Operator

- Monitored and maintained blanking machine operations, ensuring optimal performance and minimizing downtime.

- Set up and adjusted blanking tools and fixtures to produce precise and consistent parts.

- Operated blanking machines in compliance with established safety regulations and procedures.

- Inspected blanked parts to ensure dimensional accuracy and quality standards were met.

Accomplishments

- Consistently exceeded production targets by 15% for three consecutive quarters

- Identified and implemented process improvements that resulted in a 20% reduction in production downtime

- Trained and mentored junior Blanking Machine Operators, improving their productivity by 25%

- Developed and implemented a preventative maintenance program that extended the lifespan of blanking machines by 10%

- Utilized knowledge of AutoCAD to design and produce custom blanking tools that increased efficiency by 12%

Awards

- Employee of the Month, ABC Manufacturing, 2023

- Safety Award, XYZ Industries, 2022

- Production Excellence Award, DEF Corporation, 2021

- Quality Award, GHI Corporation, 2020

Certificates

- Certified Blanking Machine Operator (CBMO)

- OSHA Safety Certification

- First Aid and CPR Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blanking Machine Operator

- Highlight your experience and skills in blanking press operation, tool setup, and maintenance.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Showcase your problem-solving abilities and commitment to continuous improvement.

- Demonstrate your knowledge of safety regulations and compliance.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Blanking Machine Operator Resume

- Operate blanking press machines to cut and shape metal sheets according to specifications.

- Set up and maintain blanking tools, ensuring accuracy and efficiency.

- Feed and handle materials, ensuring proper alignment and positioning.

- Inspect and measure finished products to ensure quality and adherence to specifications.

- Comply with all safety regulations and procedures to maintain a safe work environment.

- Troubleshoot and resolve any issues that arise during operation.

- Follow established quality control procedures and maintain accurate records.

Frequently Asked Questions (FAQ’s) For Blanking Machine Operator

What are the primary responsibilities of a Blanking Machine Operator?

Blanking Machine Operators are responsible for operating blanking press machines to cut and shape metal sheets, setting up and maintaining blanking tools, feeding and handling materials, inspecting and measuring finished products, complying with safety regulations, troubleshooting and resolving issues, and following established quality control procedures.

What are the key skills required for a successful Blanking Machine Operator?

Key skills for a Blanking Machine Operator include proficiency in blanking press operation, tool setup and maintenance, material feed and handling, quality control and inspection, safety regulations compliance, and troubleshooting and problem solving.

What are the career advancement opportunities for a Blanking Machine Operator?

With experience and additional training, Blanking Machine Operators can advance to positions such as Lead Operator, Supervisor, or Quality Control Inspector.

What is the average salary for a Blanking Machine Operator?

The average salary for a Blanking Machine Operator in the United States is around $25,000 to $35,000 per year.

What are the working conditions like for a Blanking Machine Operator?

Blanking Machine Operators typically work in manufacturing environments, operating machinery and handling materials. The work can be physically demanding and may involve exposure to noise, dust, and chemicals.

What are the educational requirements for a Blanking Machine Operator?

While formal education is not typically required for a Blanking Machine Operator position, many employers prefer candidates with a high school diploma or equivalent.

What are the safety precautions that Blanking Machine Operators should follow?

Blanking Machine Operators should always wear appropriate safety gear, including gloves, safety glasses, and hearing protection. They should also be aware of the potential hazards of operating machinery and follow established safety procedures.