Are you a seasoned Blanking Press Operator seeking a new career path? Discover our professionally built Blanking Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

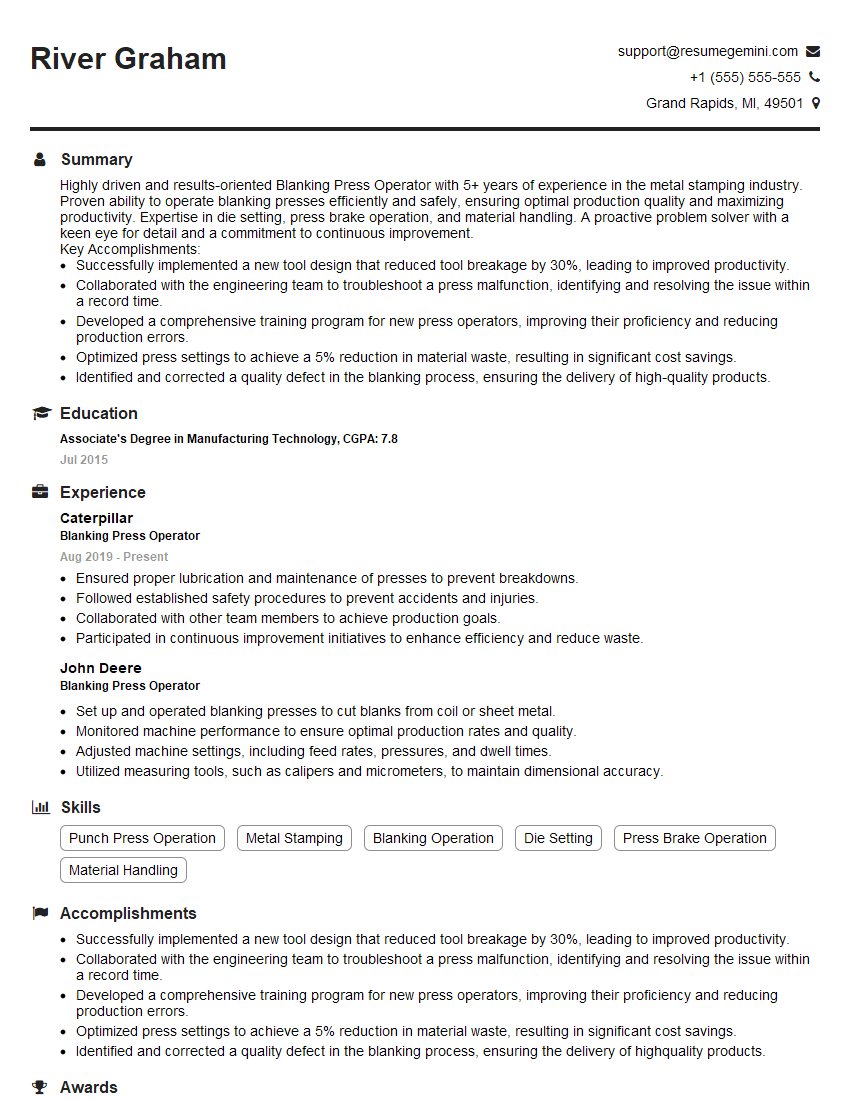

River Graham

Blanking Press Operator

Summary

Highly driven and results-oriented Blanking Press Operator with 5+ years of experience in the metal stamping industry. Proven ability to operate blanking presses efficiently and safely, ensuring optimal production quality and maximizing productivity. Expertise in die setting, press brake operation, and material handling. A proactive problem solver with a keen eye for detail and a commitment to continuous improvement.

Key Accomplishments:

- Successfully implemented a new tool design that reduced tool breakage by 30%, leading to improved productivity.

- Collaborated with the engineering team to troubleshoot a press malfunction, identifying and resolving the issue within a record time.

- Developed a comprehensive training program for new press operators, improving their proficiency and reducing production errors.

- Optimized press settings to achieve a 5% reduction in material waste, resulting in significant cost savings.

- Identified and corrected a quality defect in the blanking process, ensuring the delivery of high-quality products.

Education

Associate’s Degree in Manufacturing Technology

July 2015

Skills

- Punch Press Operation

- Metal Stamping

- Blanking Operation

- Die Setting

- Press Brake Operation

- Material Handling

Work Experience

Blanking Press Operator

- Ensured proper lubrication and maintenance of presses to prevent breakdowns.

- Followed established safety procedures to prevent accidents and injuries.

- Collaborated with other team members to achieve production goals.

- Participated in continuous improvement initiatives to enhance efficiency and reduce waste.

Blanking Press Operator

- Set up and operated blanking presses to cut blanks from coil or sheet metal.

- Monitored machine performance to ensure optimal production rates and quality.

- Adjusted machine settings, including feed rates, pressures, and dwell times.

- Utilized measuring tools, such as calipers and micrometers, to maintain dimensional accuracy.

Accomplishments

- Successfully implemented a new tool design that reduced tool breakage by 30%, leading to improved productivity.

- Collaborated with the engineering team to troubleshoot a press malfunction, identifying and resolving the issue within a record time.

- Developed a comprehensive training program for new press operators, improving their proficiency and reducing production errors.

- Optimized press settings to achieve a 5% reduction in material waste, resulting in significant cost savings.

- Identified and corrected a quality defect in the blanking process, ensuring the delivery of highquality products.

Awards

- Received the Outstanding Production Award for consistently exceeding production targets by 20%.

- Honored with the Safety Excellence Award for maintaining an impeccable safety record over a twoyear period.

- Recognized as the Top Performer for achieving the highest production output among all Blanking Press Operators.

- Honored with the Employee of the Month award for exceptional performance and dedication.

Certificates

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

- National Institute for Metalworking Skills (NIMS) Certification

- American Society of Mechanical Engineers (ASME) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blanking Press Operator

- Highlight your experience operating blanking presses and any relevant certifications you may have.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on productivity and quality.

- Showcase your problem-solving and analytical skills by describing how you have identified and resolved issues in your previous roles.

- Emphasize your attention to detail and commitment to safety by providing examples of how you have ensured the accuracy and safety of your work.

Essential Experience Highlights for a Strong Blanking Press Operator Resume

- Operate blanking presses to cut and shape metal sheets according to specifications.

- Set up and adjust dies and tooling to ensure proper operation.

- Monitor press operation and make adjustments as needed to maintain optimal production quality.

- Inspect finished products to ensure they meet specifications and quality standards.

- Perform preventive maintenance on presses and related equipment to minimize downtime.

Frequently Asked Questions (FAQ’s) For Blanking Press Operator

What is the primary role of a Blanking Press Operator?

The primary role of a Blanking Press Operator is to safely and efficiently operate blanking presses to cut and shape metal sheets according to specified dimensions and tolerances.

What qualifications are typically required to become a Blanking Press Operator?

Typically, a high school diploma or equivalent is required, along with specific training and experience in operating blanking presses and related equipment.

What are some of the key skills and abilities required for success as a Blanking Press Operator?

Some of the key skills and abilities required for success as a Blanking Press Operator include attention to detail, hand-eye coordination, mechanical aptitude, and the ability to work independently and as part of a team.

What are the career prospects for Blanking Press Operators?

Blanking Press Operators can advance their careers by gaining experience and developing specialized skills. They may also move into supervisory or management roles.

What is the average salary for Blanking Press Operators?

The average salary for Blanking Press Operators varies depending on experience, location, and industry. According to Indeed, the average salary for Blanking Press Operators in the United States is around $25 per hour.

What are the safety precautions that Blanking Press Operators must follow?

Blanking Press Operators must follow strict safety precautions to minimize the risk of accidents. These precautions include wearing appropriate safety gear, being aware of the location of emergency stop buttons, and following proper operating procedures.