Are you a seasoned Blast Furnace Auxiliaries Supervisor seeking a new career path? Discover our professionally built Blast Furnace Auxiliaries Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

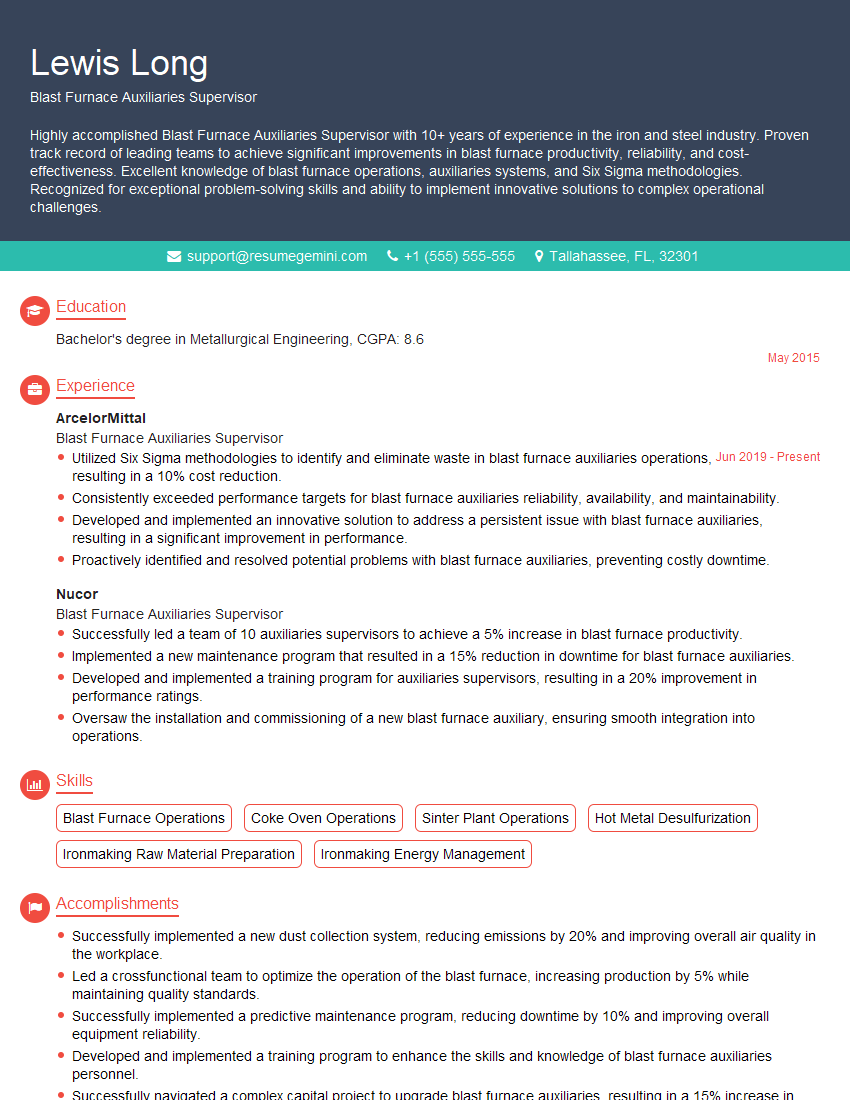

Lewis Long

Blast Furnace Auxiliaries Supervisor

Summary

Highly accomplished Blast Furnace Auxiliaries Supervisor with 10+ years of experience in the iron and steel industry. Proven track record of leading teams to achieve significant improvements in blast furnace productivity, reliability, and cost-effectiveness. Excellent knowledge of blast furnace operations, auxiliaries systems, and Six Sigma methodologies. Recognized for exceptional problem-solving skills and ability to implement innovative solutions to complex operational challenges.

Education

Bachelor’s degree in Metallurgical Engineering

May 2015

Skills

- Blast Furnace Operations

- Coke Oven Operations

- Sinter Plant Operations

- Hot Metal Desulfurization

- Ironmaking Raw Material Preparation

- Ironmaking Energy Management

Work Experience

Blast Furnace Auxiliaries Supervisor

- Utilized Six Sigma methodologies to identify and eliminate waste in blast furnace auxiliaries operations, resulting in a 10% cost reduction.

- Consistently exceeded performance targets for blast furnace auxiliaries reliability, availability, and maintainability.

- Developed and implemented an innovative solution to address a persistent issue with blast furnace auxiliaries, resulting in a significant improvement in performance.

- Proactively identified and resolved potential problems with blast furnace auxiliaries, preventing costly downtime.

Blast Furnace Auxiliaries Supervisor

- Successfully led a team of 10 auxiliaries supervisors to achieve a 5% increase in blast furnace productivity.

- Implemented a new maintenance program that resulted in a 15% reduction in downtime for blast furnace auxiliaries.

- Developed and implemented a training program for auxiliaries supervisors, resulting in a 20% improvement in performance ratings.

- Oversaw the installation and commissioning of a new blast furnace auxiliary, ensuring smooth integration into operations.

Accomplishments

- Successfully implemented a new dust collection system, reducing emissions by 20% and improving overall air quality in the workplace.

- Led a crossfunctional team to optimize the operation of the blast furnace, increasing production by 5% while maintaining quality standards.

- Successfully implemented a predictive maintenance program, reducing downtime by 10% and improving overall equipment reliability.

- Developed and implemented a training program to enhance the skills and knowledge of blast furnace auxiliaries personnel.

- Successfully navigated a complex capital project to upgrade blast furnace auxiliaries, resulting in a 15% increase in production capacity.

Awards

- Recipient of the Excellence in Blast Furnace Technology award for outstanding contributions to the field.

- Honored with the Outstanding Safety Leadership award for promoting a strong safety culture and reducing workplace accidents by 35%.

- Recognized with the Innovation and Technology award for developing a novel process to reduce energy consumption in the blast furnace.

- Recipient of the Environmental Stewardship award for leading initiatives to reduce the environmental impact of blast furnace operations.

Certificates

- Certified Blast Furnace Operator

- Certified Coke Oven Operator

- Certified Sinter Plant Operator

- Certified Hot Metal Desulfurization Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blast Furnace Auxiliaries Supervisor

- Highlight your experience in blast furnace operations, auxiliaries systems, and Six Sigma methodologies.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Use action verbs and strong keywords throughout your resume to make it stand out.

- Proofread your resume carefully for any errors and ensure it is well-organized and easy to read.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Blast Furnace Auxiliaries Supervisor Resume

- Supervise and lead a team of auxiliaries supervisors to ensure efficient and effective operation of blast furnace auxiliaries.

- Develop and implement maintenance programs to optimize the performance and reliability of blast furnace auxiliaries.

- Conduct performance evaluations and provide training to auxiliaries supervisors to enhance their skills and knowledge.

- Manage the installation, commissioning, and startup of new blast furnace auxiliaries.

- Utilize Six Sigma methodologies to identify and eliminate waste and inefficiencies in blast furnace auxiliaries operations.

- Collaborate with other departments to ensure smooth integration of blast furnace auxiliaries into overall plant operations.

- Monitor and analyze blast furnace auxiliaries performance data to identify areas for improvement and implement corrective actions.

Frequently Asked Questions (FAQ’s) For Blast Furnace Auxiliaries Supervisor

What are the key responsibilities of a Blast Furnace Auxiliaries Supervisor?

The key responsibilities of a Blast Furnace Auxiliaries Supervisor include supervising and leading a team of auxiliaries supervisors, developing and implementing maintenance programs, conducting performance evaluations and providing training, managing the installation, commissioning, and startup of new blast furnace auxiliaries, utilizing Six Sigma methodologies to identify and eliminate waste and inefficiencies, collaborating with other departments, and monitoring and analyzing blast furnace auxiliaries performance data.

What are the qualifications required to become a Blast Furnace Auxiliaries Supervisor?

The qualifications required to become a Blast Furnace Auxiliaries Supervisor typically include a bachelor’s degree in Metallurgical Engineering or a related field, as well as several years of experience in blast furnace operations, auxiliaries systems, and Six Sigma methodologies.

What are the career prospects for a Blast Furnace Auxiliaries Supervisor?

The career prospects for a Blast Furnace Auxiliaries Supervisor are generally good, with opportunities for advancement to management positions within the iron and steel industry. With experience and additional education, Blast Furnace Auxiliaries Supervisors may also qualify for roles in other industries, such as manufacturing, engineering, and consulting.

What are the challenges faced by Blast Furnace Auxiliaries Supervisors?

The challenges faced by Blast Furnace Auxiliaries Supervisors can include managing a large team of employees, ensuring the smooth operation of complex blast furnace auxiliaries systems, meeting production targets, and implementing new technologies and processes.

What are the key skills required for a Blast Furnace Auxiliaries Supervisor?

The key skills required for a Blast Furnace Auxiliaries Supervisor include leadership, communication, problem-solving, decision-making, and analytical skills. Additionally, Blast Furnace Auxiliaries Supervisors should have a strong understanding of blast furnace operations, auxiliaries systems, and Six Sigma methodologies.

What is the work environment like for a Blast Furnace Auxiliaries Supervisor?

The work environment for a Blast Furnace Auxiliaries Supervisor is typically industrial, with exposure to noise, heat, and dust. Blast Furnace Auxiliaries Supervisors may also work long hours, including weekends and holidays.

What is the salary range for a Blast Furnace Auxiliaries Supervisor?

The salary range for a Blast Furnace Auxiliaries Supervisor can vary depending on factors such as experience, education, and location. According to Salary.com, the average salary for a Blast Furnace Auxiliaries Supervisor in the United States is $95,000 per year.

What are the benefits of working as a Blast Furnace Auxiliaries Supervisor?

The benefits of working as a Blast Furnace Auxiliaries Supervisor can include a competitive salary, comprehensive benefits package, and opportunities for advancement. Blast Furnace Auxiliaries Supervisors may also enjoy the satisfaction of working in a challenging and rewarding field.