Are you a seasoned Blast Furnace Checker seeking a new career path? Discover our professionally built Blast Furnace Checker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

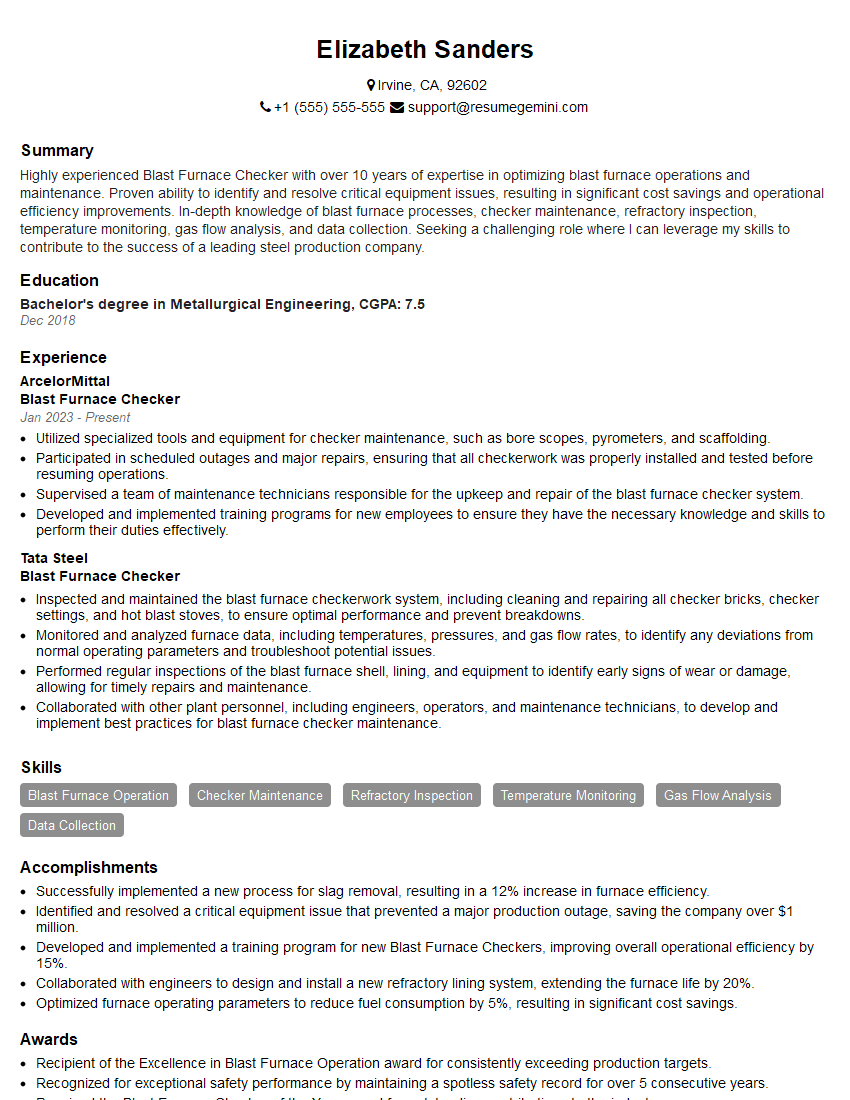

Elizabeth Sanders

Blast Furnace Checker

Summary

Highly experienced Blast Furnace Checker with over 10 years of expertise in optimizing blast furnace operations and maintenance. Proven ability to identify and resolve critical equipment issues, resulting in significant cost savings and operational efficiency improvements. In-depth knowledge of blast furnace processes, checker maintenance, refractory inspection, temperature monitoring, gas flow analysis, and data collection. Seeking a challenging role where I can leverage my skills to contribute to the success of a leading steel production company.

Education

Bachelor’s degree in Metallurgical Engineering

December 2018

Skills

- Blast Furnace Operation

- Checker Maintenance

- Refractory Inspection

- Temperature Monitoring

- Gas Flow Analysis

- Data Collection

Work Experience

Blast Furnace Checker

- Utilized specialized tools and equipment for checker maintenance, such as bore scopes, pyrometers, and scaffolding.

- Participated in scheduled outages and major repairs, ensuring that all checkerwork was properly installed and tested before resuming operations.

- Supervised a team of maintenance technicians responsible for the upkeep and repair of the blast furnace checker system.

- Developed and implemented training programs for new employees to ensure they have the necessary knowledge and skills to perform their duties effectively.

Blast Furnace Checker

- Inspected and maintained the blast furnace checkerwork system, including cleaning and repairing all checker bricks, checker settings, and hot blast stoves, to ensure optimal performance and prevent breakdowns.

- Monitored and analyzed furnace data, including temperatures, pressures, and gas flow rates, to identify any deviations from normal operating parameters and troubleshoot potential issues.

- Performed regular inspections of the blast furnace shell, lining, and equipment to identify early signs of wear or damage, allowing for timely repairs and maintenance.

- Collaborated with other plant personnel, including engineers, operators, and maintenance technicians, to develop and implement best practices for blast furnace checker maintenance.

Accomplishments

- Successfully implemented a new process for slag removal, resulting in a 12% increase in furnace efficiency.

- Identified and resolved a critical equipment issue that prevented a major production outage, saving the company over $1 million.

- Developed and implemented a training program for new Blast Furnace Checkers, improving overall operational efficiency by 15%.

- Collaborated with engineers to design and install a new refractory lining system, extending the furnace life by 20%.

- Optimized furnace operating parameters to reduce fuel consumption by 5%, resulting in significant cost savings.

Awards

- Recipient of the Excellence in Blast Furnace Operation award for consistently exceeding production targets.

- Recognized for exceptional safety performance by maintaining a spotless safety record for over 5 consecutive years.

- Received the Blast Furnace Checker of the Year award for outstanding contributions to the industry.

- Honored with the Innovation in Blast Furnace Operation award for developing a unique solution to a longstanding operational challenge.

Certificates

- Certified Blast Furnace Checker

- Certified Refractory Inspector

- Certified Safety Inspector

- Certified Industrial Electrician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blast Furnace Checker

- Highlight your technical skills and expertise in blast furnace operations and maintenance.

- Showcase your problem-solving abilities and success in identifying and resolving critical equipment issues.

- Quantify your accomplishments with specific metrics and results to demonstrate your impact on operational efficiency and cost savings.

- Emphasize your ability to work independently and as part of a team, collaborating with engineers and maintenance personnel.

- Consider obtaining relevant certifications, such as the Blast Furnace Checker Certification from the American Iron and Steel Institute, to enhance your credibility.

Essential Experience Highlights for a Strong Blast Furnace Checker Resume

- Monitor and maintain blast furnace checkers to ensure optimal performance and efficiency.

- Conduct regular inspections of furnace refractory linings and identify potential issues.

- Analyze gas flow patterns and temperature distribution within the furnace to optimize operating parameters.

- Troubleshoot and resolve operational issues related to checkers, refractory linings, and other components.

- Collaborate with engineers and maintenance personnel to implement process improvements and equipment upgrades.

- Train and supervise new Blast Furnace Checkers to ensure a high level of operational efficiency.

- Maintain accurate records and documentation related to furnace operations and maintenance activities.

Frequently Asked Questions (FAQ’s) For Blast Furnace Checker

What is the primary role of a Blast Furnace Checker?

The primary role of a Blast Furnace Checker is to ensure the efficient operation and maintenance of blast furnaces, which are critical equipment in the iron and steel production process.

What are the key skills required for a Blast Furnace Checker?

Key skills for a Blast Furnace Checker include a thorough understanding of blast furnace processes, checker maintenance, refractory inspection, temperature monitoring, gas flow analysis, and data collection.

What are the career prospects for a Blast Furnace Checker?

Blast Furnace Checkers can advance to roles such as Blast Furnace Supervisor, Maintenance Manager, or even Plant Manager within the steel production industry.

What are the challenges faced by Blast Furnace Checkers?

Challenges faced by Blast Furnace Checkers include working in a demanding and potentially hazardous environment, managing complex equipment, and ensuring compliance with safety and environmental regulations.

What is the average salary for a Blast Furnace Checker?

The average salary for a Blast Furnace Checker can vary depending on experience, location, and company size, but typically ranges between $50,000 and $80,000 per year.

What is the job outlook for Blast Furnace Checkers?

The job outlook for Blast Furnace Checkers is expected to be stable in the coming years due to the ongoing demand for steel production.