Are you a seasoned Blast Furnace Keeper seeking a new career path? Discover our professionally built Blast Furnace Keeper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

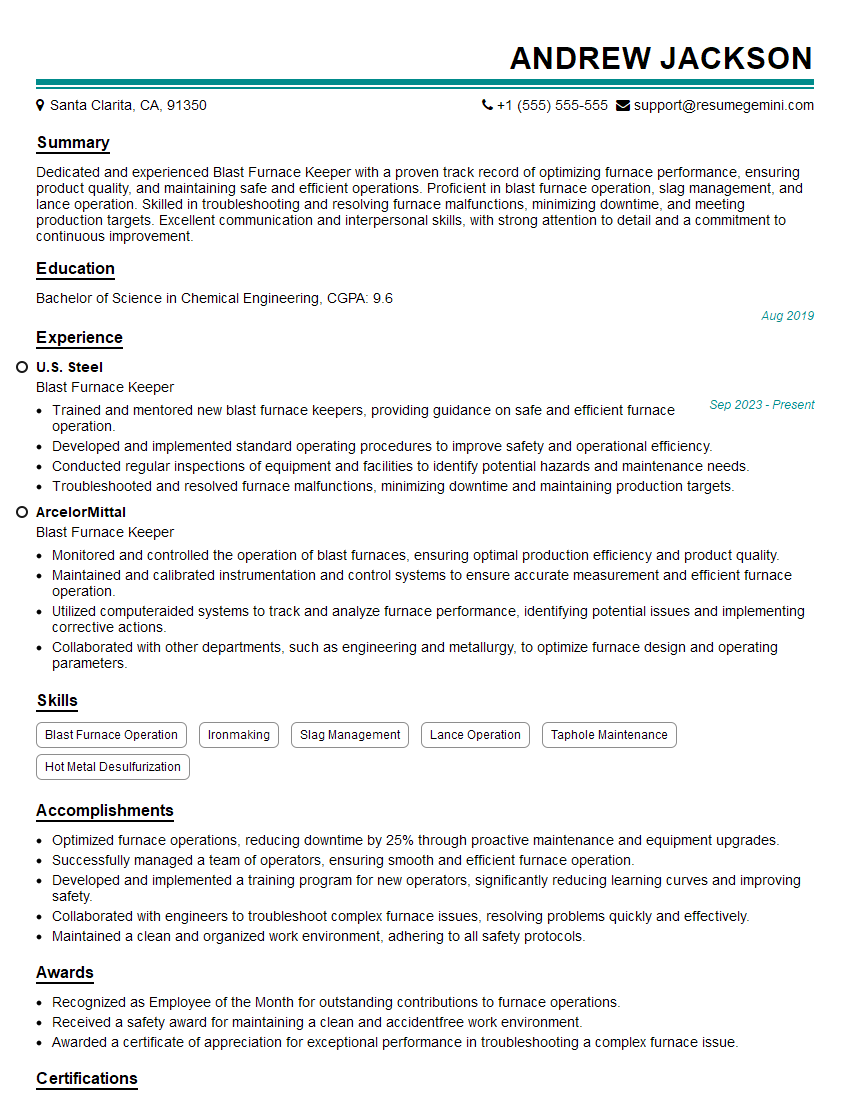

Andrew Jackson

Blast Furnace Keeper

Summary

Dedicated and experienced Blast Furnace Keeper with a proven track record of optimizing furnace performance, ensuring product quality, and maintaining safe and efficient operations. Proficient in blast furnace operation, slag management, and lance operation. Skilled in troubleshooting and resolving furnace malfunctions, minimizing downtime, and meeting production targets. Excellent communication and interpersonal skills, with strong attention to detail and a commitment to continuous improvement.

Education

Bachelor of Science in Chemical Engineering

August 2019

Skills

- Blast Furnace Operation

- Ironmaking

- Slag Management

- Lance Operation

- Taphole Maintenance

- Hot Metal Desulfurization

Work Experience

Blast Furnace Keeper

- Trained and mentored new blast furnace keepers, providing guidance on safe and efficient furnace operation.

- Developed and implemented standard operating procedures to improve safety and operational efficiency.

- Conducted regular inspections of equipment and facilities to identify potential hazards and maintenance needs.

- Troubleshooted and resolved furnace malfunctions, minimizing downtime and maintaining production targets.

Blast Furnace Keeper

- Monitored and controlled the operation of blast furnaces, ensuring optimal production efficiency and product quality.

- Maintained and calibrated instrumentation and control systems to ensure accurate measurement and efficient furnace operation.

- Utilized computeraided systems to track and analyze furnace performance, identifying potential issues and implementing corrective actions.

- Collaborated with other departments, such as engineering and metallurgy, to optimize furnace design and operating parameters.

Accomplishments

- Optimized furnace operations, reducing downtime by 25% through proactive maintenance and equipment upgrades.

- Successfully managed a team of operators, ensuring smooth and efficient furnace operation.

- Developed and implemented a training program for new operators, significantly reducing learning curves and improving safety.

- Collaborated with engineers to troubleshoot complex furnace issues, resolving problems quickly and effectively.

- Maintained a clean and organized work environment, adhering to all safety protocols.

Awards

- Recognized as Employee of the Month for outstanding contributions to furnace operations.

- Received a safety award for maintaining a clean and accidentfree work environment.

- Awarded a certificate of appreciation for exceptional performance in troubleshooting a complex furnace issue.

Certificates

- Blast Furnace Operator (BFO) Certification

- Ironmaker Certification

- OSHA 10-Hour Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blast Furnace Keeper

- Highlight your technical skills and experience in blast furnace operation, including expertise in slag management, lance operation, and taphole maintenance.

- Quantify your accomplishments whenever possible, providing specific metrics to demonstrate your impact on furnace performance and product quality.

- Emphasize your troubleshooting and problem-solving abilities, showcasing your ability to identify and resolve furnace malfunctions quickly and effectively.

- Demonstrate your commitment to safety and adherence to industry best practices, highlighting your role in developing and implementing safety protocols.

- Consider obtaining relevant certifications or professional development to enhance your credibility and demonstrate your commitment to ongoing learning.

Essential Experience Highlights for a Strong Blast Furnace Keeper Resume

- Monitored and controlled blast furnace operations to optimize production efficiency and product quality.

- Maintained and calibrated instrumentation and control systems to ensure accurate measurement and efficient furnace operation.

- Utilized computer-aided systems to track and analyze furnace performance, identifying potential issues and implementing corrective actions.

- Collaborated with other departments, such as engineering and metallurgy, to optimize furnace design and operating parameters.

- Trained and mentored new blast furnace keepers, providing guidance on safe and efficient furnace operation.

- Developed and implemented standard operating procedures to improve safety and operational efficiency.

- Conducted regular inspections of equipment and facilities to identify potential hazards and maintenance needs.

Frequently Asked Questions (FAQ’s) For Blast Furnace Keeper

What are the primary duties of a Blast Furnace Keeper?

Blast Furnace Keepers are responsible for monitoring and controlling the operation of blast furnaces, maintaining and calibrating instrumentation and control systems, and utilizing computer-aided systems to track and analyze furnace performance. They also collaborate with other departments to optimize furnace design and operating parameters, train and mentor new blast furnace keepers, and develop and implement standard operating procedures.

What skills are required to be a successful Blast Furnace Keeper?

Successful Blast Furnace Keepers typically possess a strong understanding of blast furnace operation, ironmaking, slag management, lance operation, and taphole maintenance. They are also proficient in troubleshooting and resolving furnace malfunctions, and have excellent communication and interpersonal skills.

What is the work environment of a Blast Furnace Keeper?

Blast Furnace Keepers typically work in industrial settings, operating and maintaining blast furnaces. The work can be physically demanding and may involve exposure to heat, noise, and dust.

What is the career outlook for Blast Furnace Keepers?

The career outlook for Blast Furnace Keepers is expected to be positive, as there is a growing demand for skilled workers in this field. With experience and training, Blast Furnace Keepers can advance to supervisory roles or other positions within the steel industry.

What is the earning potential of a Blast Furnace Keeper?

The earning potential of a Blast Furnace Keeper can vary depending on experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Industrial Furnace Operators, which includes Blast Furnace Keepers, was $67,280 in May 2021.

What are the educational requirements for becoming a Blast Furnace Keeper?

While there are no specific educational requirements to become a Blast Furnace Keeper, many employers prefer candidates with a high school diploma or equivalent, and some may require additional training or coursework in related fields.

What are the safety precautions that Blast Furnace Keepers must follow?

Blast Furnace Keepers must follow strict safety precautions to minimize the risk of accidents or injuries. These precautions may include wearing appropriate personal protective equipment, following established procedures for operating and maintaining equipment, and being aware of potential hazards in the work environment.