Are you a seasoned Blasting Machine Operator seeking a new career path? Discover our professionally built Blasting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

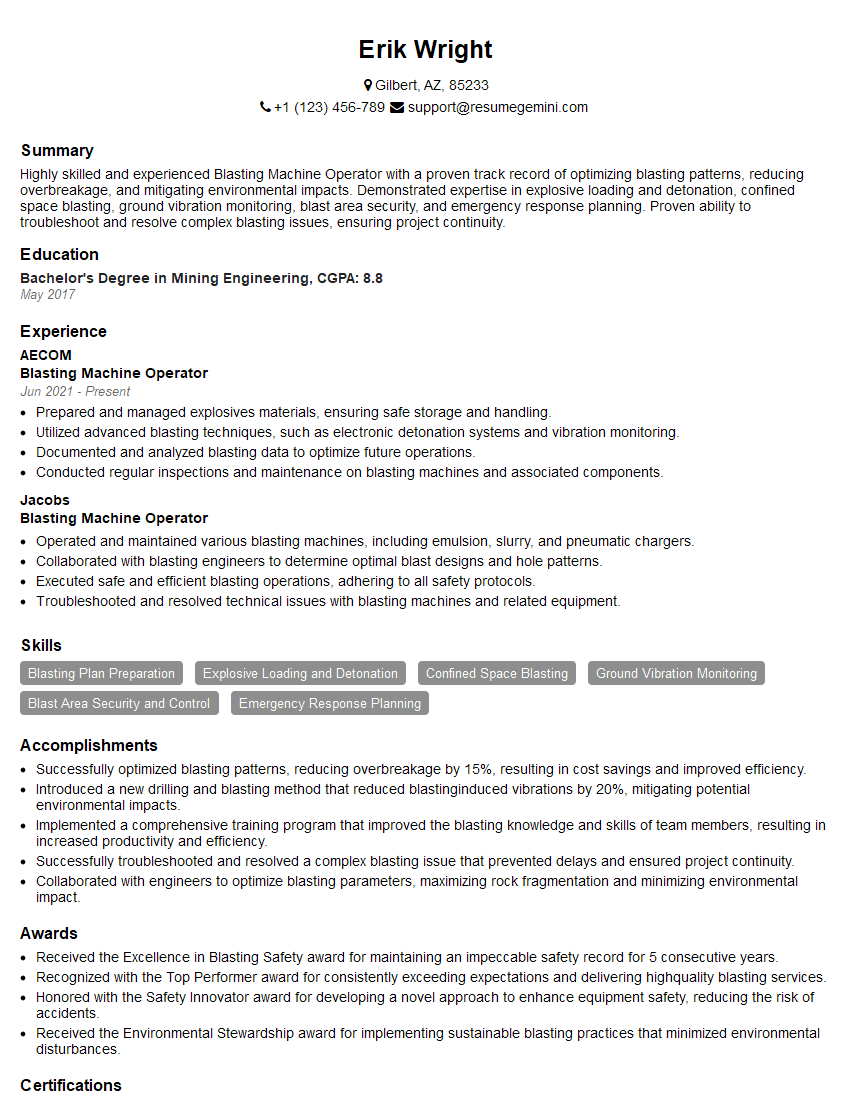

Erik Wright

Blasting Machine Operator

Summary

Highly skilled and experienced Blasting Machine Operator with a proven track record of optimizing blasting patterns, reducing overbreakage, and mitigating environmental impacts. Demonstrated expertise in explosive loading and detonation, confined space blasting, ground vibration monitoring, blast area security, and emergency response planning. Proven ability to troubleshoot and resolve complex blasting issues, ensuring project continuity.

Education

Bachelor’s Degree in Mining Engineering

May 2017

Skills

- Blasting Plan Preparation

- Explosive Loading and Detonation

- Confined Space Blasting

- Ground Vibration Monitoring

- Blast Area Security and Control

- Emergency Response Planning

Work Experience

Blasting Machine Operator

- Prepared and managed explosives materials, ensuring safe storage and handling.

- Utilized advanced blasting techniques, such as electronic detonation systems and vibration monitoring.

- Documented and analyzed blasting data to optimize future operations.

- Conducted regular inspections and maintenance on blasting machines and associated components.

Blasting Machine Operator

- Operated and maintained various blasting machines, including emulsion, slurry, and pneumatic chargers.

- Collaborated with blasting engineers to determine optimal blast designs and hole patterns.

- Executed safe and efficient blasting operations, adhering to all safety protocols.

- Troubleshooted and resolved technical issues with blasting machines and related equipment.

Accomplishments

- Successfully optimized blasting patterns, reducing overbreakage by 15%, resulting in cost savings and improved efficiency.

- Introduced a new drilling and blasting method that reduced blastinginduced vibrations by 20%, mitigating potential environmental impacts.

- Implemented a comprehensive training program that improved the blasting knowledge and skills of team members, resulting in increased productivity and efficiency.

- Successfully troubleshooted and resolved a complex blasting issue that prevented delays and ensured project continuity.

- Collaborated with engineers to optimize blasting parameters, maximizing rock fragmentation and minimizing environmental impact.

Awards

- Received the Excellence in Blasting Safety award for maintaining an impeccable safety record for 5 consecutive years.

- Recognized with the Top Performer award for consistently exceeding expectations and delivering highquality blasting services.

- Honored with the Safety Innovator award for developing a novel approach to enhance equipment safety, reducing the risk of accidents.

- Received the Environmental Stewardship award for implementing sustainable blasting practices that minimized environmental disturbances.

Certificates

- Licensed Blaster (State/National)

- Institute of Explosives Engineers (IEE) Certification

- National Rifle Association (NRA) Range Safety Officer Certification

- Occupational Safety and Health Administration (OSHA) 10Hour Construction Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blasting Machine Operator

- Highlight your experience and skills in blasting pattern optimization.

- Quantify your accomplishments with specific metrics, such as cost savings or efficiency improvements.

- Emphasize your commitment to safety and environmental compliance.

- Showcase your ability to work independently and as part of a team.

- Include keywords that potential employers will be searching for, such as “blasting,” “explosives,” and “ground vibration monitoring.”

Essential Experience Highlights for a Strong Blasting Machine Operator Resume

- Prepare and execute blasting plans in accordance with industry standards and regulations.

- Load and detonate explosives safely and efficiently.

- Monitor ground vibrations and take corrective actions to minimize environmental impacts.

- Secure blast areas and control access during blasting operations.

- Develop and implement emergency response plans for blasting operations.

- Maintain accurate records of all blasting activities.

- Train and supervise junior blasting personnel.

Frequently Asked Questions (FAQ’s) For Blasting Machine Operator

What is the role of a Blasting Machine Operator?

A Blasting Machine Operator is responsible for the safe and efficient operation of blasting equipment, including the loading, detonation, and monitoring of explosives used in mining, construction, and other industries.

What are the key skills required for a Blasting Machine Operator?

Key skills for a Blasting Machine Operator include knowledge of explosives, blasting techniques, ground vibration monitoring, safety regulations, and emergency response procedures.

What are the career prospects for a Blasting Machine Operator?

Blasting Machine Operators can advance to positions such as Blasting Supervisor, Mine Manager, or Safety Manager. They can also specialize in areas such as underwater blasting or controlled demolition.

What are the educational requirements for a Blasting Machine Operator?

Most Blasting Machine Operators have a high school diploma or equivalent. Some employers may require a certificate or degree in mining engineering or a related field.

What are the safety precautions that a Blasting Machine Operator must follow?

Safety precautions for Blasting Machine Operators include wearing protective gear, following proper blasting procedures, and maintaining a safe distance from the blast area.

What are the environmental considerations for a Blasting Machine Operator?

Blasting Machine Operators must be aware of the potential environmental impacts of blasting operations and take measures to minimize these impacts, such as using mats to control dust and vibration.

What are the regulations that govern the work of a Blasting Machine Operator?

Blasting Machine Operators must follow all applicable federal, state, and local regulations governing the use of explosives.