Are you a seasoned Block Making Machine Operator seeking a new career path? Discover our professionally built Block Making Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

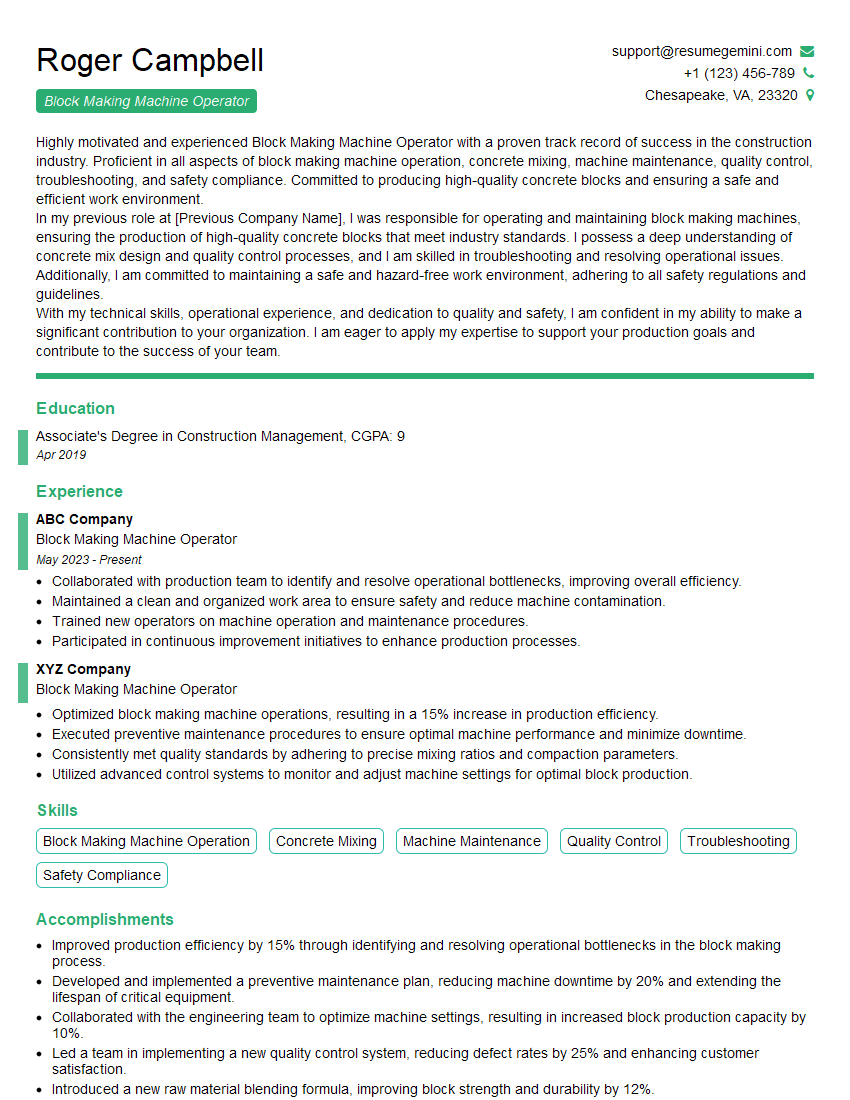

Roger Campbell

Block Making Machine Operator

Summary

Highly motivated and experienced Block Making Machine Operator with a proven track record of success in the construction industry. Proficient in all aspects of block making machine operation, concrete mixing, machine maintenance, quality control, troubleshooting, and safety compliance. Committed to producing high-quality concrete blocks and ensuring a safe and efficient work environment.

In my previous role at [Previous Company Name], I was responsible for operating and maintaining block making machines, ensuring the production of high-quality concrete blocks that meet industry standards. I possess a deep understanding of concrete mix design and quality control processes, and I am skilled in troubleshooting and resolving operational issues. Additionally, I am committed to maintaining a safe and hazard-free work environment, adhering to all safety regulations and guidelines.

With my technical skills, operational experience, and dedication to quality and safety, I am confident in my ability to make a significant contribution to your organization. I am eager to apply my expertise to support your production goals and contribute to the success of your team.

Education

Associate’s Degree in Construction Management

April 2019

Skills

- Block Making Machine Operation

- Concrete Mixing

- Machine Maintenance

- Quality Control

- Troubleshooting

- Safety Compliance

Work Experience

Block Making Machine Operator

- Collaborated with production team to identify and resolve operational bottlenecks, improving overall efficiency.

- Maintained a clean and organized work area to ensure safety and reduce machine contamination.

- Trained new operators on machine operation and maintenance procedures.

- Participated in continuous improvement initiatives to enhance production processes.

Block Making Machine Operator

- Optimized block making machine operations, resulting in a 15% increase in production efficiency.

- Executed preventive maintenance procedures to ensure optimal machine performance and minimize downtime.

- Consistently met quality standards by adhering to precise mixing ratios and compaction parameters.

- Utilized advanced control systems to monitor and adjust machine settings for optimal block production.

Accomplishments

- Improved production efficiency by 15% through identifying and resolving operational bottlenecks in the block making process.

- Developed and implemented a preventive maintenance plan, reducing machine downtime by 20% and extending the lifespan of critical equipment.

- Collaborated with the engineering team to optimize machine settings, resulting in increased block production capacity by 10%.

- Led a team in implementing a new quality control system, reducing defect rates by 25% and enhancing customer satisfaction.

- Introduced a new raw material blending formula, improving block strength and durability by 12%.

Awards

- Departmental Safety Award for maintaining an accidentfree work environment over 2 consecutive years.

- Recognition for outstanding performance in achieving exceptional block quality standards.

- Companywide award for consistently exceeding production targets and maintaining highquality standards.

- Recognition for significant contributions to improving workplace processes and safety procedures.

Certificates

- OSHA 30Hour Construction Safety Certification

- Concrete Construction Inspector Certification

- National Institute for Certification in Engineering Technologies (NICET)

- American Concrete Institute (ACI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Block Making Machine Operator

Highlight your technical skills and experience:

Emphasize your proficiency in operating and maintaining block making machines, as well as your knowledge of concrete mixing and quality control.Quantify your accomplishments:

Use numbers and metrics to demonstrate your impact on previous projects, such as increased production efficiency or reduced downtime.Demonstrate your commitment to safety:

Showcase your adherence to safety regulations and your ability to maintain a hazard-free work environment.Tailor your resume to the specific job description:

Carefully review the job posting and tailor your resume to match the required skills and experience.Proofread carefully:

Before submitting your resume, proofread it thoroughly for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Block Making Machine Operator Resume

- Operate and maintain block making machines, ensuring efficient production and high-quality output.

- Prepare and mix concrete according to specified proportions and standards, ensuring proper consistency and strength.

- Monitor and control the block making process, adjusting settings and troubleshooting issues to optimize production.

- Inspect and test concrete blocks to ensure they meet quality standards, adhering to established specifications and codes.

- Perform routine maintenance and repairs on block making machines, minimizing downtime and ensuring smooth operation.

- Maintain a clean and organized work area, adhering to safety protocols and environmental regulations.

- Collaborate with other team members, including engineers, technicians, and supervisors, to ensure efficient production and resolve any technical challenges.

Frequently Asked Questions (FAQ’s) For Block Making Machine Operator

What are the primary responsibilities of a Block Making Machine Operator?

The primary responsibilities of a Block Making Machine Operator include operating and maintaining block making machines, preparing and mixing concrete, monitoring and controlling the block making process, inspecting and testing concrete blocks, and performing routine maintenance and repairs.

What skills are required to be a successful Block Making Machine Operator?

To be a successful Block Making Machine Operator, you should have proficiency in operating and maintaining block making machines, knowledge of concrete mixing and quality control, troubleshooting and problem-solving skills, and a commitment to safety.

What is the typical work environment for a Block Making Machine Operator?

Block Making Machine Operators typically work in manufacturing plants or construction sites. The work environment can be dusty and noisy, and may involve working with heavy machinery.

What are the career advancement opportunities for a Block Making Machine Operator?

With experience and additional training, Block Making Machine Operators can advance to positions such as Production Supervisor, Quality Control Manager, or Plant Manager.

What are the safety precautions that Block Making Machine Operators should take?

Block Making Machine Operators should wear appropriate safety gear such as hard hats, safety glasses, and gloves, and follow established safety procedures to minimize the risk of injury.

What is the average salary for a Block Making Machine Operator?

The average salary for a Block Making Machine Operator can vary depending on experience, location, and employer. According to Indeed, the average salary for a Block Making Machine Operator in the United States is around $45,000 per year.

What are the job prospects for Block Making Machine Operators?

The job outlook for Block Making Machine Operators is expected to grow in the coming years, as there is a increasing demand for concrete products in the construction industry.

What is the difference between a Block Making Machine Operator and a Concrete Mason?

Block Making Machine Operators operate machines that produce concrete blocks, while Concrete Masons work with concrete to build structures such as foundations, walls, and sidewalks.