Are you a seasoned Blow Torch Operator seeking a new career path? Discover our professionally built Blow Torch Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

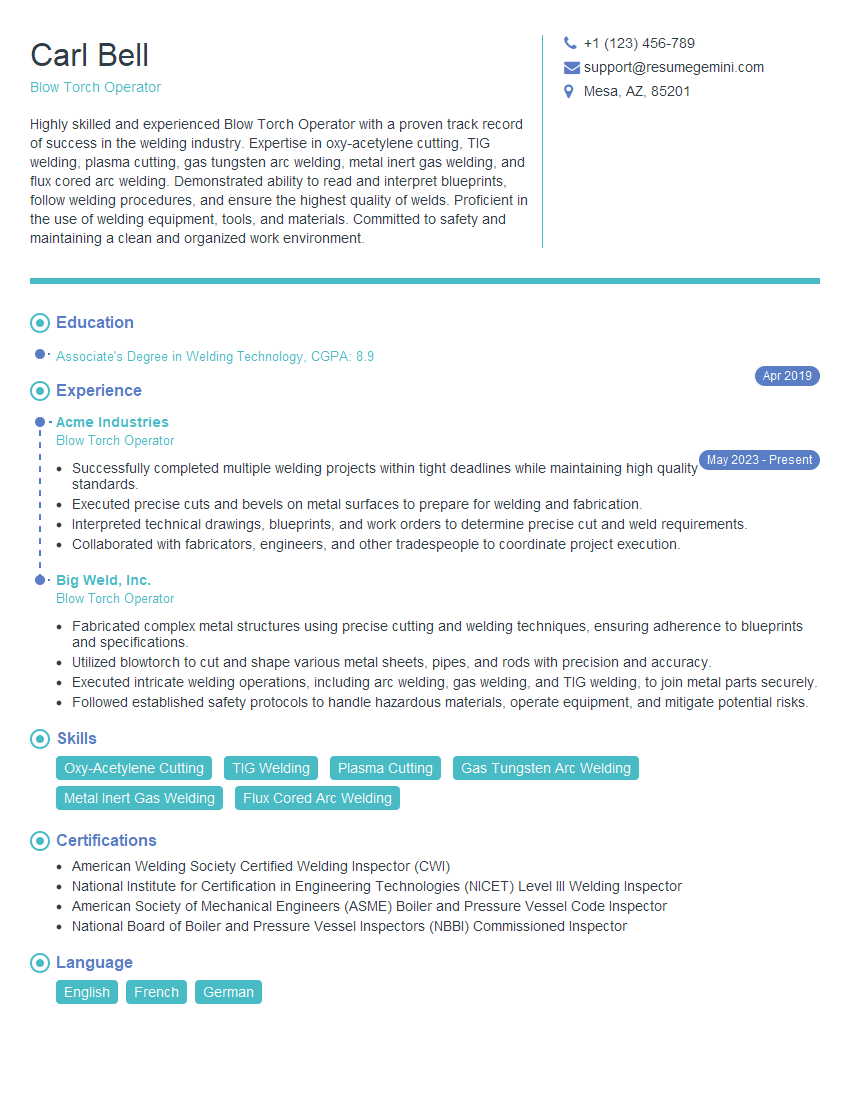

Carl Bell

Blow Torch Operator

Summary

Highly skilled and experienced Blow Torch Operator with a proven track record of success in the welding industry. Expertise in oxy-acetylene cutting, TIG welding, plasma cutting, gas tungsten arc welding, metal inert gas welding, and flux cored arc welding. Demonstrated ability to read and interpret blueprints, follow welding procedures, and ensure the highest quality of welds. Proficient in the use of welding equipment, tools, and materials. Committed to safety and maintaining a clean and organized work environment.

Education

Associate’s Degree in Welding Technology

April 2019

Skills

- Oxy-Acetylene Cutting

- TIG Welding

- Plasma Cutting

- Gas Tungsten Arc Welding

- Metal Inert Gas Welding

- Flux Cored Arc Welding

Work Experience

Blow Torch Operator

- Successfully completed multiple welding projects within tight deadlines while maintaining high quality standards.

- Executed precise cuts and bevels on metal surfaces to prepare for welding and fabrication.

- Interpreted technical drawings, blueprints, and work orders to determine precise cut and weld requirements.

- Collaborated with fabricators, engineers, and other tradespeople to coordinate project execution.

Blow Torch Operator

- Fabricated complex metal structures using precise cutting and welding techniques, ensuring adherence to blueprints and specifications.

- Utilized blowtorch to cut and shape various metal sheets, pipes, and rods with precision and accuracy.

- Executed intricate welding operations, including arc welding, gas welding, and TIG welding, to join metal parts securely.

- Followed established safety protocols to handle hazardous materials, operate equipment, and mitigate potential risks.

Certificates

- American Welding Society Certified Welding Inspector (CWI)

- National Institute for Certification in Engineering Technologies (NICET) Level III Welding Inspector

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Inspector

- National Board of Boiler and Pressure Vessel Inspectors (NBBI) Commissioned Inspector

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blow Torch Operator

- Highlight your experience with different welding techniques, such as oxy-acetylene cutting, TIG welding, plasma cutting, gas tungsten arc welding, metal inert gas welding, and flux cored arc welding.

- Showcase your ability to read and interpret blueprints, and follow welding procedures.

- Emphasize your commitment to safety and maintaining a clean and organized work environment.

- Quantify your accomplishments by providing specific examples of projects you have worked on and the results you achieved.

Essential Experience Highlights for a Strong Blow Torch Operator Resume

- Operate blow torch to cut, shape, and weld metal components

- Interpret blueprints and welding procedures to determine the appropriate welding techniques and equipment

- Set up and calibrate welding equipment, including blow torch, welding rods, and gas cylinders

- Inspect welds for defects and ensure they meet quality standards

- Maintain a clean and organized work area, and follow safety protocols

- Troubleshoot and resolve welding issues, and recommend solutions to improve welding processes

- Contribute to the development and implementation of new welding techniques and technologies

Frequently Asked Questions (FAQ’s) For Blow Torch Operator

What is the role of a Blow Torch Operator?

A Blow Torch Operator is responsible for cutting, shaping, and welding metal components using a blow torch. They interpret blueprints and welding procedures to determine the appropriate welding techniques and equipment, and set up and calibrate welding equipment. Blow Torch Operators inspect welds for defects and ensure they meet quality standards, and maintain a clean and organized work area.

What skills are required to be a Blow Torch Operator?

Blow Torch Operators typically need a high school diploma or equivalent, and some may have an associate’s degree in welding technology. They should have experience with different welding techniques, such as oxy-acetylene cutting, TIG welding, plasma cutting, gas tungsten arc welding, metal inert gas welding, and flux cored arc welding. Blow Torch Operators should also be able to read and interpret blueprints and welding procedures.

What is the work environment of a Blow Torch Operator?

Blow Torch Operators typically work in a manufacturing or fabrication environment. They may work indoors or outdoors, and may be exposed to fumes, noise, and heat. Blow Torch Operators must wear protective clothing and equipment, such as welding helmets, gloves, and respirators.

What are the career prospects for a Blow Torch Operator?

Blow Torch Operators can advance to positions such as welding supervisor or welding engineer. They may also start their own welding businesses. With experience and additional training, Blow Torch Operators can earn higher salaries and work on more complex projects.

What is the average salary for a Blow Torch Operator?

The average salary for a Blow Torch Operator is $40,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the benefits of being a Blow Torch Operator?

Blow Torch Operators can enjoy a number of benefits, including a steady income, the opportunity to learn a skilled trade, and the chance to work on a variety of projects.

What are the challenges of being a Blow Torch Operator?

Blow Torch Operators may face a number of challenges, including exposure to fumes, noise, and heat. They may also have to work in uncomfortable positions for extended periods of time.