Are you a seasoned Board Hammer Operator seeking a new career path? Discover our professionally built Board Hammer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

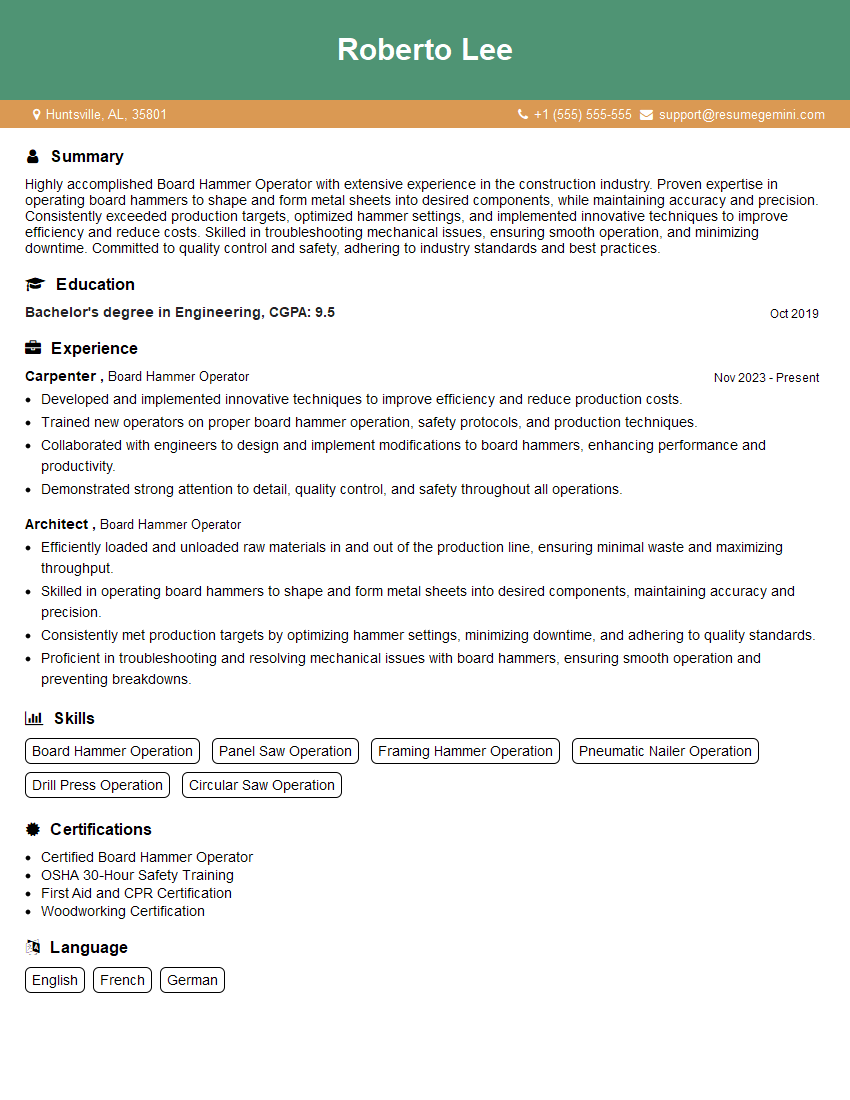

Roberto Lee

Board Hammer Operator

Summary

Highly accomplished Board Hammer Operator with extensive experience in the construction industry. Proven expertise in operating board hammers to shape and form metal sheets into desired components, while maintaining accuracy and precision. Consistently exceeded production targets, optimized hammer settings, and implemented innovative techniques to improve efficiency and reduce costs. Skilled in troubleshooting mechanical issues, ensuring smooth operation, and minimizing downtime. Committed to quality control and safety, adhering to industry standards and best practices.

Education

Bachelor’s degree in Engineering

October 2019

Skills

- Board Hammer Operation

- Panel Saw Operation

- Framing Hammer Operation

- Pneumatic Nailer Operation

- Drill Press Operation

- Circular Saw Operation

Work Experience

Board Hammer Operator

- Developed and implemented innovative techniques to improve efficiency and reduce production costs.

- Trained new operators on proper board hammer operation, safety protocols, and production techniques.

- Collaborated with engineers to design and implement modifications to board hammers, enhancing performance and productivity.

- Demonstrated strong attention to detail, quality control, and safety throughout all operations.

Board Hammer Operator

- Efficiently loaded and unloaded raw materials in and out of the production line, ensuring minimal waste and maximizing throughput.

- Skilled in operating board hammers to shape and form metal sheets into desired components, maintaining accuracy and precision.

- Consistently met production targets by optimizing hammer settings, minimizing downtime, and adhering to quality standards.

- Proficient in troubleshooting and resolving mechanical issues with board hammers, ensuring smooth operation and preventing breakdowns.

Certificates

- Certified Board Hammer Operator

- OSHA 30-Hour Safety Training

- First Aid and CPR Certification

- Woodworking Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Board Hammer Operator

- Highlight your skills and experience in operating board hammers, emphasizing your ability to achieve precision and accuracy.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of safety protocols and industry standards, demonstrating your commitment to a safe and compliant work environment.

- Include relevant certifications or training programs that you have completed.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Board Hammer Operator Resume

- Loaded and unloaded raw materials efficiently in and out of the production line.

- Skilled in operating board hammers to shape and form metal sheets into desired components.

- Consistently met production targets by optimizing hammer settings, minimizing downtime.

- Proficient in troubleshooting and resolving mechanical issues with board hammers.

- Developed and implemented innovative techniques to improve efficiency and reduce production costs.

- Trained new operators on proper board hammer operation, safety protocols, and production techniques.

- Collaborated with engineers to design and implement modifications to board hammers, enhancing performance and productivity.

- Demonstrated strong attention to detail, quality control, and safety throughout all operations.

Frequently Asked Questions (FAQ’s) For Board Hammer Operator

What is the primary role of a Board Hammer Operator?

The primary role of a Board Hammer Operator is to shape and form metal sheets into desired components using a board hammer, ensuring accuracy and precision while maintaining production targets and adhering to quality standards.

What skills are essential for a Board Hammer Operator?

Essential skills for a Board Hammer Operator include proficiency in operating board hammers, troubleshooting mechanical issues, optimizing hammer settings, implementing cost-saving techniques, and adhering to safety protocols.

What qualifications are typically required to become a Board Hammer Operator?

Typically, a high school diploma or equivalent is sufficient to qualify for a Board Hammer Operator position, although some employers may prefer candidates with a vocational or technical degree in a related field.

What are the career prospects for a Board Hammer Operator?

Board Hammer Operators with experience and a proven track record can advance to supervisory roles, such as Production Supervisor or Quality Control Inspector, or specialize in operating more complex machinery.

What is the average salary range for a Board Hammer Operator?

The average salary range for a Board Hammer Operator can vary depending on experience, location, and industry, but typically falls within the range of $20,000 to $40,000 annually.

What are the working conditions like for a Board Hammer Operator?

Board Hammer Operators typically work in manufacturing or construction environments, often standing for extended periods and operating machinery in potentially noisy and dusty conditions.

What safety precautions should a Board Hammer Operator take?

Board Hammer Operators should wear appropriate safety gear, follow established safety protocols, inspect equipment regularly, and receive proper training to minimize the risk of accidents and injuries.