Are you a seasoned Bondactor Machine Operator seeking a new career path? Discover our professionally built Bondactor Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

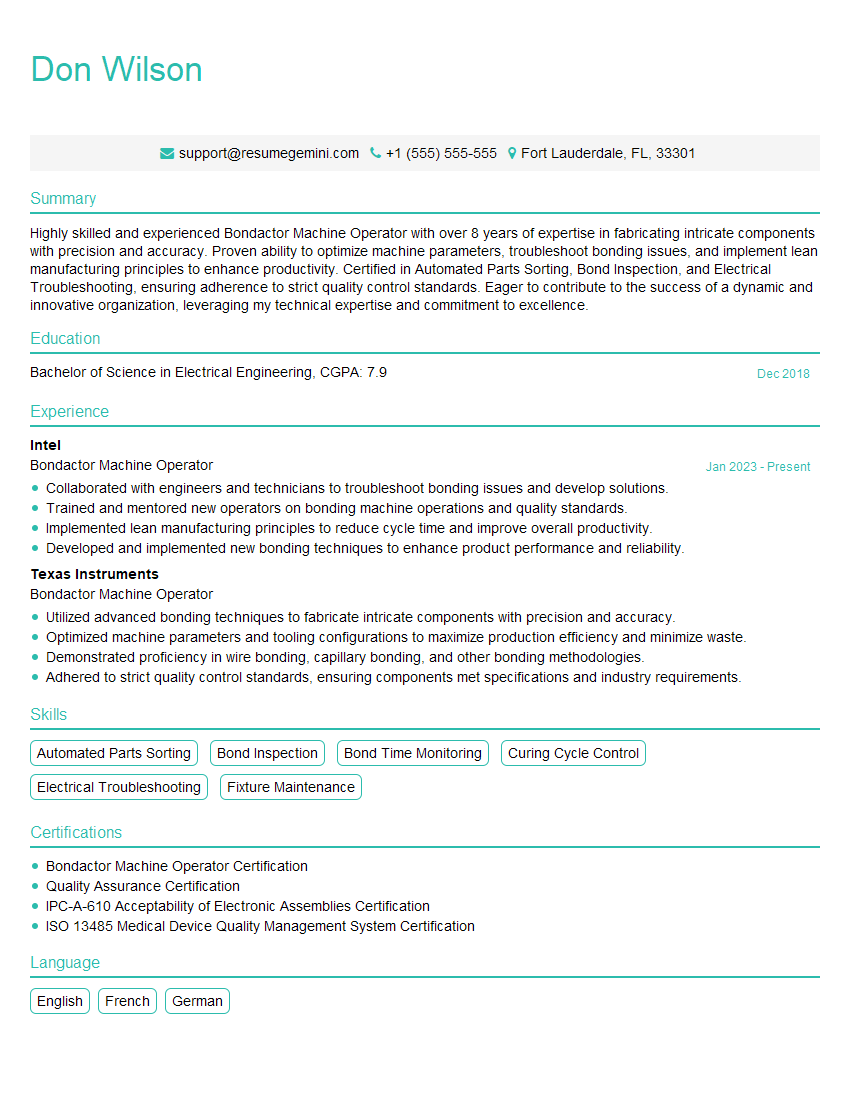

Don Wilson

Bondactor Machine Operator

Summary

Highly skilled and experienced Bondactor Machine Operator with over 8 years of expertise in fabricating intricate components with precision and accuracy. Proven ability to optimize machine parameters, troubleshoot bonding issues, and implement lean manufacturing principles to enhance productivity. Certified in Automated Parts Sorting, Bond Inspection, and Electrical Troubleshooting, ensuring adherence to strict quality control standards. Eager to contribute to the success of a dynamic and innovative organization, leveraging my technical expertise and commitment to excellence.

Education

Bachelor of Science in Electrical Engineering

December 2018

Skills

- Automated Parts Sorting

- Bond Inspection

- Bond Time Monitoring

- Curing Cycle Control

- Electrical Troubleshooting

- Fixture Maintenance

Work Experience

Bondactor Machine Operator

- Collaborated with engineers and technicians to troubleshoot bonding issues and develop solutions.

- Trained and mentored new operators on bonding machine operations and quality standards.

- Implemented lean manufacturing principles to reduce cycle time and improve overall productivity.

- Developed and implemented new bonding techniques to enhance product performance and reliability.

Bondactor Machine Operator

- Utilized advanced bonding techniques to fabricate intricate components with precision and accuracy.

- Optimized machine parameters and tooling configurations to maximize production efficiency and minimize waste.

- Demonstrated proficiency in wire bonding, capillary bonding, and other bonding methodologies.

- Adhered to strict quality control standards, ensuring components met specifications and industry requirements.

Certificates

- Bondactor Machine Operator Certification

- Quality Assurance Certification

- IPC-A-610 Acceptability of Electronic Assemblies Certification

- ISO 13485 Medical Device Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bondactor Machine Operator

- Highlight your expertise in advanced bonding techniques, such as wire bonding, capillary bonding, and thermal compression bonding.

- Quantify your accomplishments with specific metrics to demonstrate your impact on production efficiency, waste reduction, and quality improvement.

- Showcase your ability to troubleshoot and resolve complex bonding issues, providing examples of how you identified and implemented solutions.

- Emphasize your commitment to continuous improvement and your role in implementing lean manufacturing principles to optimize processes.

- Tailor your resume specifically to the job description, highlighting skills and experiences that align with the company’s requirements.

Essential Experience Highlights for a Strong Bondactor Machine Operator Resume

- Utilized advanced bonding techniques (e.g., wire bonding, capillary bonding) to fabricate complex components with high precision and accuracy.

- Optimized machine parameters and tooling configurations to maximize production efficiency, minimize waste, and enhance product quality.

- Adhered to stringent quality control standards and industry regulations to ensure components met specifications and exceeded customer expectations.

- Collaborated closely with engineers and technicians to diagnose and resolve bonding issues, develop innovative solutions, and improve processes.

- Trained and mentored junior operators on bonding machine operations, quality standards, and troubleshooting techniques.

- Incorporated lean manufacturing principles to streamline processes, reduce cycle time, and improve overall productivity.

- Developed and implemented new bonding techniques to enhance product performance, reliability, and cost-effectiveness.

Frequently Asked Questions (FAQ’s) For Bondactor Machine Operator

What are the key skills and qualifications required to become a successful Bondactor Machine Operator?

Essential skills for a Bondactor Machine Operator include proficiency in advanced bonding techniques, machine parameter optimization, quality control, troubleshooting, and lean manufacturing principles. Additionally, strong communication and teamwork abilities are crucial.

What industries utilize Bondactor Machine Operators?

Bondactor Machine Operators are employed in various industries, including electronics manufacturing, semiconductor fabrication, automotive, aerospace, and medical device manufacturing.

What are the career advancement opportunities for Bondactor Machine Operators?

With experience and additional training, Bondactor Machine Operators can advance to roles such as Bonding Technician, Bonding Engineer, or Production Supervisor. Some may also pursue management positions in manufacturing or quality control.

What is the job outlook for Bondactor Machine Operators?

The job outlook for Bondactor Machine Operators is expected to be positive in the coming years due to the increasing demand for electronic devices and components.

What are the typical working conditions for Bondactor Machine Operators?

Bondactor Machine Operators typically work in production environments, often in clean rooms or controlled environments. They may work shifts or overtime to meet production demands.

What are the safety considerations for Bondactor Machine Operators?

Bondactor Machine Operators must adhere to safety protocols, including proper handling of chemicals and equipment, wearing appropriate protective gear, and maintaining a clean and organized work area.

What certifications or training are beneficial for Bondactor Machine Operators?

Certifications in Automated Parts Sorting, Bond Inspection, and Electrical Troubleshooting are valuable for Bondactor Machine Operators. Additionally, training in lean manufacturing principles and quality control can enhance their skills and career prospects.

How can I prepare for a job interview as a Bondactor Machine Operator?

To prepare for a job interview as a Bondactor Machine Operator, research the company and the specific role. Practice answering common interview questions, such as those related to your experience, skills, and knowledge of bonding techniques. Be prepared to discuss your problem-solving abilities and commitment to quality.