Are you a seasoned Bone Char Kiln Operator seeking a new career path? Discover our professionally built Bone Char Kiln Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

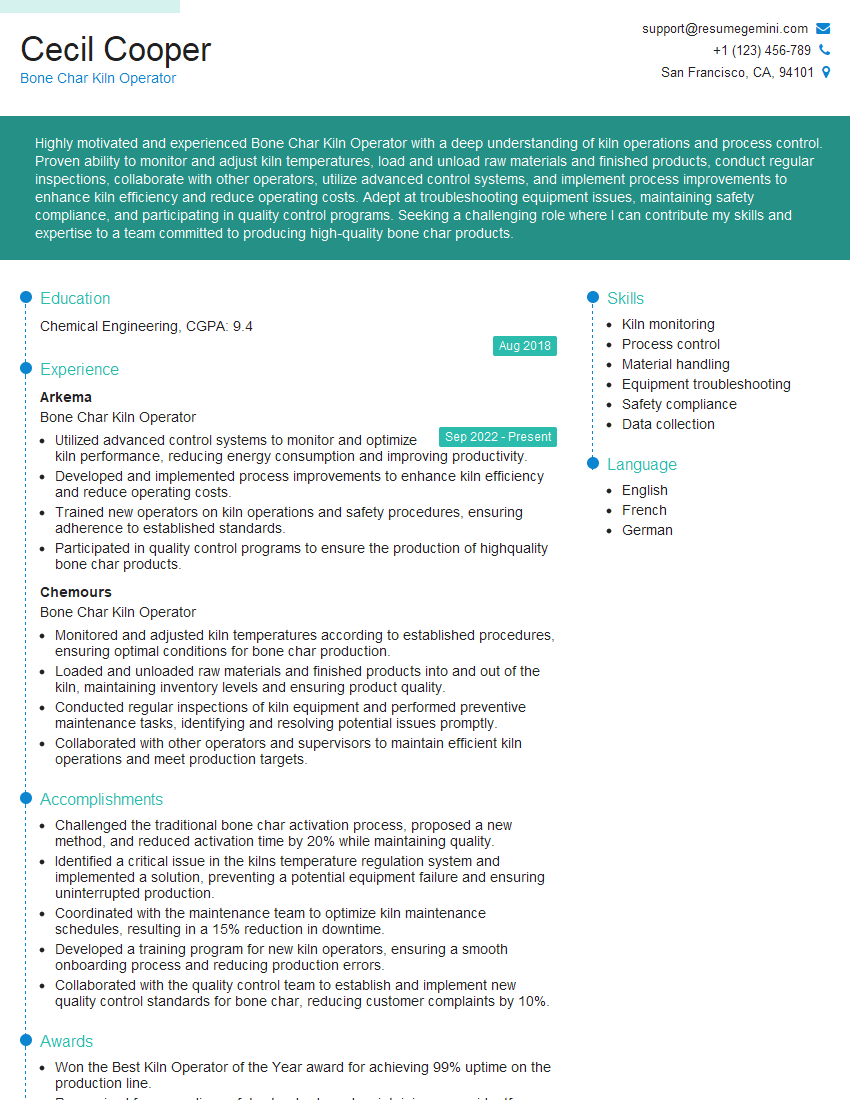

Cecil Cooper

Bone Char Kiln Operator

Summary

Highly motivated and experienced Bone Char Kiln Operator with a deep understanding of kiln operations and process control. Proven ability to monitor and adjust kiln temperatures, load and unload raw materials and finished products, conduct regular inspections, collaborate with other operators, utilize advanced control systems, and implement process improvements to enhance kiln efficiency and reduce operating costs. Adept at troubleshooting equipment issues, maintaining safety compliance, and participating in quality control programs. Seeking a challenging role where I can contribute my skills and expertise to a team committed to producing high-quality bone char products.

Education

Chemical Engineering

August 2018

Skills

- Kiln monitoring

- Process control

- Material handling

- Equipment troubleshooting

- Safety compliance

- Data collection

Work Experience

Bone Char Kiln Operator

- Utilized advanced control systems to monitor and optimize kiln performance, reducing energy consumption and improving productivity.

- Developed and implemented process improvements to enhance kiln efficiency and reduce operating costs.

- Trained new operators on kiln operations and safety procedures, ensuring adherence to established standards.

- Participated in quality control programs to ensure the production of highquality bone char products.

Bone Char Kiln Operator

- Monitored and adjusted kiln temperatures according to established procedures, ensuring optimal conditions for bone char production.

- Loaded and unloaded raw materials and finished products into and out of the kiln, maintaining inventory levels and ensuring product quality.

- Conducted regular inspections of kiln equipment and performed preventive maintenance tasks, identifying and resolving potential issues promptly.

- Collaborated with other operators and supervisors to maintain efficient kiln operations and meet production targets.

Accomplishments

- Challenged the traditional bone char activation process, proposed a new method, and reduced activation time by 20% while maintaining quality.

- Identified a critical issue in the kilns temperature regulation system and implemented a solution, preventing a potential equipment failure and ensuring uninterrupted production.

- Coordinated with the maintenance team to optimize kiln maintenance schedules, resulting in a 15% reduction in downtime.

- Developed a training program for new kiln operators, ensuring a smooth onboarding process and reducing production errors.

- Collaborated with the quality control team to establish and implement new quality control standards for bone char, reducing customer complaints by 10%.

Awards

- Won the Best Kiln Operator of the Year award for achieving 99% uptime on the production line.

- Recognized for exceeding safety standards and maintaining an accidentfree work environment for over five years.

- Received a Continuous Improvement Award for developing and implementing an automated monitoring system for the kiln, improving efficiency and product quality.

- Honored with the Outstanding Contribution Award for spearheading a project that improved the kilns energy efficiency by 12%.

Certificates

- Certified Bone Char Kiln Operator

- OSHA Hazmat Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bone Char Kiln Operator

- Quantify your accomplishments using specific metrics to demonstrate the impact of your work.

- Highlight your ability to work independently and as part of a team, showcasing your collaborative skills.

- Use keywords relevant to the job description to ensure your resume gets noticed by applicant tracking systems (ATS).

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

- Tailor your resume to each specific job you apply for, emphasizing the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Bone Char Kiln Operator Resume

- Monitored and adjusted kiln temperatures according to established procedures, ensuring optimal conditions for bone char production.

- Loaded and unloaded raw materials and finished products into and out of the kiln, maintaining inventory levels and ensuring product quality.

- Conducted regular inspections of kiln equipment and performed preventive maintenance tasks, identifying and resolving potential issues promptly.

- Collaborated with other operators and supervisors to maintain efficient kiln operations and meet production targets.

- Utilized advanced control systems to monitor and optimize kiln performance, reducing energy consumption and improving productivity.

- Developed and implemented process improvements to enhance kiln efficiency and reduce operating costs.

- Trained new operators on kiln operations and safety procedures, ensuring adherence to established standards.

- Participated in quality control programs to ensure the production of high-quality bone char products.

Frequently Asked Questions (FAQ’s) For Bone Char Kiln Operator

What is the primary responsibility of a Bone Char Kiln Operator?

The primary responsibility of a Bone Char Kiln Operator is to ensure the efficient operation and maintenance of bone char kilns, which are used to produce bone char, a carbon-rich material used in a variety of applications, including water filtration, sugar refining, and decolorizing agents.

What are the key skills required for a successful Bone Char Kiln Operator?

Key skills for a successful Bone Char Kiln Operator include knowledge of kiln operations, process control, material handling, equipment troubleshooting, safety compliance, and data collection. Additionally, a strong understanding of chemistry and physics is beneficial.

What is the career path for a Bone Char Kiln Operator?

With experience and additional training, Bone Char Kiln Operators can advance to supervisory roles, such as Kiln Supervisor or Production Manager. They may also move into roles in quality control, maintenance, or process engineering.

What is the average salary for a Bone Char Kiln Operator?

The average salary for a Bone Char Kiln Operator in the United States is approximately $50,000 per year. However, salaries can vary depending on experience, location, and the size of the company.

What is the job outlook for Bone Char Kiln Operators?

The job outlook for Bone Char Kiln Operators is expected to be stable in the coming years. The demand for bone char is expected to remain steady, as it is used in a variety of industries.

What are the working conditions for a Bone Char Kiln Operator?

Bone Char Kiln Operators typically work in industrial settings. They may be exposed to heat, noise, and dust. They must also be able to work independently and as part of a team.

What are the educational requirements for a Bone Char Kiln Operator?

While there are no specific educational requirements for a Bone Char Kiln Operator, many employers prefer candidates with a high school diploma or equivalent. Some employers may also require candidates to have experience in a related field, such as manufacturing or chemical processing.