Are you a seasoned Bottle House Quality Control Technician seeking a new career path? Discover our professionally built Bottle House Quality Control Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

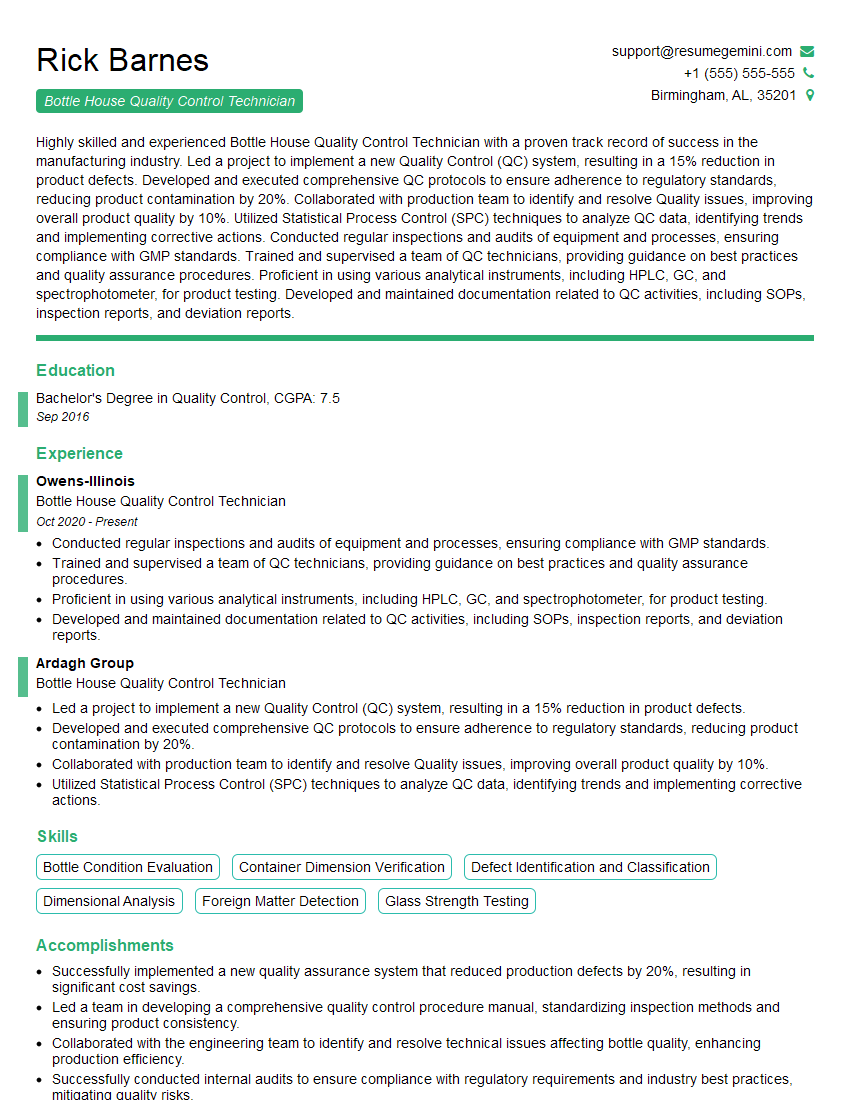

Rick Barnes

Bottle House Quality Control Technician

Summary

Highly skilled and experienced Bottle House Quality Control Technician with a proven track record of success in the manufacturing industry. Led a project to implement a new Quality Control (QC) system, resulting in a 15% reduction in product defects. Developed and executed comprehensive QC protocols to ensure adherence to regulatory standards, reducing product contamination by 20%. Collaborated with production team to identify and resolve Quality issues, improving overall product quality by 10%. Utilized Statistical Process Control (SPC) techniques to analyze QC data, identifying trends and implementing corrective actions. Conducted regular inspections and audits of equipment and processes, ensuring compliance with GMP standards. Trained and supervised a team of QC technicians, providing guidance on best practices and quality assurance procedures. Proficient in using various analytical instruments, including HPLC, GC, and spectrophotometer, for product testing. Developed and maintained documentation related to QC activities, including SOPs, inspection reports, and deviation reports.

Education

Bachelor’s Degree in Quality Control

September 2016

Skills

- Bottle Condition Evaluation

- Container Dimension Verification

- Defect Identification and Classification

- Dimensional Analysis

- Foreign Matter Detection

- Glass Strength Testing

Work Experience

Bottle House Quality Control Technician

- Conducted regular inspections and audits of equipment and processes, ensuring compliance with GMP standards.

- Trained and supervised a team of QC technicians, providing guidance on best practices and quality assurance procedures.

- Proficient in using various analytical instruments, including HPLC, GC, and spectrophotometer, for product testing.

- Developed and maintained documentation related to QC activities, including SOPs, inspection reports, and deviation reports.

Bottle House Quality Control Technician

- Led a project to implement a new Quality Control (QC) system, resulting in a 15% reduction in product defects.

- Developed and executed comprehensive QC protocols to ensure adherence to regulatory standards, reducing product contamination by 20%.

- Collaborated with production team to identify and resolve Quality issues, improving overall product quality by 10%.

- Utilized Statistical Process Control (SPC) techniques to analyze QC data, identifying trends and implementing corrective actions.

Accomplishments

- Successfully implemented a new quality assurance system that reduced production defects by 20%, resulting in significant cost savings.

- Led a team in developing a comprehensive quality control procedure manual, standardizing inspection methods and ensuring product consistency.

- Collaborated with the engineering team to identify and resolve technical issues affecting bottle quality, enhancing production efficiency.

- Successfully conducted internal audits to ensure compliance with regulatory requirements and industry best practices, mitigating quality risks.

- Implemented a root cause analysis methodology to identify and resolve quality issues, preventing recurring problems and improving overall product quality.

Awards

- Received the Outstanding Quality Performance Award for consistently meeting and exceeding quality standards in glass bottle production.

- Recognized for exceptional attention to detail and accuracy in bottle inspection processes, minimizing the release of noncompliant products.

- Awarded the Employee of the Month for contributions to optimizing production processes, improving efficiency and reducing waste.

- Recognized for maintaining a clean and organized work environment, contributing to the overall safety and quality of bottle production.

Certificates

- Certified Quality Control Inspector (CQCI)

- ISO 9001:2015 Certification

- Six Sigma Green Belt

- Lean Six Sigma Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bottle House Quality Control Technician

- Highlight your experience in the glass manufacturing industry, particularly in quality control of bottle production.

- Demonstrate your knowledge of quality control principles, standards, and regulations.

- Showcase your ability to use analytical instruments and statistical process control techniques.

- Emphasize your leadership and communication skills, as you will be responsible for training and supervising a team of QC technicians.

Essential Experience Highlights for a Strong Bottle House Quality Control Technician Resume

- Evaluated bottle condition to ensure adherence to quality standards.

- Verified container dimensions to meet specifications and prevent defects.

- Identified and classified defects to determine the cause and implement corrective actions.

- Conducted dimensional analysis to ensure bottles met the required size and shape.

- Detected foreign matter in bottles to prevent contamination.

- Tested glass strength to ensure bottles could withstand pressure and handling.

- Prepared and maintained quality control reports and documentation.

Frequently Asked Questions (FAQ’s) For Bottle House Quality Control Technician

What are the primary responsibilities of a Bottle House Quality Control Technician?

The primary responsibilities include evaluating bottle condition, verifying container dimensions, identifying and classifying defects, conducting dimensional analysis, detecting foreign matter, testing glass strength, and preparing quality control reports.

What qualifications are required to become a Bottle House Quality Control Technician?

Typically, a Bachelor’s Degree in Quality Control or a related field is required, along with experience in the glass manufacturing industry and knowledge of quality control principles and standards.

What are the career prospects for a Bottle House Quality Control Technician?

With experience and additional qualifications, you can advance to roles such as Quality Control Supervisor, Quality Manager, or Technical Manager within the glass manufacturing industry.

What are the challenges faced by a Bottle House Quality Control Technician?

Ensuring product quality while maintaining production efficiency, staying up-to-date with industry standards and regulations, and working in a fast-paced manufacturing environment are some of the common challenges.

What are the key skills required for a Bottle House Quality Control Technician?

Attention to detail, analytical thinking, problem-solving abilities, knowledge of quality control techniques, and proficiency in using analytical instruments are essential skills for this role.

What is the work environment of a Bottle House Quality Control Technician?

Typically, you will work in a manufacturing facility, following safety protocols and wearing appropriate personal protective equipment in a fast-paced environment.