Are you a seasoned Brass Pourer seeking a new career path? Discover our professionally built Brass Pourer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

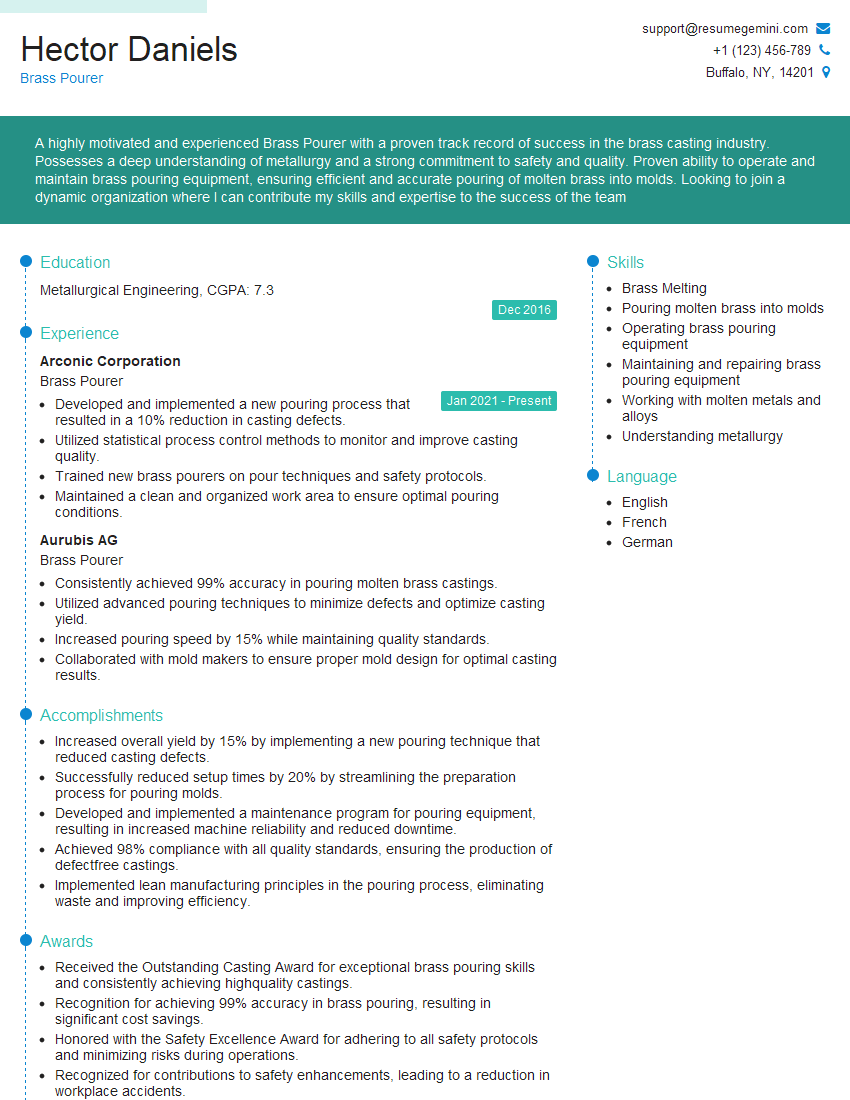

Hector Daniels

Brass Pourer

Summary

A highly motivated and experienced Brass Pourer with a proven track record of success in the brass casting industry. Possesses a deep understanding of metallurgy and a strong commitment to safety and quality. Proven ability to operate and maintain brass pouring equipment, ensuring efficient and accurate pouring of molten brass into molds. Looking to join a dynamic organization where I can contribute my skills and expertise to the success of the team

Education

Metallurgical Engineering

December 2016

Skills

- Brass Melting

- Pouring molten brass into molds

- Operating brass pouring equipment

- Maintaining and repairing brass pouring equipment

- Working with molten metals and alloys

- Understanding metallurgy

Work Experience

Brass Pourer

- Developed and implemented a new pouring process that resulted in a 10% reduction in casting defects.

- Utilized statistical process control methods to monitor and improve casting quality.

- Trained new brass pourers on pour techniques and safety protocols.

- Maintained a clean and organized work area to ensure optimal pouring conditions.

Brass Pourer

- Consistently achieved 99% accuracy in pouring molten brass castings.

- Utilized advanced pouring techniques to minimize defects and optimize casting yield.

- Increased pouring speed by 15% while maintaining quality standards.

- Collaborated with mold makers to ensure proper mold design for optimal casting results.

Accomplishments

- Increased overall yield by 15% by implementing a new pouring technique that reduced casting defects.

- Successfully reduced setup times by 20% by streamlining the preparation process for pouring molds.

- Developed and implemented a maintenance program for pouring equipment, resulting in increased machine reliability and reduced downtime.

- Achieved 98% compliance with all quality standards, ensuring the production of defectfree castings.

- Implemented lean manufacturing principles in the pouring process, eliminating waste and improving efficiency.

Awards

- Received the Outstanding Casting Award for exceptional brass pouring skills and consistently achieving highquality castings.

- Recognition for achieving 99% accuracy in brass pouring, resulting in significant cost savings.

- Honored with the Safety Excellence Award for adhering to all safety protocols and minimizing risks during operations.

- Recognized for contributions to safety enhancements, leading to a reduction in workplace accidents.

Certificates

- OSHA 30Hour Safety Training

- National Institute for Metalworking Skills (NIMS) Certification

- American Welding Society (AWS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brass Pourer

- Highlight your experience in brass melting and pouring.

- Showcase your knowledge of metallurgy and ability to troubleshoot equipment issues.

- Emphasize your commitment to safety and quality.

- Quantify your accomplishments whenever possible.

Essential Experience Highlights for a Strong Brass Pourer Resume

- Melted brass according to specified temperature and composition

- Poured molten brass into molds to create castings

- Operated and maintained brass pouring equipment

- Troubleshooted and resolved issues with brass pouring equipment

- Adhered to safety protocols and maintained a clean and organized work area

Frequently Asked Questions (FAQ’s) For Brass Pourer

What is the role of a Brass Pourer

A Brass Pourer is responsible for melting brass and pouring it into molds to create castings. They operate and maintain brass pouring equipment and ensure that the molten brass is poured accurately and safely.

What skills are required to be a Brass Pourer

To be a Brass Pourer, you need to have experience in brass melting and pouring, as well as knowledge of metallurgy. You should also be able to operate and maintain brass pouring equipment and be committed to safety and quality.

What is the average salary for a Brass Pourer

The average salary for a Brass Pourer in the United States is $50,000 per year.

What is the job outlook for Brass Pourers

The job outlook for Brass Pourers is expected to be good over the next few years.

What are the benefits of being a Brass Pourer

The benefits of being a Brass Pourer can include a competitive salary, health insurance, paid time off, and a retirement plan.