Are you a seasoned Breakdown Worker seeking a new career path? Discover our professionally built Breakdown Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

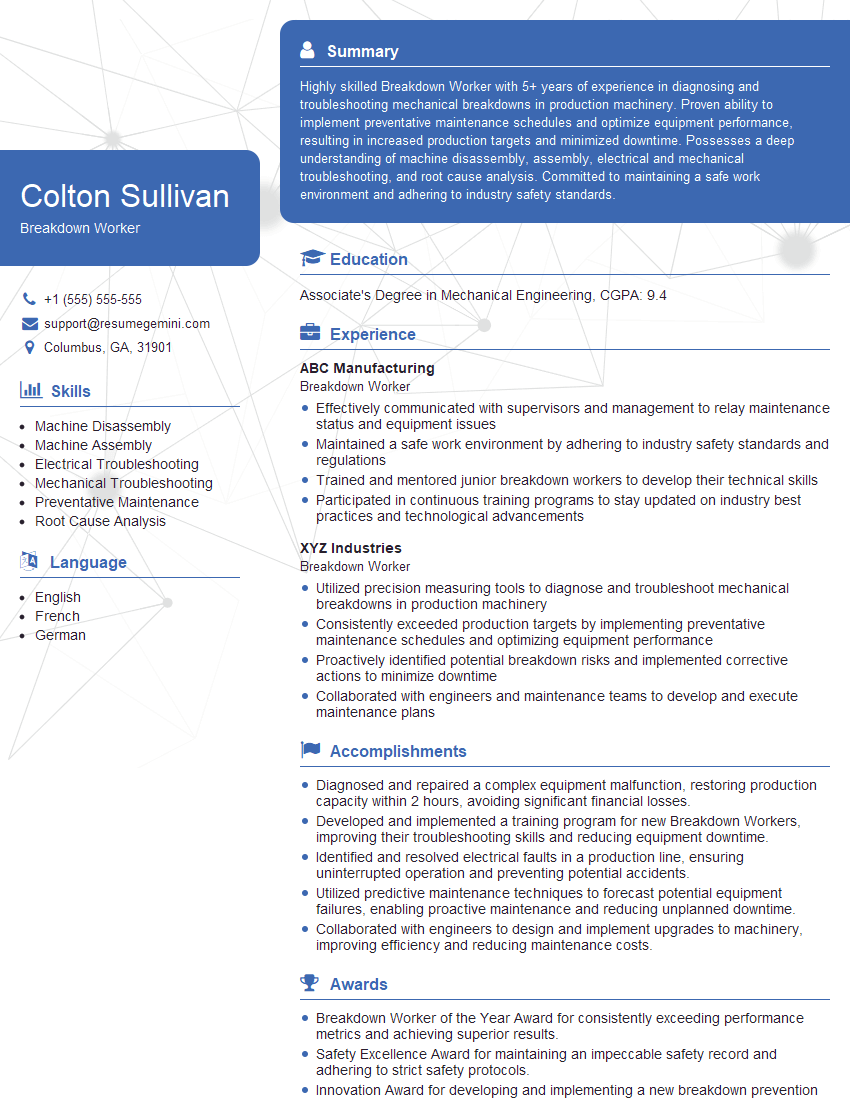

Colton Sullivan

Breakdown Worker

Summary

Highly skilled Breakdown Worker with 5+ years of experience in diagnosing and troubleshooting mechanical breakdowns in production machinery. Proven ability to implement preventative maintenance schedules and optimize equipment performance, resulting in increased production targets and minimized downtime. Possesses a deep understanding of machine disassembly, assembly, electrical and mechanical troubleshooting, and root cause analysis. Committed to maintaining a safe work environment and adhering to industry safety standards.

Education

Associate’s Degree in Mechanical Engineering

August 2015

Skills

- Machine Disassembly

- Machine Assembly

- Electrical Troubleshooting

- Mechanical Troubleshooting

- Preventative Maintenance

- Root Cause Analysis

Work Experience

Breakdown Worker

- Effectively communicated with supervisors and management to relay maintenance status and equipment issues

- Maintained a safe work environment by adhering to industry safety standards and regulations

- Trained and mentored junior breakdown workers to develop their technical skills

- Participated in continuous training programs to stay updated on industry best practices and technological advancements

Breakdown Worker

- Utilized precision measuring tools to diagnose and troubleshoot mechanical breakdowns in production machinery

- Consistently exceeded production targets by implementing preventative maintenance schedules and optimizing equipment performance

- Proactively identified potential breakdown risks and implemented corrective actions to minimize downtime

- Collaborated with engineers and maintenance teams to develop and execute maintenance plans

Accomplishments

- Diagnosed and repaired a complex equipment malfunction, restoring production capacity within 2 hours, avoiding significant financial losses.

- Developed and implemented a training program for new Breakdown Workers, improving their troubleshooting skills and reducing equipment downtime.

- Identified and resolved electrical faults in a production line, ensuring uninterrupted operation and preventing potential accidents.

- Utilized predictive maintenance techniques to forecast potential equipment failures, enabling proactive maintenance and reducing unplanned downtime.

- Collaborated with engineers to design and implement upgrades to machinery, improving efficiency and reducing maintenance costs.

Awards

- Breakdown Worker of the Year Award for consistently exceeding performance metrics and achieving superior results.

- Safety Excellence Award for maintaining an impeccable safety record and adhering to strict safety protocols.

- Innovation Award for developing and implementing a new breakdown prevention method that significantly reduced downtime.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Maintenance Manager (CMM)

- Certified Predictive Maintenance Technician (CPMT)

- Certified Vibration Analyst (CAT III)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Breakdown Worker

- Highlight your hands-on experience in machinery repair and maintenance.

- Quantify your accomplishments with specific metrics, such as increased production or reduced downtime.

- Demonstrate your knowledge of preventative maintenance techniques and industry best practices.

- Showcase your communication and teamwork skills, as breakdowns often require collaboration.

- Obtain relevant certifications or attend training programs to enhance your credibility.

Essential Experience Highlights for a Strong Breakdown Worker Resume

- Diagnose and troubleshoot mechanical breakdowns in production machinery using precision measuring tools.

- Implement preventative maintenance schedules and optimize equipment performance to exceed production targets.

- Identify potential breakdown risks and implement corrective actions to minimize downtime.

- Collaborate with engineers and maintenance teams to develop and execute maintenance plans.

- Communicate effectively with supervisors and management to relay maintenance status and equipment issues.

- Maintain a safe work environment by adhering to industry safety standards and regulations.

- Train and mentor junior breakdown workers to develop their technical skills.

Frequently Asked Questions (FAQ’s) For Breakdown Worker

What are the primary responsibilities of a Breakdown Worker?

Breakdown Workers diagnose and troubleshoot mechanical breakdowns in production machinery, implement preventative maintenance schedules, and collaborate with maintenance teams to ensure optimal equipment performance.

What skills are essential for a successful Breakdown Worker?

Essential skills include machine disassembly and assembly, electrical and mechanical troubleshooting, preventative maintenance, root cause analysis, and communication.

What industries typically employ Breakdown Workers?

Breakdown Workers are employed in various industries that rely on production machinery, such as manufacturing, automotive, and food processing.

What is the career progression path for a Breakdown Worker?

With experience, Breakdown Workers can advance to roles such as Maintenance Technician, Maintenance Supervisor, or Plant Engineer.

How can I become a Breakdown Worker?

To become a Breakdown Worker, you typically need an Associate’s Degree in Mechanical Engineering or a related field, along with hands-on experience in machinery repair and maintenance.