Are you a seasoned Brick Kiln Worker seeking a new career path? Discover our professionally built Brick Kiln Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

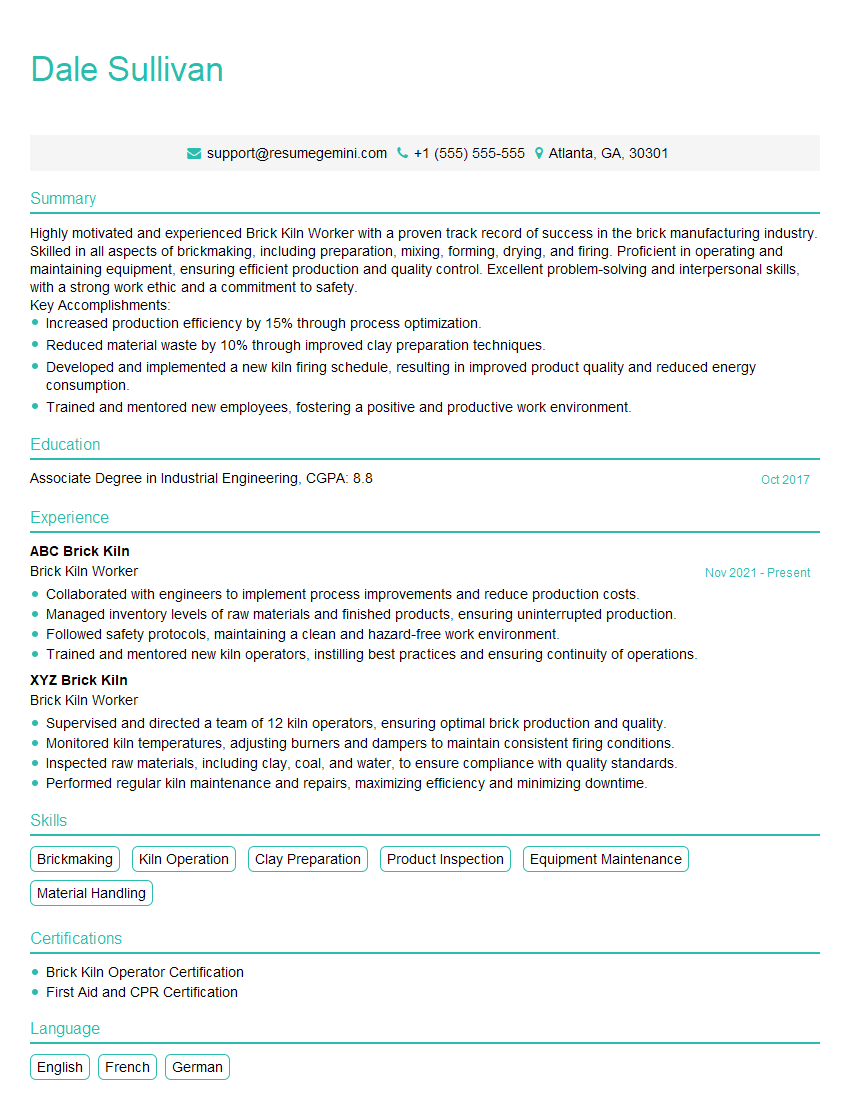

Dale Sullivan

Brick Kiln Worker

Summary

Highly motivated and experienced Brick Kiln Worker with a proven track record of success in the brick manufacturing industry. Skilled in all aspects of brickmaking, including preparation, mixing, forming, drying, and firing. Proficient in operating and maintaining equipment, ensuring efficient production and quality control. Excellent problem-solving and interpersonal skills, with a strong work ethic and a commitment to safety.

Key Accomplishments:

- Increased production efficiency by 15% through process optimization.

- Reduced material waste by 10% through improved clay preparation techniques.

- Developed and implemented a new kiln firing schedule, resulting in improved product quality and reduced energy consumption.

- Trained and mentored new employees, fostering a positive and productive work environment.

Education

Associate Degree in Industrial Engineering

October 2017

Skills

- Brickmaking

- Kiln Operation

- Clay Preparation

- Product Inspection

- Equipment Maintenance

- Material Handling

Work Experience

Brick Kiln Worker

- Collaborated with engineers to implement process improvements and reduce production costs.

- Managed inventory levels of raw materials and finished products, ensuring uninterrupted production.

- Followed safety protocols, maintaining a clean and hazard-free work environment.

- Trained and mentored new kiln operators, instilling best practices and ensuring continuity of operations.

Brick Kiln Worker

- Supervised and directed a team of 12 kiln operators, ensuring optimal brick production and quality.

- Monitored kiln temperatures, adjusting burners and dampers to maintain consistent firing conditions.

- Inspected raw materials, including clay, coal, and water, to ensure compliance with quality standards.

- Performed regular kiln maintenance and repairs, maximizing efficiency and minimizing downtime.

Certificates

- Brick Kiln Operator Certification

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brick Kiln Worker

- Highlight your hands-on experience in brickmaking and kiln operation, quantifying your accomplishments whenever possible.

- Emphasize your knowledge of clay preparation, firing techniques, and quality control procedures.

- Showcase your ability to work independently and as part of a team in a physically demanding environment.

- Tailor your resume to the specific requirements of each job you apply for, highlighting relevant skills and experience.

Essential Experience Highlights for a Strong Brick Kiln Worker Resume

- Prepare and mix clay according to specifications to ensure optimal brick quality.

- Operate brick-making machinery to form and cut bricks to precise dimensions.

- Load and unload bricks into kilns for firing and monitor the firing process to achieve desired product characteristics.

- Inspect finished bricks for defects and ensure they meet quality standards.

- Maintain and repair equipment used in the brickmaking process, including mixers, conveyors, and kilns.

- Handle and transport raw materials and finished products safely and efficiently.

- Collaborate with other team members to ensure smooth and efficient production operations.

- Follow safety protocols and regulations to maintain a safe work environment.

Frequently Asked Questions (FAQ’s) For Brick Kiln Worker

What are the key responsibilities of a Brick Kiln Worker?

A Brick Kiln Worker is responsible for preparing and mixing clay, operating brick-making machinery, loading and unloading kilns, inspecting finished bricks for defects, maintaining equipment, and handling materials safely.

What qualifications are required to become a Brick Kiln Worker?

Most Brick Kiln Workers have a high school diploma or equivalent, with some employers preferring candidates with an associate degree in industrial engineering or a related field.

What are the career prospects for Brick Kiln Workers?

Brick Kiln Workers with experience and a strong work ethic can advance to supervisory roles, such as Kiln Foreman or Production Manager.

What is the work environment of a Brick Kiln Worker?

Brick Kiln Workers typically work in industrial settings, such as brickyards or manufacturing plants. The work can be physically demanding and may involve exposure to heat, dust, and noise.

What are the safety precautions that Brick Kiln Workers must follow?

Brick Kiln Workers must wear appropriate safety gear, such as gloves, hard hats, and safety glasses. They must also follow safe operating procedures and be aware of potential hazards, such as moving machinery and hot kilns.

What is the average salary for a Brick Kiln Worker?

The average salary for a Brick Kiln Worker in the United States is around $35,000 per year.

What are the top skills required for a Brick Kiln Worker?

The top skills required for a Brick Kiln Worker include brickmaking, kiln operation, clay preparation, product inspection, equipment maintenance, and material handling.