Are you a seasoned Brick Maker seeking a new career path? Discover our professionally built Brick Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

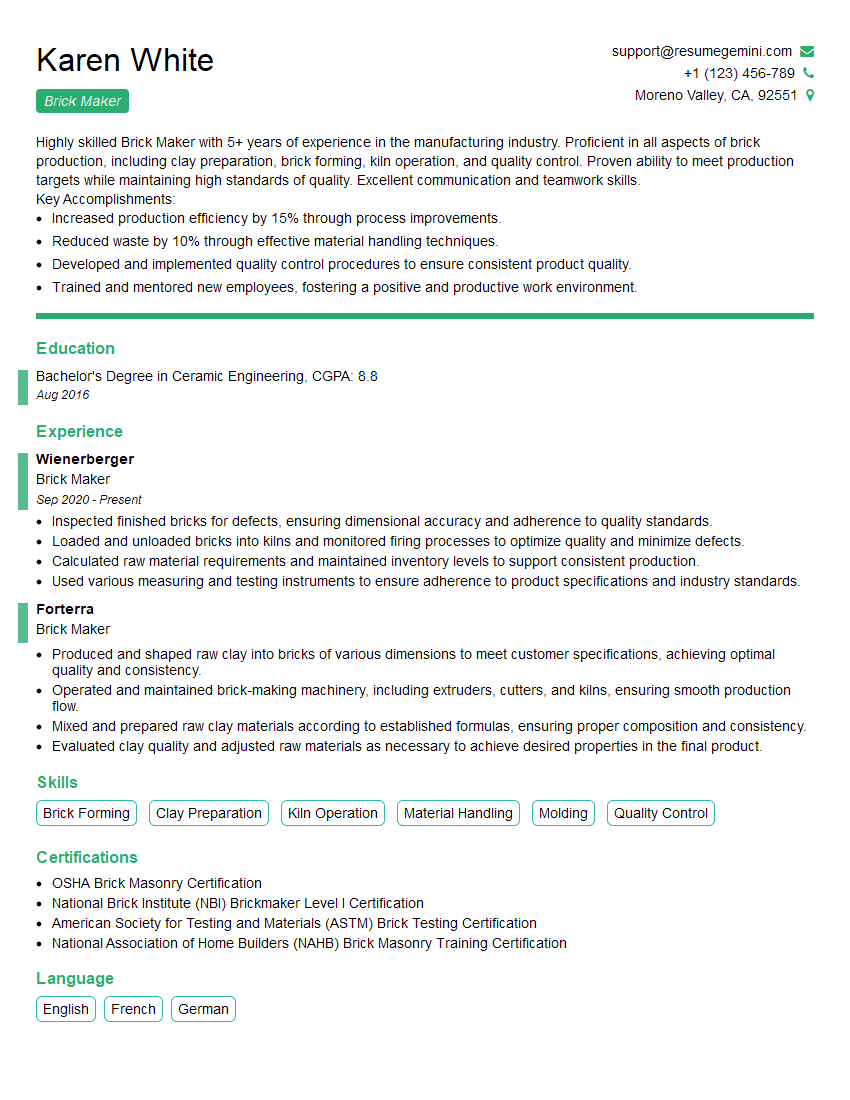

Karen White

Brick Maker

Summary

Highly skilled Brick Maker with 5+ years of experience in the manufacturing industry. Proficient in all aspects of brick production, including clay preparation, brick forming, kiln operation, and quality control. Proven ability to meet production targets while maintaining high standards of quality. Excellent communication and teamwork skills.

Key Accomplishments:

- Increased production efficiency by 15% through process improvements.

- Reduced waste by 10% through effective material handling techniques.

- Developed and implemented quality control procedures to ensure consistent product quality.

- Trained and mentored new employees, fostering a positive and productive work environment.

Education

Bachelor’s Degree in Ceramic Engineering

August 2016

Skills

- Brick Forming

- Clay Preparation

- Kiln Operation

- Material Handling

- Molding

- Quality Control

Work Experience

Brick Maker

- Inspected finished bricks for defects, ensuring dimensional accuracy and adherence to quality standards.

- Loaded and unloaded bricks into kilns and monitored firing processes to optimize quality and minimize defects.

- Calculated raw material requirements and maintained inventory levels to support consistent production.

- Used various measuring and testing instruments to ensure adherence to product specifications and industry standards.

Brick Maker

- Produced and shaped raw clay into bricks of various dimensions to meet customer specifications, achieving optimal quality and consistency.

- Operated and maintained brick-making machinery, including extruders, cutters, and kilns, ensuring smooth production flow.

- Mixed and prepared raw clay materials according to established formulas, ensuring proper composition and consistency.

- Evaluated clay quality and adjusted raw materials as necessary to achieve desired properties in the final product.

Certificates

- OSHA Brick Masonry Certification

- National Brick Institute (NBI) Brickmaker Level I Certification

- American Society for Testing and Materials (ASTM) Brick Testing Certification

- National Association of Home Builders (NAHB) Brick Masonry Training Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brick Maker

- Highlight your skills and experience in clay preparation, brick forming, kiln operation, and quality control.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Showcase your knowledge of brick manufacturing processes and industry best practices.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Brick Maker Resume

- Prepare clay by mixing, tempering, and molding it to the desired consistency.

- Operate kilns to fire bricks at high temperatures, ensuring proper firing and cooling.

- Monitor and control kiln temperature, atmosphere, and cooling rate to achieve desired brick properties.

- Inspect bricks for defects and ensure they meet quality standards.

- Maintain and repair equipment used in brick production, including mixers, extruders, and kilns.

- Load and unload bricks from kilns and transport them to storage or packaging areas.

- Adhere to safety regulations and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Brick Maker

What are the key skills required to be a successful Brick Maker?

The key skills required to be a successful Brick Maker include: clay preparation, brick forming, kiln operation, material handling, molding, and quality control.

What are the educational requirements to become a Brick Maker?

While there are no formal educational requirements to become a Brick Maker, many employers prefer candidates with a high school diploma or equivalent. Some Brick Makers may also have a degree in a related field, such as Ceramic Engineering.

What is the average salary for a Brick Maker?

The average salary for a Brick Maker in the United States is around $35,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the job prospects for Brick Makers?

The job prospects for Brick Makers are expected to be stable over the next few years. As the construction industry continues to grow, there will be a continued demand for skilled Brick Makers.

What are the working conditions for Brick Makers?

Brick Makers typically work in factories or plants. The work can be physically demanding, as it involves lifting and moving heavy materials. Brick Makers may also be exposed to dust, heat, and noise.

What are the career advancement opportunities for Brick Makers?

Brick Makers can advance their careers by becoming supervisors or managers. They may also specialize in a particular area of brickmaking, such as kiln operation or quality control.

What are the benefits of working as a Brick Maker?

The benefits of working as a Brick Maker include: job security, a steady income, and the oportunidad to work with your hands.

What are the challenges of working as a Brick Maker?

The challenges of working as a Brick Maker include: the physically demanding work, the exposure to dust and heat, and the potential for injuries.