Are you a seasoned Bridge Saw Operator seeking a new career path? Discover our professionally built Bridge Saw Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

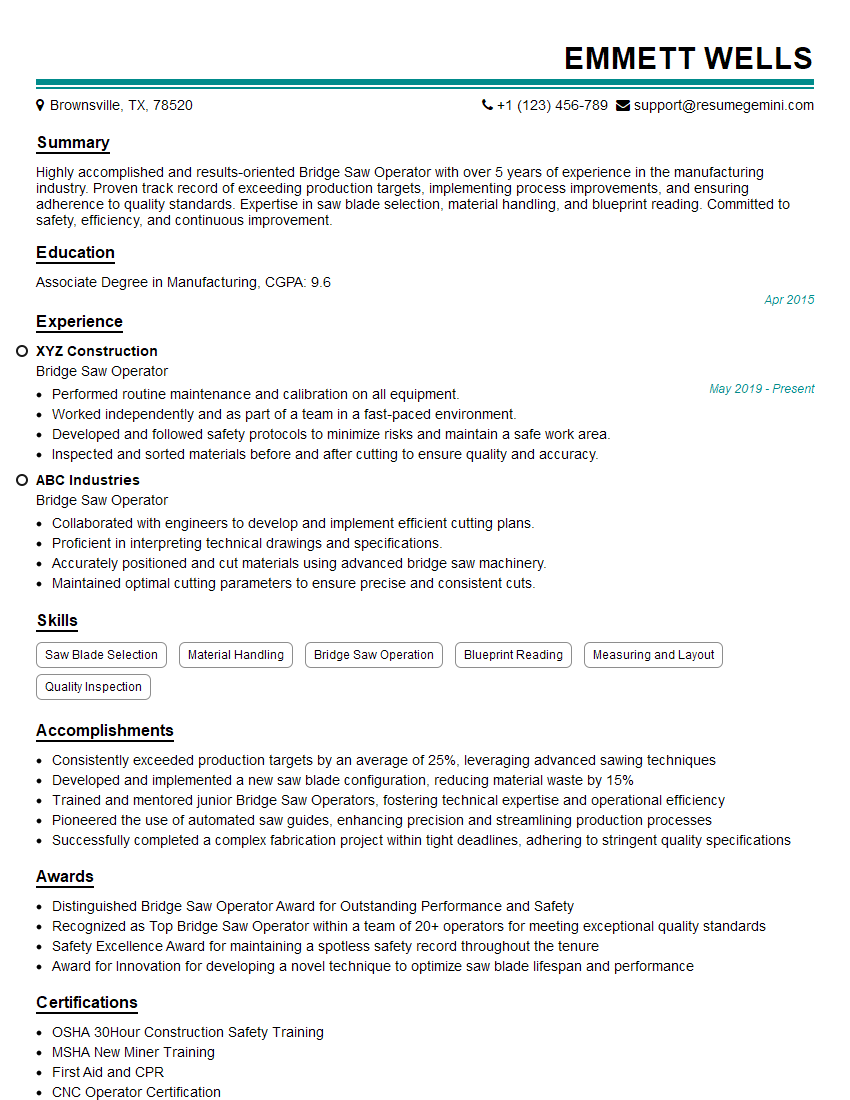

Emmett Wells

Bridge Saw Operator

Summary

Highly accomplished and results-oriented Bridge Saw Operator with over 5 years of experience in the manufacturing industry. Proven track record of exceeding production targets, implementing process improvements, and ensuring adherence to quality standards. Expertise in saw blade selection, material handling, and blueprint reading. Committed to safety, efficiency, and continuous improvement.

Education

Associate Degree in Manufacturing

April 2015

Skills

- Saw Blade Selection

- Material Handling

- Bridge Saw Operation

- Blueprint Reading

- Measuring and Layout

- Quality Inspection

Work Experience

Bridge Saw Operator

- Performed routine maintenance and calibration on all equipment.

- Worked independently and as part of a team in a fast-paced environment.

- Developed and followed safety protocols to minimize risks and maintain a safe work area.

- Inspected and sorted materials before and after cutting to ensure quality and accuracy.

Bridge Saw Operator

- Collaborated with engineers to develop and implement efficient cutting plans.

- Proficient in interpreting technical drawings and specifications.

- Accurately positioned and cut materials using advanced bridge saw machinery.

- Maintained optimal cutting parameters to ensure precise and consistent cuts.

Accomplishments

- Consistently exceeded production targets by an average of 25%, leveraging advanced sawing techniques

- Developed and implemented a new saw blade configuration, reducing material waste by 15%

- Trained and mentored junior Bridge Saw Operators, fostering technical expertise and operational efficiency

- Pioneered the use of automated saw guides, enhancing precision and streamlining production processes

- Successfully completed a complex fabrication project within tight deadlines, adhering to stringent quality specifications

Awards

- Distinguished Bridge Saw Operator Award for Outstanding Performance and Safety

- Recognized as Top Bridge Saw Operator within a team of 20+ operators for meeting exceptional quality standards

- Safety Excellence Award for maintaining a spotless safety record throughout the tenure

- Award for Innovation for developing a novel technique to optimize saw blade lifespan and performance

Certificates

- OSHA 30Hour Construction Safety Training

- MSHA New Miner Training

- First Aid and CPR

- CNC Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bridge Saw Operator

Tips for Writing a Standout Bridge Saw Operator Resume

- 1. Highlight your skills and experience: Emphasize your proficiency in bridge saw operation, saw blade selection, and material handling.

- 2. Quantify your accomplishments: Use specific metrics to demonstrate your impact on production, efficiency, and quality.

- 3. Showcase your commitment to safety: Emphasize your adherence to safety protocols and your role in maintaining a safe work environment.

- 4. Use keywords: Include relevant keywords throughout your resume to increase its visibility to potential employers.

Essential Experience Highlights for a Strong Bridge Saw Operator Resume

- Operate bridge saws to cut and shape materials according to specifications.

- Select and install appropriate saw blades based on material type and desired cut.

- Interpret blueprints and drawings to determine cutting parameters.

- Handle materials safely and efficiently to minimize waste and ensure optimal production.

- Monitor and maintain bridge saws to ensure proper functioning and accuracy.

- Train and supervise junior operators, sharing knowledge and best practices.

- Contribute to process improvement initiatives, identifying areas for optimization.

Frequently Asked Questions (FAQ’s) For Bridge Saw Operator

What are the key skills required for a Bridge Saw Operator?

Bridge Saw Operators typically require proficiency in saw blade selection, material handling, bridge saw operation, blueprint reading, measuring and layout, and quality inspection.

What is the educational background required to become a Bridge Saw Operator?

While formal education is not always required, many Bridge Saw Operators hold an Associate Degree in Manufacturing or a related field.

What are the career prospects for Bridge Saw Operators?

Bridge Saw Operators can advance to roles such as Production Supervisor, Quality Control Inspector, or Maintenance Technician with experience and additional training.

What is the average salary for a Bridge Saw Operator?

The average salary for a Bridge Saw Operator in the United States is around $45,000 per year.

What are the key qualities of a successful Bridge Saw Operator?

Successful Bridge Saw Operators typically possess strong attention to detail, mechanical aptitude, problem-solving skills, and a commitment to safety.

What are the different industries that employ Bridge Saw Operators?

Bridge Saw Operators are employed in various industries, including construction, manufacturing, and woodworking.

What are the safety precautions that Bridge Saw Operators need to follow?

Bridge Saw Operators must adhere to safety protocols such as wearing appropriate personal protective equipment, maintaining a clean and organized work area, and receiving proper training on equipment operation.

What are the common challenges faced by Bridge Saw Operators?

Bridge Saw Operators may encounter challenges such as working with different materials, meeting tight deadlines, and ensuring the accuracy and quality of cuts.