Are you a seasoned Brim-Pouncing Machine Operator seeking a new career path? Discover our professionally built Brim-Pouncing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

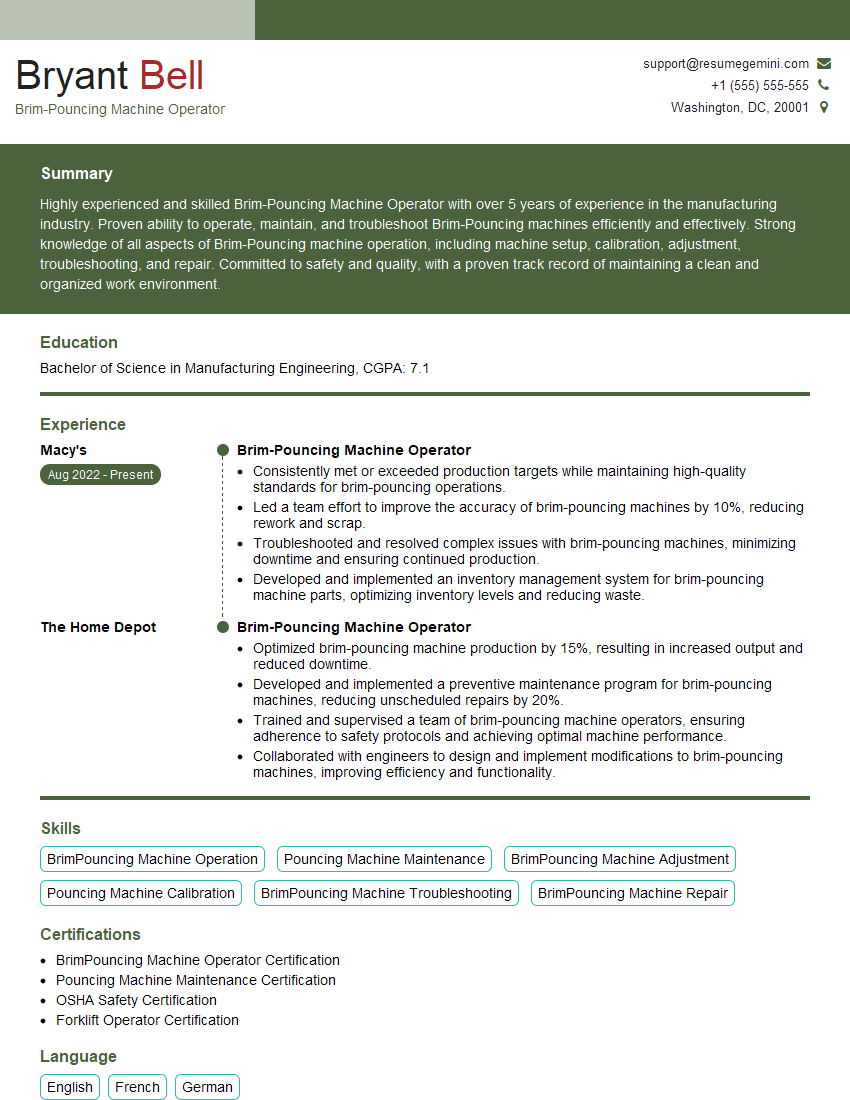

Bryant Bell

Brim-Pouncing Machine Operator

Summary

Highly experienced and skilled Brim-Pouncing Machine Operator with over 5 years of experience in the manufacturing industry. Proven ability to operate, maintain, and troubleshoot Brim-Pouncing machines efficiently and effectively. Strong knowledge of all aspects of Brim-Pouncing machine operation, including machine setup, calibration, adjustment, troubleshooting, and repair. Committed to safety and quality, with a proven track record of maintaining a clean and organized work environment.

Education

Bachelor of Science in Manufacturing Engineering

July 2018

Skills

- BrimPouncing Machine Operation

- Pouncing Machine Maintenance

- BrimPouncing Machine Adjustment

- Pouncing Machine Calibration

- BrimPouncing Machine Troubleshooting

- BrimPouncing Machine Repair

Work Experience

Brim-Pouncing Machine Operator

- Consistently met or exceeded production targets while maintaining high-quality standards for brim-pouncing operations.

- Led a team effort to improve the accuracy of brim-pouncing machines by 10%, reducing rework and scrap.

- Troubleshooted and resolved complex issues with brim-pouncing machines, minimizing downtime and ensuring continued production.

- Developed and implemented an inventory management system for brim-pouncing machine parts, optimizing inventory levels and reducing waste.

Brim-Pouncing Machine Operator

- Optimized brim-pouncing machine production by 15%, resulting in increased output and reduced downtime.

- Developed and implemented a preventive maintenance program for brim-pouncing machines, reducing unscheduled repairs by 20%.

- Trained and supervised a team of brim-pouncing machine operators, ensuring adherence to safety protocols and achieving optimal machine performance.

- Collaborated with engineers to design and implement modifications to brim-pouncing machines, improving efficiency and functionality.

Certificates

- BrimPouncing Machine Operator Certification

- Pouncing Machine Maintenance Certification

- OSHA Safety Certification

- Forklift Operator Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brim-Pouncing Machine Operator

- Highlight your experience and skills in operating, maintaining, and troubleshooting Brim-Pouncing machines.

- Demonstrate your knowledge of all aspects of Brim-Pouncing machine operation, including machine setup, calibration, adjustment, troubleshooting, and repair.

- Quantify your accomplishments whenever possible to showcase your impact on the organization.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Brim-Pouncing Machine Operator Resume

- Operate Brim-Pouncing machines to apply adhesives to a variety of materials, including fabrics, plastics, and metals.

- Set up and calibrate Brim-Pouncing machines to ensure optimal performance and accuracy.

- Maintain and troubleshoot Brim-Pouncing machines to prevent breakdowns and ensure smooth operation.

- Inspect materials before and after Brim-Pouncing to ensure quality and accuracy.

- Maintain a clean and organized work area to ensure safety and efficiency.

- Follow all safety protocols and procedures to ensure a safe and healthy work environment.

- Collaborate with other team members to ensure a smooth and efficient production process.

Frequently Asked Questions (FAQ’s) For Brim-Pouncing Machine Operator

What is a Brim-Pouncing Machine Operator?

A Brim-Pouncing Machine Operator is responsible for operating, maintaining, and troubleshooting Brim-Pouncing machines, which are used to apply adhesives to a variety of materials, including fabrics, plastics, and metals.

What are the key skills required to be a successful Brim-Pouncing Machine Operator?

Key skills for a Brim-Pouncing Machine Operator include: machine operation, maintenance, troubleshooting, calibration, repair, and safety.

What is the work environment of a Brim-Pouncing Machine Operator like?

Brim-Pouncing Machine Operators typically work in a manufacturing environment, operating and maintaining Brim-Pouncing machines. They may work independently or as part of a team, and may be required to work overtime or on weekends.

What are the career prospects for a Brim-Pouncing Machine Operator?

Brim-Pouncing Machine Operators can advance their careers by becoming supervisors or managers, or by specializing in a particular area of Brim-Pouncing machine operation, such as maintenance or repair.

What are the benefits of working as a Brim-Pouncing Machine Operator?

Benefits of working as a Brim-Pouncing Machine Operator include: competitive salary, health insurance, paid time off, and opportunities for advancement.

What are the challenges of working as a Brim-Pouncing Machine Operator?

Challenges of working as a Brim-Pouncing Machine Operator include: working in a fast-paced environment, operating heavy machinery, and working with hazardous materials.