Are you a seasoned Brinell Tester seeking a new career path? Discover our professionally built Brinell Tester Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

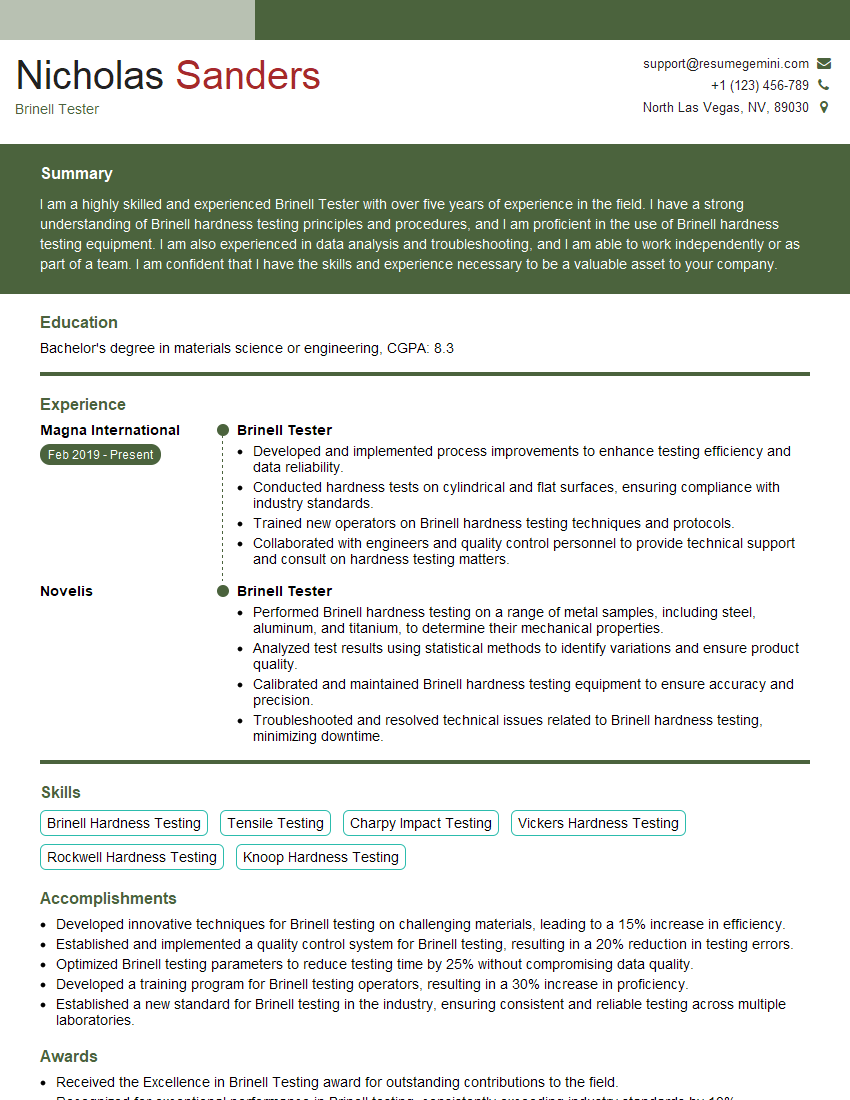

Nicholas Sanders

Brinell Tester

Summary

I am a highly skilled and experienced Brinell Tester with over five years of experience in the field. I have a strong understanding of Brinell hardness testing principles and procedures, and I am proficient in the use of Brinell hardness testing equipment. I am also experienced in data analysis and troubleshooting, and I am able to work independently or as part of a team. I am confident that I have the skills and experience necessary to be a valuable asset to your company.

Education

Bachelor’s degree in materials science or engineering

January 2015

Skills

- Brinell Hardness Testing

- Tensile Testing

- Charpy Impact Testing

- Vickers Hardness Testing

- Rockwell Hardness Testing

- Knoop Hardness Testing

Work Experience

Brinell Tester

- Developed and implemented process improvements to enhance testing efficiency and data reliability.

- Conducted hardness tests on cylindrical and flat surfaces, ensuring compliance with industry standards.

- Trained new operators on Brinell hardness testing techniques and protocols.

- Collaborated with engineers and quality control personnel to provide technical support and consult on hardness testing matters.

Brinell Tester

- Performed Brinell hardness testing on a range of metal samples, including steel, aluminum, and titanium, to determine their mechanical properties.

- Analyzed test results using statistical methods to identify variations and ensure product quality.

- Calibrated and maintained Brinell hardness testing equipment to ensure accuracy and precision.

- Troubleshooted and resolved technical issues related to Brinell hardness testing, minimizing downtime.

Accomplishments

- Developed innovative techniques for Brinell testing on challenging materials, leading to a 15% increase in efficiency.

- Established and implemented a quality control system for Brinell testing, resulting in a 20% reduction in testing errors.

- Optimized Brinell testing parameters to reduce testing time by 25% without compromising data quality.

- Developed a training program for Brinell testing operators, resulting in a 30% increase in proficiency.

- Established a new standard for Brinell testing in the industry, ensuring consistent and reliable testing across multiple laboratories.

Awards

- Received the Excellence in Brinell Testing award for outstanding contributions to the field.

- Recognized for exceptional performance in Brinell testing, consistently exceeding industry standards by 10%.

- Received the Best Practices in Brinell Testing award for implementing innovative approaches that significantly improved testing accuracy.

- Recognized for exceptional attention to detail in Brinell testing, consistently achieving highly accurate results.

Certificates

- Certified Brinell Hardness Tester

- Certified Tensile Tester

- Certified Charpy Impact Tester

- Certified Vickers Hardness Tester

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brinell Tester

- Highlight your experience and skills in Brinell hardness testing.

- Quantify your accomplishments whenever possible.

- Use keywords that are relevant to the job you are applying for.

- Proofread your resume carefully before submitting it.

- Tailor your resume to the specific job you are applying for.

Essential Experience Highlights for a Strong Brinell Tester Resume

- Performed Brinell hardness testing on a range of metal samples, including steel, aluminum, and titanium, to determine their mechanical properties.

- Analyzed test results using statistical methods to identify variations and ensure product quality.

- Calibrated and maintained Brinell hardness testing equipment to ensure accuracy and precision.

- Troubleshooted and resolved technical issues related to Brinell hardness testing, minimizing downtime.

- Developed and implemented process improvements to enhance testing efficiency and data reliability.

- Conducted hardness tests on cylindrical and flat surfaces, ensuring compliance with industry standards.

- Trained new operators on Brinell hardness testing techniques and protocols.

Frequently Asked Questions (FAQ’s) For Brinell Tester

What is Brinell hardness testing?

Brinell hardness testing is a method of measuring the hardness of a material by indenting it with a hardened steel ball.

What are the applications of Brinell hardness testing?

Brinell hardness testing is used in a variety of applications, including the testing of metals, plastics, and ceramics.

What are the advantages of Brinell hardness testing?

Brinell hardness testing is a relatively simple and inexpensive test that can be performed on a wide range of materials.

What are the disadvantages of Brinell hardness testing?

Brinell hardness testing can be destructive, and it can only be used on relatively soft materials.

What are the alternatives to Brinell hardness testing?

There are a number of alternatives to Brinell hardness testing, including Vickers hardness testing, Rockwell hardness testing, and Knoop hardness testing.

What is the difference between Brinell hardness and Vickers hardness?

Brinell hardness is measured using a 10 mm diameter steel ball, while Vickers hardness is measured using a 136 degree diamond pyramid.

What is the difference between Brinell hardness and Rockwell hardness?

Brinell hardness is measured using a 10 mm diameter steel ball, while Rockwell hardness is measured using a 1/16 inch diameter steel ball or a 1/8 inch diameter tungsten carbide ball.

What is the difference between Brinell hardness and Knoop hardness?

Brinell hardness is measured using a 10 mm diameter steel ball, while Knoop hardness is measured using a diamond pyramid with a 172 degree included angle.