Are you a seasoned Briquetter Operator seeking a new career path? Discover our professionally built Briquetter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

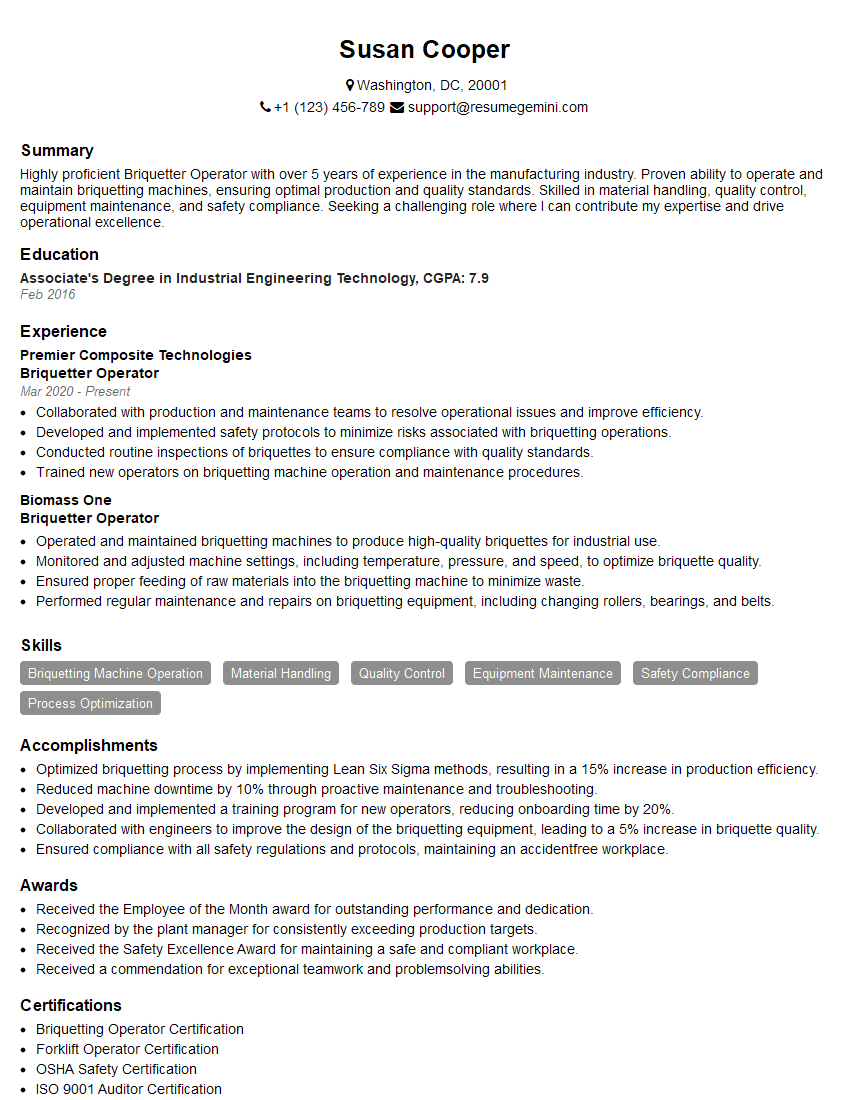

Susan Cooper

Briquetter Operator

Summary

Highly proficient Briquetter Operator with over 5 years of experience in the manufacturing industry. Proven ability to operate and maintain briquetting machines, ensuring optimal production and quality standards. Skilled in material handling, quality control, equipment maintenance, and safety compliance. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate’s Degree in Industrial Engineering Technology

February 2016

Skills

- Briquetting Machine Operation

- Material Handling

- Quality Control

- Equipment Maintenance

- Safety Compliance

- Process Optimization

Work Experience

Briquetter Operator

- Collaborated with production and maintenance teams to resolve operational issues and improve efficiency.

- Developed and implemented safety protocols to minimize risks associated with briquetting operations.

- Conducted routine inspections of briquettes to ensure compliance with quality standards.

- Trained new operators on briquetting machine operation and maintenance procedures.

Briquetter Operator

- Operated and maintained briquetting machines to produce high-quality briquettes for industrial use.

- Monitored and adjusted machine settings, including temperature, pressure, and speed, to optimize briquette quality.

- Ensured proper feeding of raw materials into the briquetting machine to minimize waste.

- Performed regular maintenance and repairs on briquetting equipment, including changing rollers, bearings, and belts.

Accomplishments

- Optimized briquetting process by implementing Lean Six Sigma methods, resulting in a 15% increase in production efficiency.

- Reduced machine downtime by 10% through proactive maintenance and troubleshooting.

- Developed and implemented a training program for new operators, reducing onboarding time by 20%.

- Collaborated with engineers to improve the design of the briquetting equipment, leading to a 5% increase in briquette quality.

- Ensured compliance with all safety regulations and protocols, maintaining an accidentfree workplace.

Awards

- Received the Employee of the Month award for outstanding performance and dedication.

- Recognized by the plant manager for consistently exceeding production targets.

- Received the Safety Excellence Award for maintaining a safe and compliant workplace.

- Received a commendation for exceptional teamwork and problemsolving abilities.

Certificates

- Briquetting Operator Certification

- Forklift Operator Certification

- OSHA Safety Certification

- ISO 9001 Auditor Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Briquetter Operator

- Highlight your technical skills and experience in briquetting machine operation and maintenance.

- Quantify your accomplishments and provide specific examples of how you have contributed to operational efficiency and quality.

- Demonstrate your knowledge of safety regulations and compliance practices.

- Emphasize your ability to work independently and as part of a team in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Briquetter Operator Resume

- Operated briquetting machines to produce briquettes from various materials, including biomass, coal, and minerals.

- Monitored and adjusted process parameters to optimize production efficiency and meet quality specifications.

- Performed routine maintenance and repairs on briquetting machines, including cleaning, lubrication, and troubleshooting.

- Ensured compliance with safety regulations and protocols to maintain a safe working environment.

- Collaborated with production team to improve processes and reduce downtime.

- Conducted quality control inspections to ensure product quality and adherence to customer requirements.

- Maintained accurate records and documentation related to briquetting operations.

Frequently Asked Questions (FAQ’s) For Briquetter Operator

What are the primary duties of a Briquetter Operator?

The primary duties of a Briquetter Operator include operating and maintaining briquetting machines, monitoring production processes, performing quality control inspections, and adhering to safety regulations.

What skills are required to be a successful Briquetter Operator?

Successful Briquetter Operators typically possess skills in briquetting machine operation, material handling, quality control, equipment maintenance, and safety compliance.

What industries employ Briquetter Operators?

Briquetter Operators are employed in various industries, including manufacturing, energy, and recycling.

What is the average salary for a Briquetter Operator?

The average salary for a Briquetter Operator varies depending on experience, location, and industry, but typically ranges from $30,000 to $50,000 per year.

What are the career advancement opportunities for Briquetter Operators?

Briquetter Operators with experience and additional training may advance to roles such as Production Supervisor, Quality Control Manager, or Maintenance Technician.

What are the safety precautions that Briquetter Operators must follow?

Briquetter Operators must follow safety precautions such as wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

What is the work environment like for a Briquetter Operator?

Briquetter Operators typically work in manufacturing facilities or industrial plants, and their work environment may involve exposure to noise, dust, and heavy machinery.