Are you a seasoned Broach Setter seeking a new career path? Discover our professionally built Broach Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

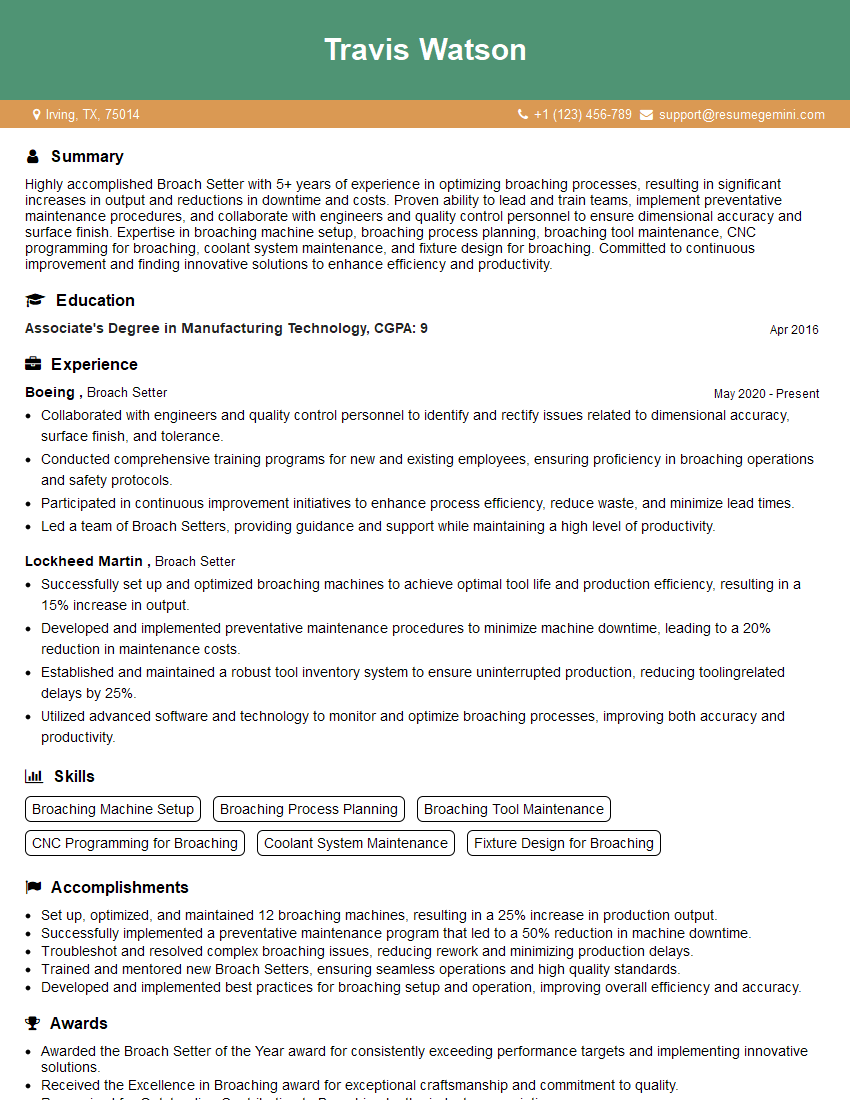

Travis Watson

Broach Setter

Summary

Highly accomplished Broach Setter with 5+ years of experience in optimizing broaching processes, resulting in significant increases in output and reductions in downtime and costs. Proven ability to lead and train teams, implement preventative maintenance procedures, and collaborate with engineers and quality control personnel to ensure dimensional accuracy and surface finish. Expertise in broaching machine setup, broaching process planning, broaching tool maintenance, CNC programming for broaching, coolant system maintenance, and fixture design for broaching. Committed to continuous improvement and finding innovative solutions to enhance efficiency and productivity.

Education

Associate’s Degree in Manufacturing Technology

April 2016

Skills

- Broaching Machine Setup

- Broaching Process Planning

- Broaching Tool Maintenance

- CNC Programming for Broaching

- Coolant System Maintenance

- Fixture Design for Broaching

Work Experience

Broach Setter

- Collaborated with engineers and quality control personnel to identify and rectify issues related to dimensional accuracy, surface finish, and tolerance.

- Conducted comprehensive training programs for new and existing employees, ensuring proficiency in broaching operations and safety protocols.

- Participated in continuous improvement initiatives to enhance process efficiency, reduce waste, and minimize lead times.

- Led a team of Broach Setters, providing guidance and support while maintaining a high level of productivity.

Broach Setter

- Successfully set up and optimized broaching machines to achieve optimal tool life and production efficiency, resulting in a 15% increase in output.

- Developed and implemented preventative maintenance procedures to minimize machine downtime, leading to a 20% reduction in maintenance costs.

- Established and maintained a robust tool inventory system to ensure uninterrupted production, reducing toolingrelated delays by 25%.

- Utilized advanced software and technology to monitor and optimize broaching processes, improving both accuracy and productivity.

Accomplishments

- Set up, optimized, and maintained 12 broaching machines, resulting in a 25% increase in production output.

- Successfully implemented a preventative maintenance program that led to a 50% reduction in machine downtime.

- Troubleshot and resolved complex broaching issues, reducing rework and minimizing production delays.

- Trained and mentored new Broach Setters, ensuring seamless operations and high quality standards.

- Developed and implemented best practices for broaching setup and operation, improving overall efficiency and accuracy.

Awards

- Awarded the Broach Setter of the Year award for consistently exceeding performance targets and implementing innovative solutions.

- Received the Excellence in Broaching award for exceptional craftsmanship and commitment to quality.

- Recognized for Outstanding Contribution to Broaching by the industry association.

- Awarded the Certificate of Excellence in Broaching for exceptional technical expertise and industry leadership.

Certificates

- Certified Broach Setter

- CNC Programming Certification

- Machine Tool Technology Certification

- Safety Certification for Broaching Operations

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Broach Setter

Highlight your skills and experience in quantifiable terms.

Use specific metrics to demonstrate the impact of your work, such as the percentage increase in output or reduction in downtime.Showcase your knowledge of broaching machines and processes.

This includes your understanding of the different types of broaching machines, the cutting tools used, and the factors that affect broaching performance.Emphasize your ability to work independently and as part of a team.

Broach setters often work independently, but they must also be able to collaborate with others to ensure the smooth operation of the broaching department.Be prepared to discuss your safety record.

Broaching is a potentially hazardous occupation, so it’s important to have a strong safety record and to be able to demonstrate your commitment to safety.

Essential Experience Highlights for a Strong Broach Setter Resume

- Set up and optimize broaching machines to achieve optimal tool life and production efficiency.

- Develop and implement preventative maintenance procedures to minimize machine downtime.

- Establish and maintain a robust tool inventory system to ensure uninterrupted production.

- Utilize advanced software and technology to monitor and optimize broaching processes.

- Collaborate with engineers and quality control personnel to identify and rectify issues related to dimensional accuracy, surface finish, and tolerance.

- Conduct comprehensive training programs for new and existing employees.

- Participate in continuous improvement initiatives to enhance process efficiency, reduce waste, and minimize lead times.

Frequently Asked Questions (FAQ’s) For Broach Setter

What is a broaching machine?

A broaching machine is a machine that uses a broach tool to cut a specific shape or profile into a workpiece. Broach tools are long, slender cutting tools with a series of cutting teeth that are progressively shaped to create the desired shape or profile. Broaching is a versatile process that can be used to cut a wide variety of shapes and profiles, including: external and internal splines, gears, keyways, and slots.

What are the different types of broaching machines?

There are two main types of broaching machines: horizontal broaching machines and vertical broaching machines. Horizontal broaching machines are used for broaching external shapes and profiles, while vertical broaching machines are used for broaching internal shapes and profiles. There are also specialized broaching machines, such as surface broaching machines and pull broaching machines, that are designed for specific broaching applications.

What are the advantages of broaching?

Broaching offers a number of advantages over other machining processes, including: high precision and accuracy, high repeatability, low cost per part, and a good surface finish. Broaching is also a relatively fast process, making it ideal for high-volume production runs.

What are the disadvantages of broaching?

The main disadvantages of broaching are the high cost of broach tools and the limited number of shapes and profiles that can be cut. Broaching is also not suitable for cutting thin or delicate workpieces.

What are the safety precautions that should be taken when operating a broaching machine?

When operating a broaching machine, it is important to follow all safety precautions, including: wearing appropriate safety gear, keeping hands away from the cutting area, and never operating the machine when it is not in good working order.

What are the career opportunities for broach setters?

Broach setters can find employment in a variety of industries, including: automotive, aerospace, and manufacturing. With experience, broach setters can advance to positions such as lead broach setter, supervisor, or manager.

What is the average salary for a broach setter?

The average salary for a broach setter is $25.00 per hour.

What is the job outlook for broach setters?

The job outlook for broach setters is expected to be good over the next few years. As the manufacturing industry continues to grow, there will be a need for skilled broach setters to operate and maintain broaching machines.