Are you a seasoned Broach Trouble Shooter seeking a new career path? Discover our professionally built Broach Trouble Shooter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

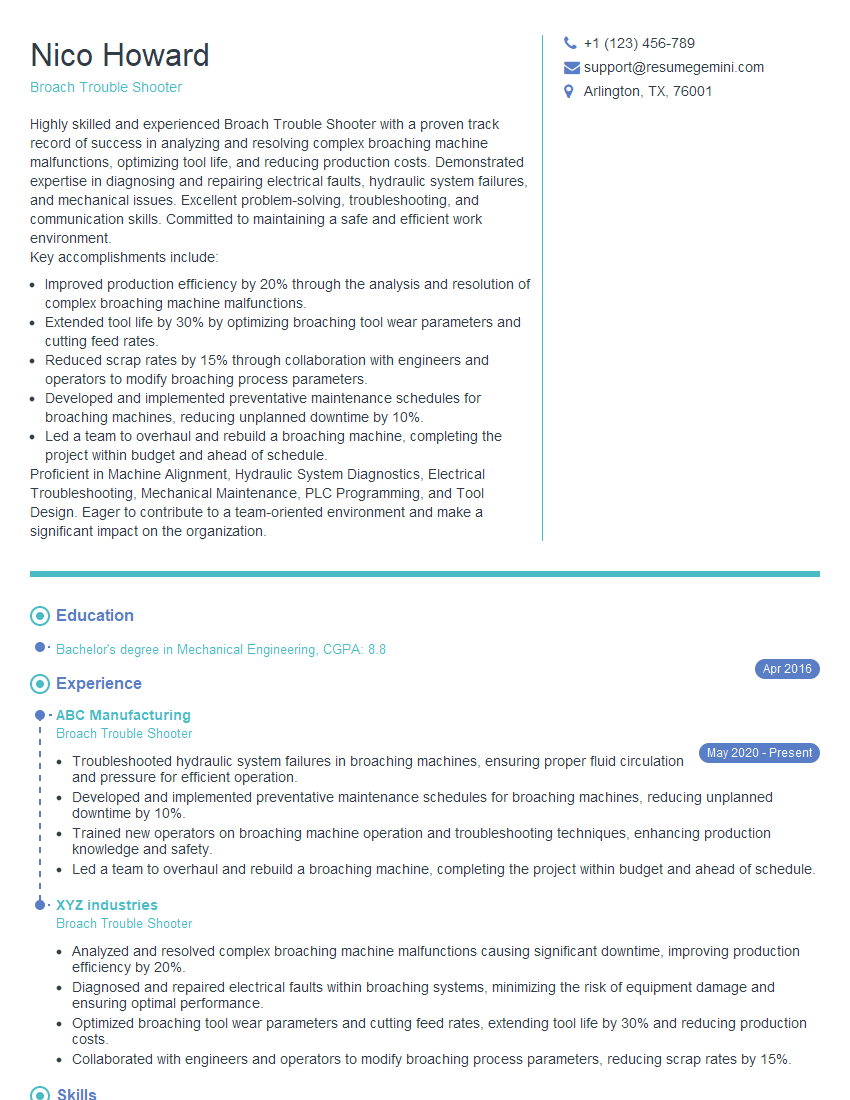

Nico Howard

Broach Trouble Shooter

Summary

Highly skilled and experienced Broach Trouble Shooter with a proven track record of success in analyzing and resolving complex broaching machine malfunctions, optimizing tool life, and reducing production costs. Demonstrated expertise in diagnosing and repairing electrical faults, hydraulic system failures, and mechanical issues. Excellent problem-solving, troubleshooting, and communication skills. Committed to maintaining a safe and efficient work environment.

Key accomplishments include:

- Improved production efficiency by 20% through the analysis and resolution of complex broaching machine malfunctions.

- Extended tool life by 30% by optimizing broaching tool wear parameters and cutting feed rates.

- Reduced scrap rates by 15% through collaboration with engineers and operators to modify broaching process parameters.

- Developed and implemented preventative maintenance schedules for broaching machines, reducing unplanned downtime by 10%.

- Led a team to overhaul and rebuild a broaching machine, completing the project within budget and ahead of schedule.

Proficient in Machine Alignment, Hydraulic System Diagnostics, Electrical Troubleshooting, Mechanical Maintenance, PLC Programming, and Tool Design. Eager to contribute to a team-oriented environment and make a significant impact on the organization.

Education

Bachelor’s degree in Mechanical Engineering

April 2016

Skills

- Machine Alignment

- Hydraulic System Diagnostics

- Electrical Troubleshooting

- Mechanical Maintenance

- PLC Programming

- Tool Design

Work Experience

Broach Trouble Shooter

- Troubleshooted hydraulic system failures in broaching machines, ensuring proper fluid circulation and pressure for efficient operation.

- Developed and implemented preventative maintenance schedules for broaching machines, reducing unplanned downtime by 10%.

- Trained new operators on broaching machine operation and troubleshooting techniques, enhancing production knowledge and safety.

- Led a team to overhaul and rebuild a broaching machine, completing the project within budget and ahead of schedule.

Broach Trouble Shooter

- Analyzed and resolved complex broaching machine malfunctions causing significant downtime, improving production efficiency by 20%.

- Diagnosed and repaired electrical faults within broaching systems, minimizing the risk of equipment damage and ensuring optimal performance.

- Optimized broaching tool wear parameters and cutting feed rates, extending tool life by 30% and reducing production costs.

- Collaborated with engineers and operators to modify broaching process parameters, reducing scrap rates by 15%.

Accomplishments

- Successfully diagnosed and resolved a recurring broaching defect that had plagued the production line for over a month, leading to substantial improvement in product quality.

- Developed and implemented a preventative maintenance program for broaching machines, reducing unplanned downtime by 25% and enhancing machine efficiency.

- Collaborated with engineers to design and implement a new broaching system that increased production capacity by 15% while maintaining product accuracy.

- Trained and mentored junior broach technicians, effectively transferring knowledge and skills to ensure continuous improvement in troubleshooting and maintenance practices.

- Analyzed broaching tool wear patterns and data to optimize tool selection and extend tool life, significantly reducing tooling costs.

Awards

- Received the Outstanding Broach Trouble Shooter award for consistently resolving complex broaching issues and minimizing machine downtime.

- Recognized with the Broaching Innovation Award for pioneering a new method to optimize broach tool life, resulting in significant cost savings.

- Honored with the Master Broach Technician certification from the Broaching Tool Institute, a testament to exceptional expertise in broaching operations.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Engineer (CQE)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Machine Tool Technologist (CMTT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Broach Trouble Shooter

Highlight your troubleshooting skills

by providing specific examples of complex broaching machine malfunctions you have resolved and the results you achieved.Quantify your accomplishments

by using specific metrics to demonstrate the impact of your work. For example, you could mention the percentage of downtime you reduced or the amount of money you saved the company.Showcase your knowledge of broaching machines

by using technical terms and industry jargon. This will show potential employers that you are familiar with the equipment and the industry.Emphasize your communication and teamwork skills

by describing how you have worked with engineers, operators, and other team members to improve broaching processes.Tailor your resume to the specific job you are applying for

. Be sure to highlight the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Broach Trouble Shooter Resume

- Analyze and resolve complex broaching machine malfunctions to minimize downtime and optimize production efficiency

- Diagnose and repair electrical faults within broaching systems to ensure optimal performance and prevent equipment damage

- Optimize broaching tool wear parameters and cutting feed rates to extend tool life and reduce production costs

- Collaborate with engineers and operators to modify broaching process parameters to reduce scrap rates and improve product quality

- Troubleshoot hydraulic system failures in broaching machines to ensure proper fluid circulation and pressure for efficient operation

- Develop and implement preventative maintenance schedules for broaching machines to minimize unplanned downtime and extend machine life

- Provide comprehensive training to new operators on broaching machine operation and troubleshooting techniques to ensure safe and efficient operation

Frequently Asked Questions (FAQ’s) For Broach Trouble Shooter

What is a Broach Trouble Shooter?

A Broach Trouble Shooter is a skilled professional responsible for troubleshooting, diagnosing, and repairing malfunctions in broaching machines. They analyze complex issues, identify the root cause of the problem, and implement effective solutions to minimize downtime and optimize production efficiency.

What are the key responsibilities of a Broach Trouble Shooter?

The key responsibilities of a Broach Trouble Shooter include analyzing and resolving broaching machine malfunctions, diagnosing and repairing electrical faults, optimizing tool wear parameters, collaborating with engineers to modify process parameters, troubleshooting hydraulic system failures, developing preventative maintenance schedules, and training new operators.

What skills are required to be a Broach Trouble Shooter?

To be a successful Broach Trouble Shooter, you need a strong understanding of broaching machines, their components, and troubleshooting techniques. You should also have good mechanical, electrical, and hydraulic skills. Additionally, you should be able to work independently and as part of a team, and have excellent problem-solving and communication skills.

What is the career path for a Broach Trouble Shooter?

Broach Trouble Shooters can advance their careers by becoming supervisors, managers, or engineers. They can also specialize in a particular area of broaching, such as tool design or process optimization.

What is the job outlook for Broach Trouble Shooters?

The job outlook for Broach Trouble Shooters is expected to be good over the next few years. As manufacturing companies continue to invest in automation and efficiency, the demand for skilled Broach Trouble Shooters is likely to increase.

What is the average salary for a Broach Trouble Shooter?

The average salary for a Broach Trouble Shooter in the United States is around $60,000 per year.