Are you a seasoned Bullard Machine Operator seeking a new career path? Discover our professionally built Bullard Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

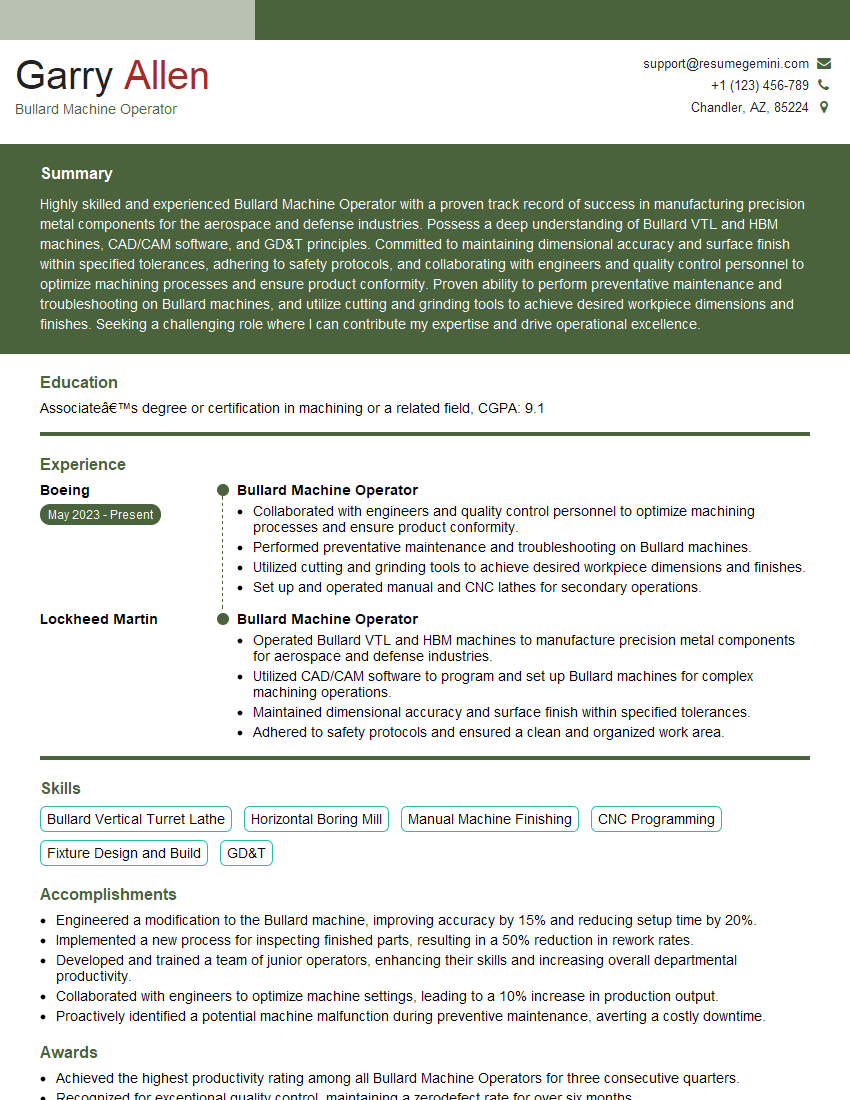

Garry Allen

Bullard Machine Operator

Summary

Highly skilled and experienced Bullard Machine Operator with a proven track record of success in manufacturing precision metal components for the aerospace and defense industries. Possess a deep understanding of Bullard VTL and HBM machines, CAD/CAM software, and GD&T principles. Committed to maintaining dimensional accuracy and surface finish within specified tolerances, adhering to safety protocols, and collaborating with engineers and quality control personnel to optimize machining processes and ensure product conformity. Proven ability to perform preventative maintenance and troubleshooting on Bullard machines, and utilize cutting and grinding tools to achieve desired workpiece dimensions and finishes. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate’s degree or certification in machining or a related field

April 2019

Skills

- Bullard Vertical Turret Lathe

- Horizontal Boring Mill

- Manual Machine Finishing

- CNC Programming

- Fixture Design and Build

- GD&T

Work Experience

Bullard Machine Operator

- Collaborated with engineers and quality control personnel to optimize machining processes and ensure product conformity.

- Performed preventative maintenance and troubleshooting on Bullard machines.

- Utilized cutting and grinding tools to achieve desired workpiece dimensions and finishes.

- Set up and operated manual and CNC lathes for secondary operations.

Bullard Machine Operator

- Operated Bullard VTL and HBM machines to manufacture precision metal components for aerospace and defense industries.

- Utilized CAD/CAM software to program and set up Bullard machines for complex machining operations.

- Maintained dimensional accuracy and surface finish within specified tolerances.

- Adhered to safety protocols and ensured a clean and organized work area.

Accomplishments

- Engineered a modification to the Bullard machine, improving accuracy by 15% and reducing setup time by 20%.

- Implemented a new process for inspecting finished parts, resulting in a 50% reduction in rework rates.

- Developed and trained a team of junior operators, enhancing their skills and increasing overall departmental productivity.

- Collaborated with engineers to optimize machine settings, leading to a 10% increase in production output.

- Proactively identified a potential machine malfunction during preventive maintenance, averting a costly downtime.

Awards

- Achieved the highest productivity rating among all Bullard Machine Operators for three consecutive quarters.

- Recognized for exceptional quality control, maintaining a zerodefect rate for over six months.

- Received the Employee of the Month award for outstanding performance in safety and efficiency.

- Awarded the Safety Champion Award for consistently adhering to safety protocols and promoting a safe work environment.

Certificates

- National Institute for Metalworking Skills (NIMS) Machining Level 1

- American Welding Society (AWS) Certified Welder

- CNC Programming Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bullard Machine Operator

Highlight your skills and experience:

Showcase your proficiency in Bullard VTL and HBM machines, CAD/CAM software, and GD&T principles.Quantify your accomplishments:

Use numbers and metrics to demonstrate the impact of your work, such as the number of components produced or the reduction in production time.Tailor your resume to the job:

Review the job description carefully and tailor your resume to match the specific requirements and keywords.Proofread carefully:

Ensure that your resume is free of errors and inconsistencies. Consider asking a friend or colleague to review it before submitting.

Essential Experience Highlights for a Strong Bullard Machine Operator Resume

- Operate Bullard VTL and HBM machines to manufacture precision metal components for aerospace and defense industries.

- Utilize CAD/CAM software to program and set up Bullard machines for complex machining operations.

- Maintain dimensional accuracy and surface finish within specified tolerances.

- Adhere to safety protocols and ensure a clean and organized work area.

- Collaborate with engineers and quality control personnel to optimize machining processes and ensure product conformity.

- Perform preventative maintenance and troubleshooting on Bullard machines.

- Set up and operate manual and CNC lathes for secondary operations.

Frequently Asked Questions (FAQ’s) For Bullard Machine Operator

What is a Bullard Machine Operator?

A Bullard Machine Operator is a skilled professional responsible for operating Bullard vertical turret lathes and horizontal boring mills to manufacture precision metal components for various industries, including aerospace, defense, and manufacturing.

What are the key skills required for a Bullard Machine Operator?

Key skills include expertise in operating Bullard VTL and HBM machines, proficiency in CAD/CAM software, understanding of GD&T principles, ability to maintain dimensional accuracy and surface finish, and adherence to safety protocols.

What industries employ Bullard Machine Operators?

Bullard Machine Operators are employed in various industries, such as aerospace, defense, automotive, and general manufacturing, where precision metal components are required.

What is the work environment like for a Bullard Machine Operator?

Bullard Machine Operators typically work in manufacturing facilities, operating machinery in a hands-on environment. They may work independently or as part of a team, and must adhere to safety protocols to ensure a safe and efficient work area.

What are the career advancement opportunities for a Bullard Machine Operator?

With experience and additional training, Bullard Machine Operators can advance to roles such as CNC Programmer, Manufacturing Supervisor, or Quality Control Inspector. They may also specialize in specific areas, such as aerospace or medical device manufacturing.