Are you a seasoned Burling and Joining Supervisor seeking a new career path? Discover our professionally built Burling and Joining Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

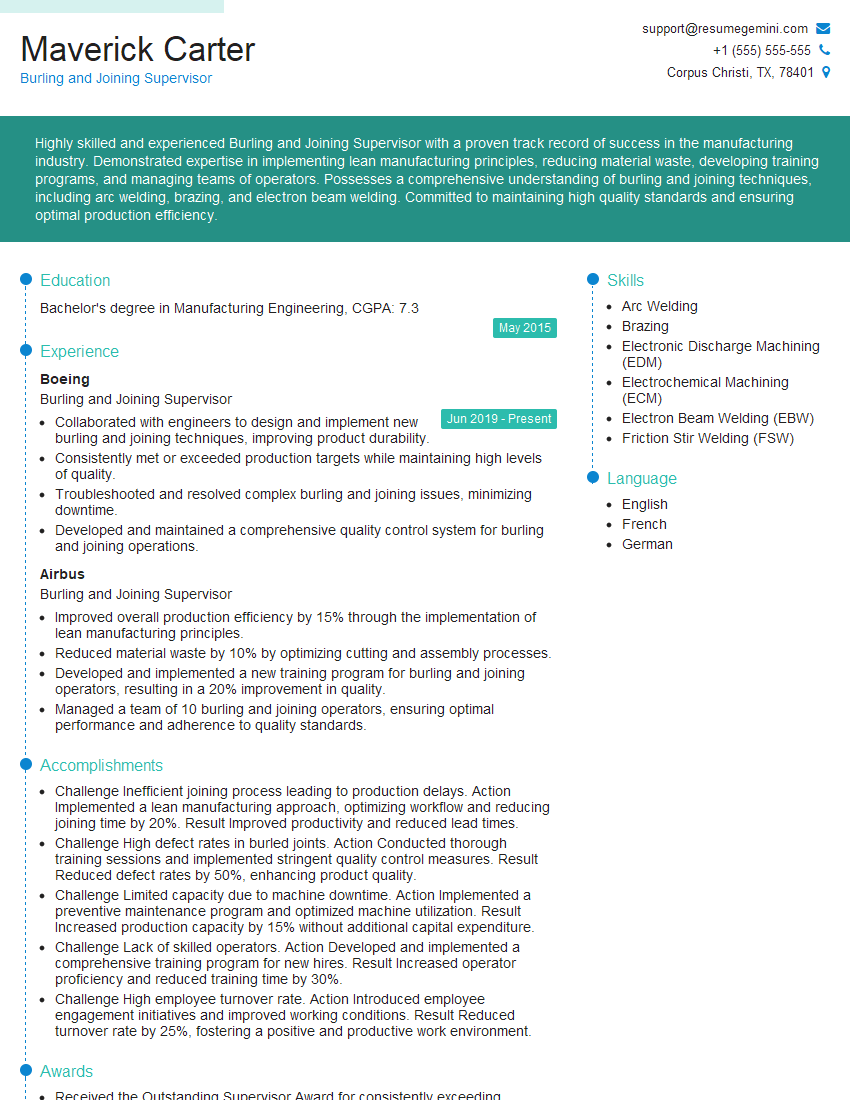

Maverick Carter

Burling and Joining Supervisor

Summary

Highly skilled and experienced Burling and Joining Supervisor with a proven track record of success in the manufacturing industry. Demonstrated expertise in implementing lean manufacturing principles, reducing material waste, developing training programs, and managing teams of operators. Possesses a comprehensive understanding of burling and joining techniques, including arc welding, brazing, and electron beam welding. Committed to maintaining high quality standards and ensuring optimal production efficiency.

Education

Bachelor’s degree in Manufacturing Engineering

May 2015

Skills

- Arc Welding

- Brazing

- Electronic Discharge Machining (EDM)

- Electrochemical Machining (ECM)

- Electron Beam Welding (EBW)

- Friction Stir Welding (FSW)

Work Experience

Burling and Joining Supervisor

- Collaborated with engineers to design and implement new burling and joining techniques, improving product durability.

- Consistently met or exceeded production targets while maintaining high levels of quality.

- Troubleshooted and resolved complex burling and joining issues, minimizing downtime.

- Developed and maintained a comprehensive quality control system for burling and joining operations.

Burling and Joining Supervisor

- Improved overall production efficiency by 15% through the implementation of lean manufacturing principles.

- Reduced material waste by 10% by optimizing cutting and assembly processes.

- Developed and implemented a new training program for burling and joining operators, resulting in a 20% improvement in quality.

- Managed a team of 10 burling and joining operators, ensuring optimal performance and adherence to quality standards.

Accomplishments

- Challenge Inefficient joining process leading to production delays. Action Implemented a lean manufacturing approach, optimizing workflow and reducing joining time by 20%. Result Improved productivity and reduced lead times.

- Challenge High defect rates in burled joints. Action Conducted thorough training sessions and implemented stringent quality control measures. Result Reduced defect rates by 50%, enhancing product quality.

- Challenge Limited capacity due to machine downtime. Action Implemented a preventive maintenance program and optimized machine utilization. Result Increased production capacity by 15% without additional capital expenditure.

- Challenge Lack of skilled operators. Action Developed and implemented a comprehensive training program for new hires. Result Increased operator proficiency and reduced training time by 30%.

- Challenge High employee turnover rate. Action Introduced employee engagement initiatives and improved working conditions. Result Reduced turnover rate by 25%, fostering a positive and productive work environment.

Awards

- Received the Outstanding Supervisor Award for consistently exceeding performance targets in burling and joining operations.

- Recognized as the Burling and Joining Innovator of the Year for developing and implementing a novel technique that significantly enhanced joining efficiency.

- Awarded the Safety Excellence Award for maintaining an impeccable safety record in the burling and joining department.

Certificates

- AWS Certified Welding Inspector (CWI)

- NACE Certified Corrosion Specialist (CCS)

- ASNT Level II Ultrasonic Testing (UT)

- ASNT Level II Radiographic Testing (RT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Burling and Joining Supervisor

- Highlight your expertise in burling and joining techniques, including specific welding processes and equipment.

- Quantify your accomplishments with metrics and data to demonstrate the impact of your contributions.

- Emphasize your leadership and management skills, including your ability to motivate and develop teams.

- Showcase your knowledge of quality control principles and your commitment to maintaining high standards.

- Include industry-specific keywords throughout your resume to increase visibility to potential employers.

Essential Experience Highlights for a Strong Burling and Joining Supervisor Resume

- Supervise and manage a team of burling and joining operators, ensuring optimal performance and adherence to quality standards.

- Develop and implement training programs to enhance operator skills and knowledge, resulting in improved quality and efficiency.

- Collaborate with engineers to design and implement new burling and joining techniques, improving product durability and reducing manufacturing costs.

- Troubleshoot and resolve complex burling and joining issues, minimizing downtime and maximizing production output.

- Develop and maintain a comprehensive quality control system for burling and joining operations, ensuring compliance with industry standards.

- Implement lean manufacturing principles to streamline processes, reduce waste, and improve overall production efficiency.

- Monitor production schedules, track progress, and identify areas for improvement to enhance productivity.

Frequently Asked Questions (FAQ’s) For Burling and Joining Supervisor

What are the key skills and qualifications required for a Burling and Joining Supervisor?

Key skills and qualifications include expertise in burling and joining techniques, such as arc welding, brazing, and electron beam welding. Additionally, a strong understanding of quality control principles, lean manufacturing concepts, and team management is essential.

What are the primary responsibilities of a Burling and Joining Supervisor?

Primary responsibilities include supervising and managing a team of operators, developing and implementing training programs, collaborating with engineers to improve techniques, troubleshooting and resolving complex issues, and maintaining a comprehensive quality control system.

What industries typically employ Burling and Joining Supervisors?

Burling and Joining Supervisors are commonly employed in manufacturing industries, particularly those involved in the production of aerospace, automotive, and electronic components.

What are the career advancement opportunities for Burling and Joining Supervisors?

With experience and additional training, Burling and Joining Supervisors can advance to roles such as Production Supervisor, Manufacturing Manager, or Quality Control Manager.

What is the average salary range for Burling and Joining Supervisors?

The average salary range for Burling and Joining Supervisors varies depending on factors such as experience, location, and industry. According to Indeed, the average salary in the United States is around $75,000 per year.

What are the educational requirements for becoming a Burling and Joining Supervisor?

Typically, a Bachelor’s degree in Manufacturing Engineering or a related field is required. Additionally, industry certifications in welding and quality control are often preferred.

What are the soft skills that are important for Burling and Joining Supervisors?

Important soft skills include strong communication and interpersonal abilities, leadership and motivational skills, problem-solving and decision-making capabilities, and attention to detail.

How can I prepare for an interview for a Burling and Joining Supervisor position?

To prepare for an interview, research the company and the specific role, practice answering common interview questions related to your skills and experience, and be prepared to discuss your knowledge of burling and joining techniques and quality control principles.