Are you a seasoned C D Still Operator seeking a new career path? Discover our professionally built C D Still Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

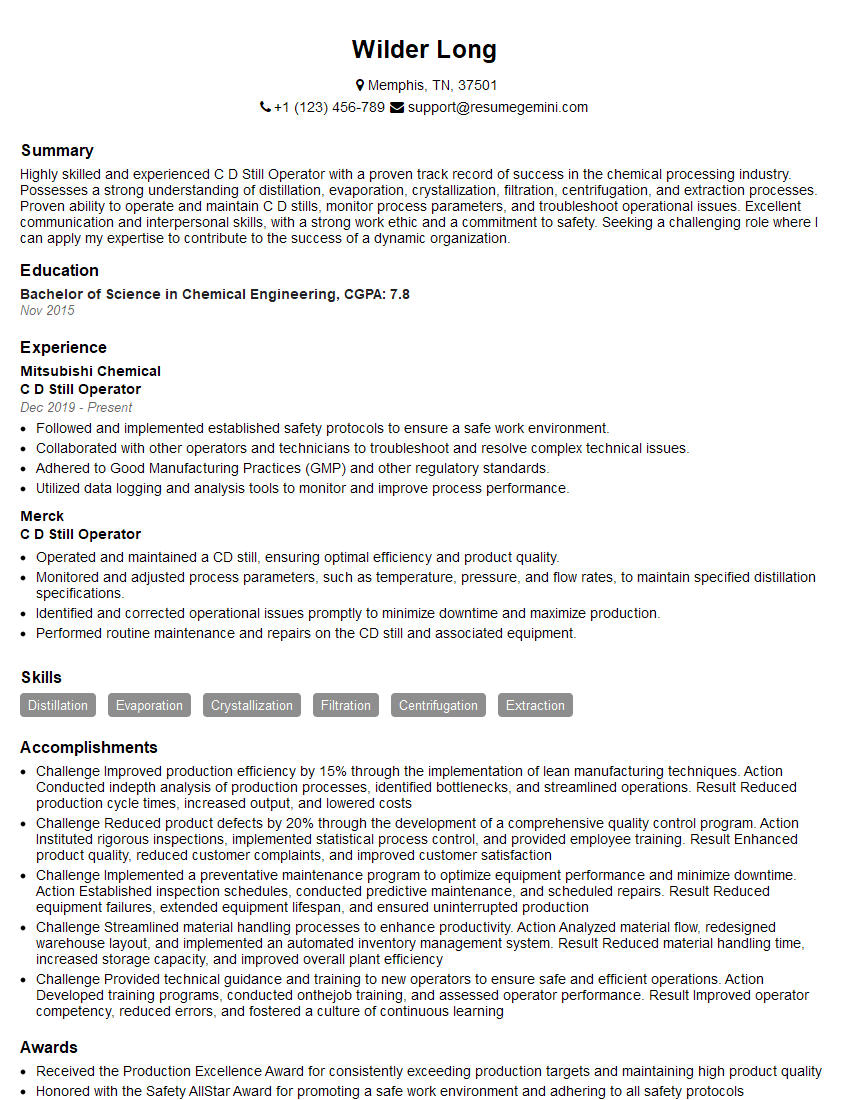

Wilder Long

C D Still Operator

Summary

Highly skilled and experienced C D Still Operator with a proven track record of success in the chemical processing industry. Possesses a strong understanding of distillation, evaporation, crystallization, filtration, centrifugation, and extraction processes. Proven ability to operate and maintain C D stills, monitor process parameters, and troubleshoot operational issues. Excellent communication and interpersonal skills, with a strong work ethic and a commitment to safety. Seeking a challenging role where I can apply my expertise to contribute to the success of a dynamic organization.

Education

Bachelor of Science in Chemical Engineering

November 2015

Skills

- Distillation

- Evaporation

- Crystallization

- Filtration

- Centrifugation

- Extraction

Work Experience

C D Still Operator

- Followed and implemented established safety protocols to ensure a safe work environment.

- Collaborated with other operators and technicians to troubleshoot and resolve complex technical issues.

- Adhered to Good Manufacturing Practices (GMP) and other regulatory standards.

- Utilized data logging and analysis tools to monitor and improve process performance.

C D Still Operator

- Operated and maintained a CD still, ensuring optimal efficiency and product quality.

- Monitored and adjusted process parameters, such as temperature, pressure, and flow rates, to maintain specified distillation specifications.

- Identified and corrected operational issues promptly to minimize downtime and maximize production.

- Performed routine maintenance and repairs on the CD still and associated equipment.

Accomplishments

- Challenge Improved production efficiency by 15% through the implementation of lean manufacturing techniques. Action Conducted indepth analysis of production processes, identified bottlenecks, and streamlined operations. Result Reduced production cycle times, increased output, and lowered costs

- Challenge Reduced product defects by 20% through the development of a comprehensive quality control program. Action Instituted rigorous inspections, implemented statistical process control, and provided employee training. Result Enhanced product quality, reduced customer complaints, and improved customer satisfaction

- Challenge Implemented a preventative maintenance program to optimize equipment performance and minimize downtime. Action Established inspection schedules, conducted predictive maintenance, and scheduled repairs. Result Reduced equipment failures, extended equipment lifespan, and ensured uninterrupted production

- Challenge Streamlined material handling processes to enhance productivity. Action Analyzed material flow, redesigned warehouse layout, and implemented an automated inventory management system. Result Reduced material handling time, increased storage capacity, and improved overall plant efficiency

- Challenge Provided technical guidance and training to new operators to ensure safe and efficient operations. Action Developed training programs, conducted onthejob training, and assessed operator performance. Result Improved operator competency, reduced errors, and fostered a culture of continuous learning

Awards

- Received the Production Excellence Award for consistently exceeding production targets and maintaining high product quality

- Honored with the Safety AllStar Award for promoting a safe work environment and adhering to all safety protocols

- Recognized with the Team Player of the Year Award for exceptional collaboration and problemsolving skills

- Acknowledged with the Excellence in Training Award for exceptional contributions to operator development and skills enhancement

Certificates

- Certified Distillation Operator

- Certified Evaporation Operator

- Certified Crystallization Operator

- Certified Filtration Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For C D Still Operator

- Tailor your resume to each specific job posting, highlighting the skills and experience that are most relevant to the position.

- Use keywords from the job posting in your resume, as this will help your resume get noticed by applicant tracking systems.

- Proofread your resume carefully for any errors in grammar or spelling.

- Get feedback on your resume from a career counselor or recruiter.

Essential Experience Highlights for a Strong C D Still Operator Resume

- Operate and maintain C D stills to produce high-quality chemicals and solvents.

- Monitor process parameters, adjust controls, and troubleshoot operational issues to ensure efficient and safe operation.

- Perform routine maintenance and repairs on C D stills and associated equipment.

- Develop and implement process improvements to optimize production and reduce costs.

- Comply with all safety regulations and procedures, and maintain a clean and organized work environment.

- Train and supervise new operators, and provide guidance to other team members.

- Contribute to the development and implementation of new processes and technologies.

Frequently Asked Questions (FAQ’s) For C D Still Operator

What is the role of a C D Still Operator?

A C D Still Operator is responsible for operating and maintaining C D stills, which are used to separate and purify chemicals and solvents through distillation, evaporation, crystallization, filtration, centrifugation, and extraction processes.

What are the key skills required to be a successful C D Still Operator?

Key skills for a C D Still Operator include a strong understanding of chemical processing principles, experience in operating and maintaining C D stills, and proficiency in troubleshooting operational issues.

What are the career prospects for a C D Still Operator?

C D Still Operators can advance their careers by becoming supervisors, process engineers, or plant managers. They may also specialize in a particular area of chemical processing, such as distillation or extraction.

What is the average salary for a C D Still Operator?

The average salary for a C D Still Operator in the United States is around $60,000 per year.

What are the working conditions for a C D Still Operator?

C D Still Operators typically work in industrial settings, such as chemical plants or refineries. They may work indoors or outdoors, and may be exposed to hazardous chemicals and noise.

What is the job outlook for a C D Still Operator?

The job outlook for C D Still Operators is expected to be good over the next several years, as there is a growing demand for chemicals and solvents in various industries.