Are you a seasoned Calender Supervisor seeking a new career path? Discover our professionally built Calender Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

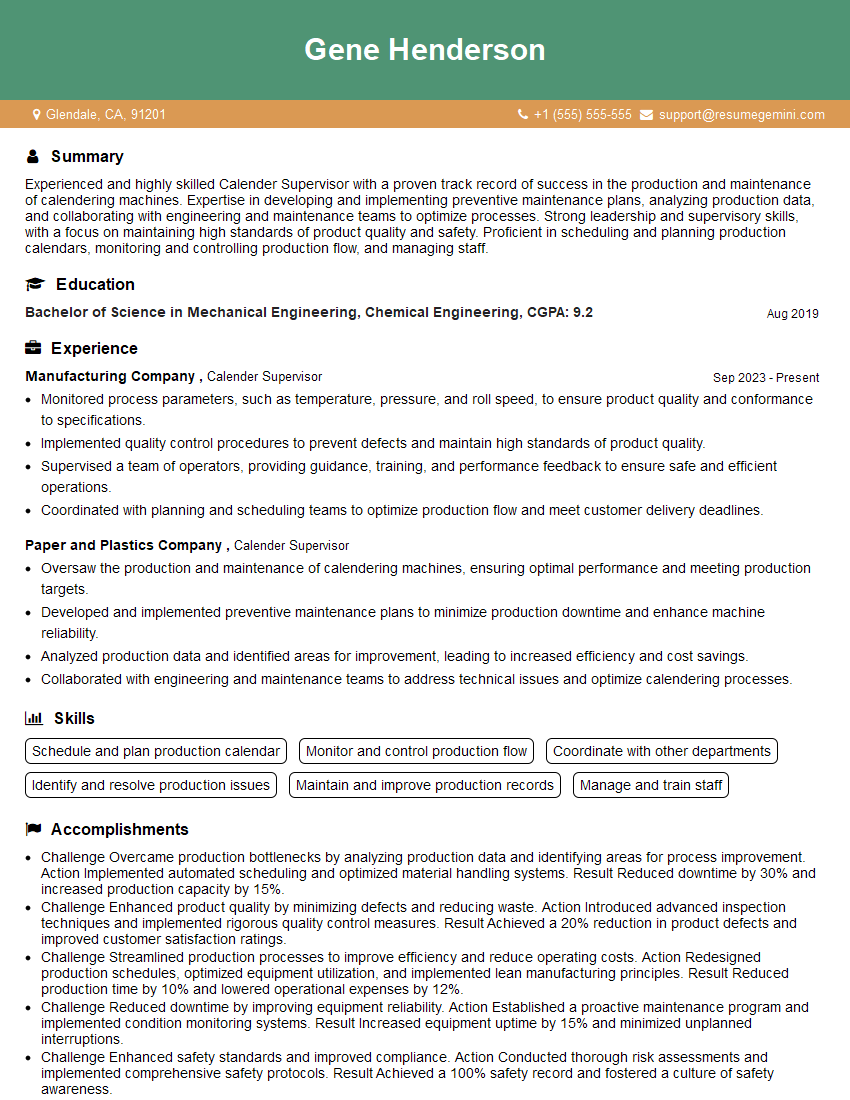

Gene Henderson

Calender Supervisor

Summary

Experienced and highly skilled Calender Supervisor with a proven track record of success in the production and maintenance of calendering machines. Expertise in developing and implementing preventive maintenance plans, analyzing production data, and collaborating with engineering and maintenance teams to optimize processes. Strong leadership and supervisory skills, with a focus on maintaining high standards of product quality and safety. Proficient in scheduling and planning production calendars, monitoring and controlling production flow, and managing staff.

Education

Bachelor of Science in Mechanical Engineering, Chemical Engineering

August 2019

Skills

- Schedule and plan production calendar

- Monitor and control production flow

- Coordinate with other departments

- Identify and resolve production issues

- Maintain and improve production records

- Manage and train staff

Work Experience

Calender Supervisor

- Monitored process parameters, such as temperature, pressure, and roll speed, to ensure product quality and conformance to specifications.

- Implemented quality control procedures to prevent defects and maintain high standards of product quality.

- Supervised a team of operators, providing guidance, training, and performance feedback to ensure safe and efficient operations.

- Coordinated with planning and scheduling teams to optimize production flow and meet customer delivery deadlines.

Calender Supervisor

- Oversaw the production and maintenance of calendering machines, ensuring optimal performance and meeting production targets.

- Developed and implemented preventive maintenance plans to minimize production downtime and enhance machine reliability.

- Analyzed production data and identified areas for improvement, leading to increased efficiency and cost savings.

- Collaborated with engineering and maintenance teams to address technical issues and optimize calendering processes.

Accomplishments

- Challenge Overcame production bottlenecks by analyzing production data and identifying areas for process improvement. Action Implemented automated scheduling and optimized material handling systems. Result Reduced downtime by 30% and increased production capacity by 15%.

- Challenge Enhanced product quality by minimizing defects and reducing waste. Action Introduced advanced inspection techniques and implemented rigorous quality control measures. Result Achieved a 20% reduction in product defects and improved customer satisfaction ratings.

- Challenge Streamlined production processes to improve efficiency and reduce operating costs. Action Redesigned production schedules, optimized equipment utilization, and implemented lean manufacturing principles. Result Reduced production time by 10% and lowered operational expenses by 12%.

- Challenge Reduced downtime by improving equipment reliability. Action Established a proactive maintenance program and implemented condition monitoring systems. Result Increased equipment uptime by 15% and minimized unplanned interruptions.

- Challenge Enhanced safety standards and improved compliance. Action Conducted thorough risk assessments and implemented comprehensive safety protocols. Result Achieved a 100% safety record and fostered a culture of safety awareness.

Awards

- Received the Calender Supervisor of the Year award for consistently exceeding performance targets and driving operational efficiency.

- Awarded the Excellence in Calender Operations plaque for implementing innovative techniques that improved production yield by 25%.

- Recognized with the Exceptional Leadership Award for fostering a highperforming team and maintaining a safe and productive work environment.

- Honored with the Innovation in Calender Supervision award for developing and implementing a new calendering technique that significantly improved product quality.

Certificates

- Certified Production Scheduler (CPS)

- Certified Production Supervisor (CPSup)

- Lean Production Certification

- Quality Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Calender Supervisor

- Highlight your technical skills in calendering machine operation and maintenance.

- Quantify your accomplishments using specific metrics and data whenever possible.

- Demonstrate your leadership and supervisory experience, including any performance management or team development initiatives.

- Showcase your knowledge of quality control procedures and your commitment to maintaining high standards.

Essential Experience Highlights for a Strong Calender Supervisor Resume

- Oversaw the production and maintenance of calendering machines, ensuring optimal performance and meeting production targets.

- Developed and implemented preventive maintenance plans to minimize production downtime and enhance machine reliability.

- Analyzed production data and identified areas for improvement, leading to increased efficiency and cost savings.

- Collaborated with engineering and maintenance teams to address technical issues and optimize calendering processes.

- Supervised a team of operators, providing guidance, training, and performance feedback to ensure safe and efficient operations.

- Coordinated with planning and scheduling teams to optimize production flow and meet customer delivery deadlines.

- Monitored process parameters, such as temperature, pressure, and roll speed, to ensure product quality and conformance to specifications.

Frequently Asked Questions (FAQ’s) For Calender Supervisor

What are the key responsibilities of a Calender Supervisor?

The key responsibilities of a Calender Supervisor include overseeing production and maintenance of calendering machines, developing preventive maintenance plans, analyzing production data, collaborating with engineering and maintenance teams, supervising operators, coordinating with planning and scheduling teams, and monitoring process parameters.

What skills are required to be a successful Calender Supervisor?

To be a successful Calender Supervisor, you need technical skills in calendering machine operation and maintenance, problem-solving, analytical thinking, leadership, and communication.

What is the career path for a Calender Supervisor?

The career path for a Calender Supervisor can lead to roles such as Production Manager, Plant Manager, or Quality Assurance Manager.

What is the salary range for a Calender Supervisor?

The salary range for a Calender Supervisor varies depending on experience, location, and company size, but generally falls between $60,000 to $100,000 per year.

What are the challenges of being a Calender Supervisor?

The challenges of being a Calender Supervisor include managing a team of operators, ensuring production targets are met, and maintaining high standards of product quality while adhering to safety regulations.

What are the benefits of being a Calender Supervisor?

The benefits of being a Calender Supervisor include a competitive salary, opportunities for career advancement, and the satisfaction of working in a challenging and rewarding field.