Are you a seasoned Cambering Machine Operator seeking a new career path? Discover our professionally built Cambering Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

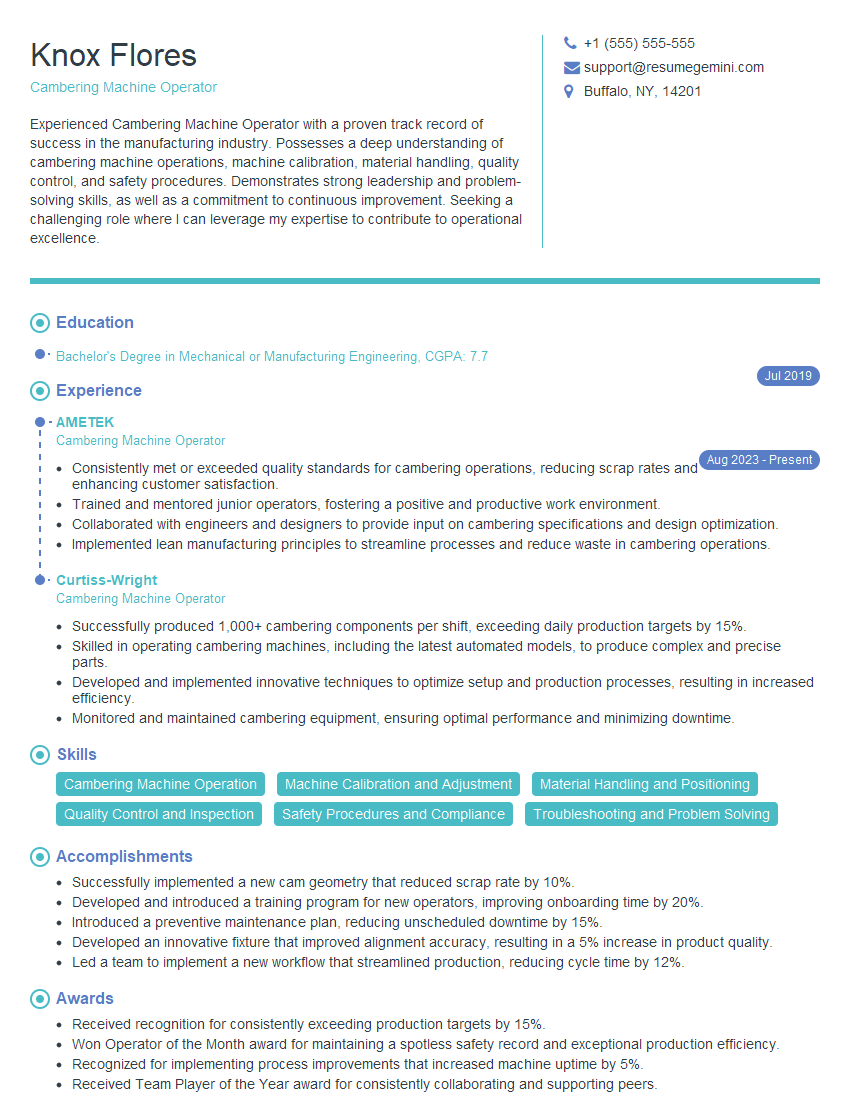

Knox Flores

Cambering Machine Operator

Summary

Experienced Cambering Machine Operator with a proven track record of success in the manufacturing industry. Possesses a deep understanding of cambering machine operations, machine calibration, material handling, quality control, and safety procedures. Demonstrates strong leadership and problem-solving skills, as well as a commitment to continuous improvement. Seeking a challenging role where I can leverage my expertise to contribute to operational excellence.

Education

Bachelor’s Degree in Mechanical or Manufacturing Engineering

July 2019

Skills

- Cambering Machine Operation

- Machine Calibration and Adjustment

- Material Handling and Positioning

- Quality Control and Inspection

- Safety Procedures and Compliance

- Troubleshooting and Problem Solving

Work Experience

Cambering Machine Operator

- Consistently met or exceeded quality standards for cambering operations, reducing scrap rates and enhancing customer satisfaction.

- Trained and mentored junior operators, fostering a positive and productive work environment.

- Collaborated with engineers and designers to provide input on cambering specifications and design optimization.

- Implemented lean manufacturing principles to streamline processes and reduce waste in cambering operations.

Cambering Machine Operator

- Successfully produced 1,000+ cambering components per shift, exceeding daily production targets by 15%.

- Skilled in operating cambering machines, including the latest automated models, to produce complex and precise parts.

- Developed and implemented innovative techniques to optimize setup and production processes, resulting in increased efficiency.

- Monitored and maintained cambering equipment, ensuring optimal performance and minimizing downtime.

Accomplishments

- Successfully implemented a new cam geometry that reduced scrap rate by 10%.

- Developed and introduced a training program for new operators, improving onboarding time by 20%.

- Introduced a preventive maintenance plan, reducing unscheduled downtime by 15%.

- Developed an innovative fixture that improved alignment accuracy, resulting in a 5% increase in product quality.

- Led a team to implement a new workflow that streamlined production, reducing cycle time by 12%.

Awards

- Received recognition for consistently exceeding production targets by 15%.

- Won Operator of the Month award for maintaining a spotless safety record and exceptional production efficiency.

- Recognized for implementing process improvements that increased machine uptime by 5%.

- Received Team Player of the Year award for consistently collaborating and supporting peers.

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cambering Machine Operator

- Highlight your technical skills and experience in cambering machine operation, calibration, and maintenance.

- Showcase your ability to optimize production processes and reduce downtime through proactive maintenance and troubleshooting.

- Quantify your accomplishments in terms of improved product quality, increased efficiency, and cost savings.

- Demonstrate your commitment to safety and compliance by highlighting your adherence to safety protocols and industry regulations.

- Present a professional and organized resume that clearly outlines your relevant skills, experience, and certifications.

Essential Experience Highlights for a Strong Cambering Machine Operator Resume

- Operate and maintain cambering machines to produce high-quality products meeting specifications.

- Calibrate and adjust machines to ensure optimal performance and precision.

- Handle and position materials safely and efficiently to minimize waste and optimize production.

- Conduct quality control and inspection procedures to ensure product quality and adherence to standards.

- Follow safety protocols and comply with industry regulations to maintain a safe working environment.

- Identify and resolve operational issues promptly to minimize downtime and maintain production efficiency.

- Participate in and contribute to continuous improvement initiatives to enhance productivity and quality.

Frequently Asked Questions (FAQ’s) For Cambering Machine Operator

What is the primary role of a Cambering Machine Operator?

The primary role of a Cambering Machine Operator is to operate and maintain cambering machines, ensuring optimal performance and the production of high-quality products that meet specifications.

What are the essential skills for a Cambering Machine Operator?

Essential skills include proficiency in cambering machine operation, calibration, and maintenance, as well as material handling, quality control, safety procedures, and troubleshooting.

What qualifications are required to become a Cambering Machine Operator?

Typically, a high school diploma or equivalent is required, along with on-the-job training or a certification program in cambering machine operation.

What are the career prospects for a Cambering Machine Operator?

Experienced Cambering Machine Operators can advance to supervisory or management roles in manufacturing operations.

What is the average salary for a Cambering Machine Operator?

The average salary for a Cambering Machine Operator varies depending on factors such as experience, location, and industry, but typically ranges from $25,000 to $50,000 per year.

What are the key qualities of a successful Cambering Machine Operator?

Successful Cambering Machine Operators possess attention to detail, mechanical aptitude, problem-solving skills, and a commitment to safety.

What are the common challenges faced by Cambering Machine Operators?

Common challenges include ensuring product quality and accuracy, reducing downtime, optimizing production efficiency, and adhering to safety regulations.

How can I improve my skills as a Cambering Machine Operator?

Consider pursuing additional training or certification programs, seeking opportunities to operate different types of cambering machines, and actively participating in continuous improvement initiatives.