Are you a seasoned Can Capper seeking a new career path? Discover our professionally built Can Capper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

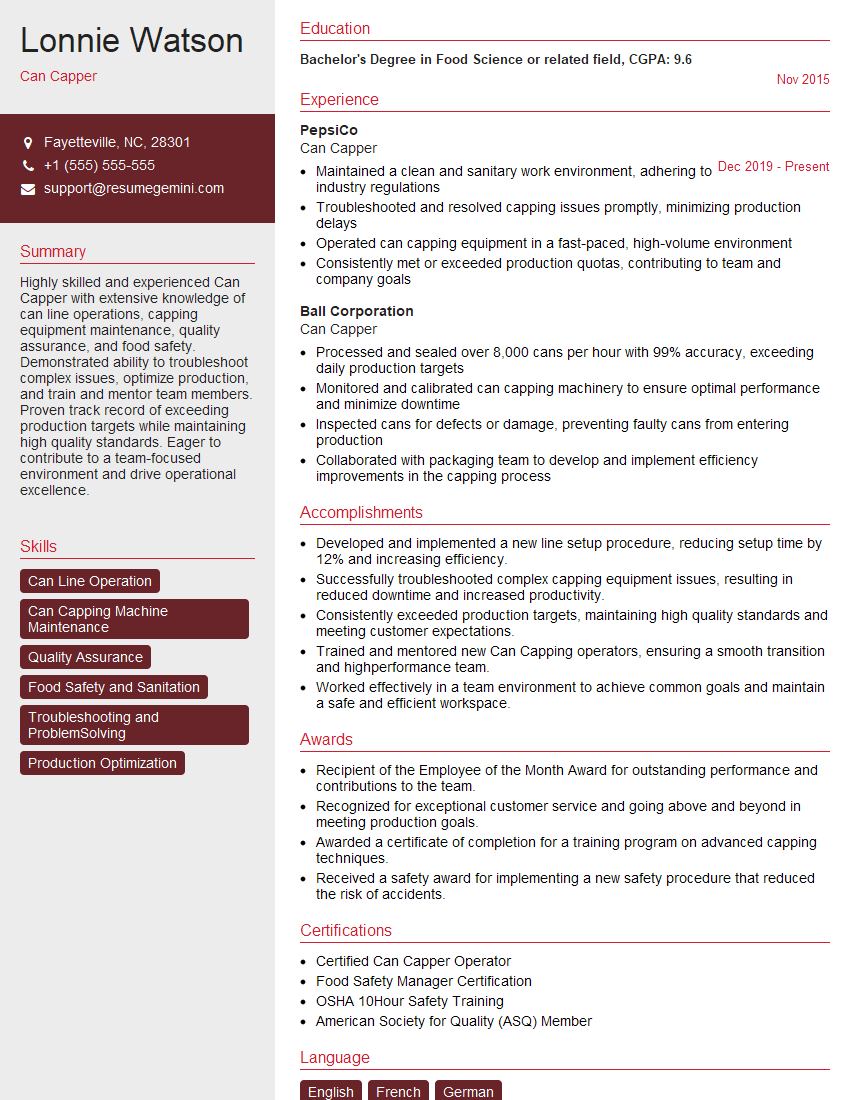

Lonnie Watson

Can Capper

Summary

Highly skilled and experienced Can Capper with extensive knowledge of can line operations, capping equipment maintenance, quality assurance, and food safety. Demonstrated ability to troubleshoot complex issues, optimize production, and train and mentor team members. Proven track record of exceeding production targets while maintaining high quality standards. Eager to contribute to a team-focused environment and drive operational excellence.

Education

Bachelor’s Degree in Food Science or related field

November 2015

Skills

- Can Line Operation

- Can Capping Machine Maintenance

- Quality Assurance

- Food Safety and Sanitation

- Troubleshooting and ProblemSolving

- Production Optimization

Work Experience

Can Capper

- Maintained a clean and sanitary work environment, adhering to industry regulations

- Troubleshooted and resolved capping issues promptly, minimizing production delays

- Operated can capping equipment in a fast-paced, high-volume environment

- Consistently met or exceeded production quotas, contributing to team and company goals

Can Capper

- Processed and sealed over 8,000 cans per hour with 99% accuracy, exceeding daily production targets

- Monitored and calibrated can capping machinery to ensure optimal performance and minimize downtime

- Inspected cans for defects or damage, preventing faulty cans from entering production

- Collaborated with packaging team to develop and implement efficiency improvements in the capping process

Accomplishments

- Developed and implemented a new line setup procedure, reducing setup time by 12% and increasing efficiency.

- Successfully troubleshooted complex capping equipment issues, resulting in reduced downtime and increased productivity.

- Consistently exceeded production targets, maintaining high quality standards and meeting customer expectations.

- Trained and mentored new Can Capping operators, ensuring a smooth transition and highperformance team.

- Worked effectively in a team environment to achieve common goals and maintain a safe and efficient workspace.

Awards

- Recipient of the Employee of the Month Award for outstanding performance and contributions to the team.

- Recognized for exceptional customer service and going above and beyond in meeting production goals.

- Awarded a certificate of completion for a training program on advanced capping techniques.

- Received a safety award for implementing a new safety procedure that reduced the risk of accidents.

Certificates

- Certified Can Capper Operator

- Food Safety Manager Certification

- OSHA 10Hour Safety Training

- American Society for Quality (ASQ) Member

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Can Capper

- Quantify your accomplishments using specific metrics and data whenever possible.

- Highlight your problem-solving abilities and how you’ve resolved complex issues.

- Emphasize your commitment to safety and quality by mentioning relevant certifications or awards.

- Include any experience with lean manufacturing or continuous improvement initiatives.

Essential Experience Highlights for a Strong Can Capper Resume

- Operate and maintain can capping machines, ensuring efficient and safe production lines.

- Implement and follow quality assurance procedures to ensure product meets specifications.

- Identify and resolve production issues, minimizing downtime and maximizing productivity.

- Train and supervise new Can Capping operators, fostering a high-performance team.

- Maintain a clean and organized work area, adhering to food safety and sanitation regulations.

- Collaborate with other departments to optimize production processes and improve overall efficiency.

- Stay up-to-date with industry best practices and technological advancements.

Frequently Asked Questions (FAQ’s) For Can Capper

What is the primary role of a Can Capper?

The primary role of a Can Capper is to operate and maintain can capping machines, ensuring the efficient and safe production of canned goods.

What are the essential skills required for this position?

Essential skills for a Can Capper include can line operation, capping machine maintenance, quality assurance, food safety and sanitation, troubleshooting, and problem-solving.

What type of work environment can I expect as a Can Capper?

As a Can Capper, you can expect to work in a fast-paced production environment, often involving shift work.

What are the career advancement opportunities for a Can Capper?

Career advancement opportunities for a Can Capper may include promotions to supervisory roles, such as Production Supervisor or Quality Assurance Manager.

What are the safety precautions that a Can Capper should follow?

Can Cappers should follow all safety protocols and regulations, including wearing appropriate protective gear, maintaining a clean and organized work area, and adhering to lockout/tagout procedures.

How can I prepare for an interview for a Can Capper position?

To prepare for an interview for a Can Capper position, familiarize yourself with the job description, research the company, and practice answering common interview questions related to your skills and experience.

What certifications are beneficial for a Can Capper?

Beneficial certifications for a Can Capper include food safety certifications, such as ServSafe, HACCP, and SQF, as well as certifications related to specific capping equipment or production processes.