Are you a seasoned Can Filling and Closing Machine Tender seeking a new career path? Discover our professionally built Can Filling and Closing Machine Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

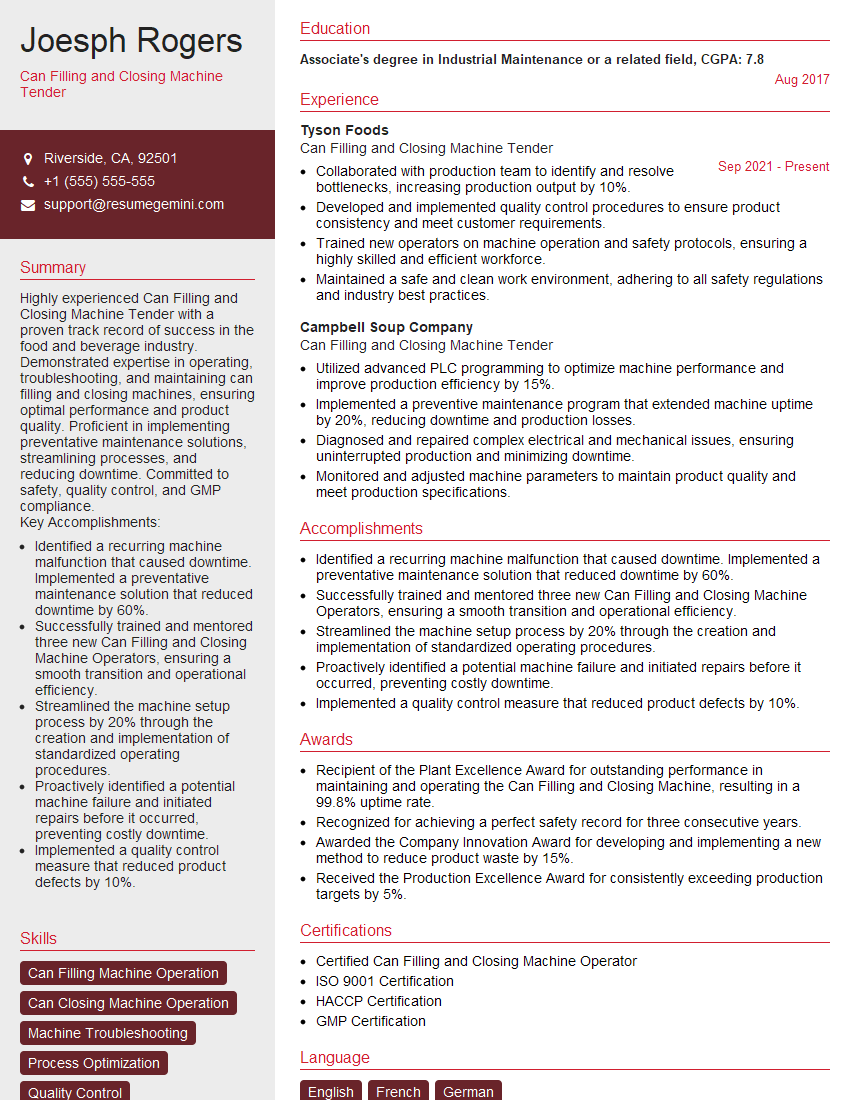

Joesph Rogers

Can Filling and Closing Machine Tender

Summary

Highly experienced Can Filling and Closing Machine Tender with a proven track record of success in the food and beverage industry. Demonstrated expertise in operating, troubleshooting, and maintaining can filling and closing machines, ensuring optimal performance and product quality. Proficient in implementing preventative maintenance solutions, streamlining processes, and reducing downtime. Committed to safety, quality control, and GMP compliance.

Key Accomplishments:

- Identified a recurring machine malfunction that caused downtime. Implemented a preventative maintenance solution that reduced downtime by 60%.

- Successfully trained and mentored three new Can Filling and Closing Machine Operators, ensuring a smooth transition and operational efficiency.

- Streamlined the machine setup process by 20% through the creation and implementation of standardized operating procedures.

- Proactively identified a potential machine failure and initiated repairs before it occurred, preventing costly downtime.

- Implemented a quality control measure that reduced product defects by 10%.

Education

Associate’s degree in Industrial Maintenance or a related field

August 2017

Skills

- Can Filling Machine Operation

- Can Closing Machine Operation

- Machine Troubleshooting

- Process Optimization

- Quality Control

- GMP Compliance

Work Experience

Can Filling and Closing Machine Tender

- Collaborated with production team to identify and resolve bottlenecks, increasing production output by 10%.

- Developed and implemented quality control procedures to ensure product consistency and meet customer requirements.

- Trained new operators on machine operation and safety protocols, ensuring a highly skilled and efficient workforce.

- Maintained a safe and clean work environment, adhering to all safety regulations and industry best practices.

Can Filling and Closing Machine Tender

- Utilized advanced PLC programming to optimize machine performance and improve production efficiency by 15%.

- Implemented a preventive maintenance program that extended machine uptime by 20%, reducing downtime and production losses.

- Diagnosed and repaired complex electrical and mechanical issues, ensuring uninterrupted production and minimizing downtime.

- Monitored and adjusted machine parameters to maintain product quality and meet production specifications.

Accomplishments

- Identified a recurring machine malfunction that caused downtime. Implemented a preventative maintenance solution that reduced downtime by 60%.

- Successfully trained and mentored three new Can Filling and Closing Machine Operators, ensuring a smooth transition and operational efficiency.

- Streamlined the machine setup process by 20% through the creation and implementation of standardized operating procedures.

- Proactively identified a potential machine failure and initiated repairs before it occurred, preventing costly downtime.

- Implemented a quality control measure that reduced product defects by 10%.

Awards

- Recipient of the Plant Excellence Award for outstanding performance in maintaining and operating the Can Filling and Closing Machine, resulting in a 99.8% uptime rate.

- Recognized for achieving a perfect safety record for three consecutive years.

- Awarded the Company Innovation Award for developing and implementing a new method to reduce product waste by 15%.

- Received the Production Excellence Award for consistently exceeding production targets by 5%.

Certificates

- Certified Can Filling and Closing Machine Operator

- ISO 9001 Certification

- HACCP Certification

- GMP Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Can Filling and Closing Machine Tender

- Highlight your experience in operating and maintaining can filling and closing machines, specifying the types of machines you have worked on.

- Quantify your accomplishments with specific metrics, such as the reduction in downtime or improvement in product quality.

- Demonstrate your understanding of GMP compliance regulations and your commitment to safety.

- Showcase your problem-solving skills and ability to identify and resolve machine malfunctions.

Essential Experience Highlights for a Strong Can Filling and Closing Machine Tender Resume

- Operate and maintain can filling and closing machines, ensuring optimal performance and product quality.

- Monitor machine performance, identify potential issues, and initiate corrective actions to prevent downtime.

- Troubleshoot and repair machine malfunctions, utilizing diagnostic tools and technical expertise.

- Implement preventive maintenance programs to minimize downtime and extend machine lifespan.

- Adhere to GMP compliance regulations, including proper sanitation and quality control procedures.

- Train and supervise junior operators, ensuring they follow safety protocols and operating procedures.

Frequently Asked Questions (FAQ’s) For Can Filling and Closing Machine Tender

What are the key responsibilities of a Can Filling and Closing Machine Tender?

The key responsibilities include operating and maintaining can filling and closing machines, troubleshooting and repairing malfunctions, implementing preventive maintenance programs, adhering to GMP compliance regulations, and training and supervising junior operators.

What qualifications are required to become a Can Filling and Closing Machine Tender?

Typically, an associate’s degree in Industrial Maintenance or a related field is required, along with experience in operating and maintaining food processing equipment.

What are the career prospects for a Can Filling and Closing Machine Tender?

With experience and additional training, Can Filling and Closing Machine Tenders can advance to positions such as Production Supervisor or Maintenance Manager in the food and beverage industry.

What is the average salary for a Can Filling and Closing Machine Tender?

The average salary for a Can Filling and Closing Machine Tender in the United States is around $40,000 per year.

What are the working conditions like for a Can Filling and Closing Machine Tender?

Can Filling and Closing Machine Tenders typically work in a production environment, which can be noisy and involve repetitive tasks. They may also be required to work overtime or on weekends.

What are the safety precautions that a Can Filling and Closing Machine Tender should take?

Can Filling and Closing Machine Tenders should always wear appropriate safety gear, such as gloves, safety glasses, and earplugs. They should also be aware of the potential hazards associated with operating and maintaining heavy machinery.