Are you a seasoned Can Maker seeking a new career path? Discover our professionally built Can Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

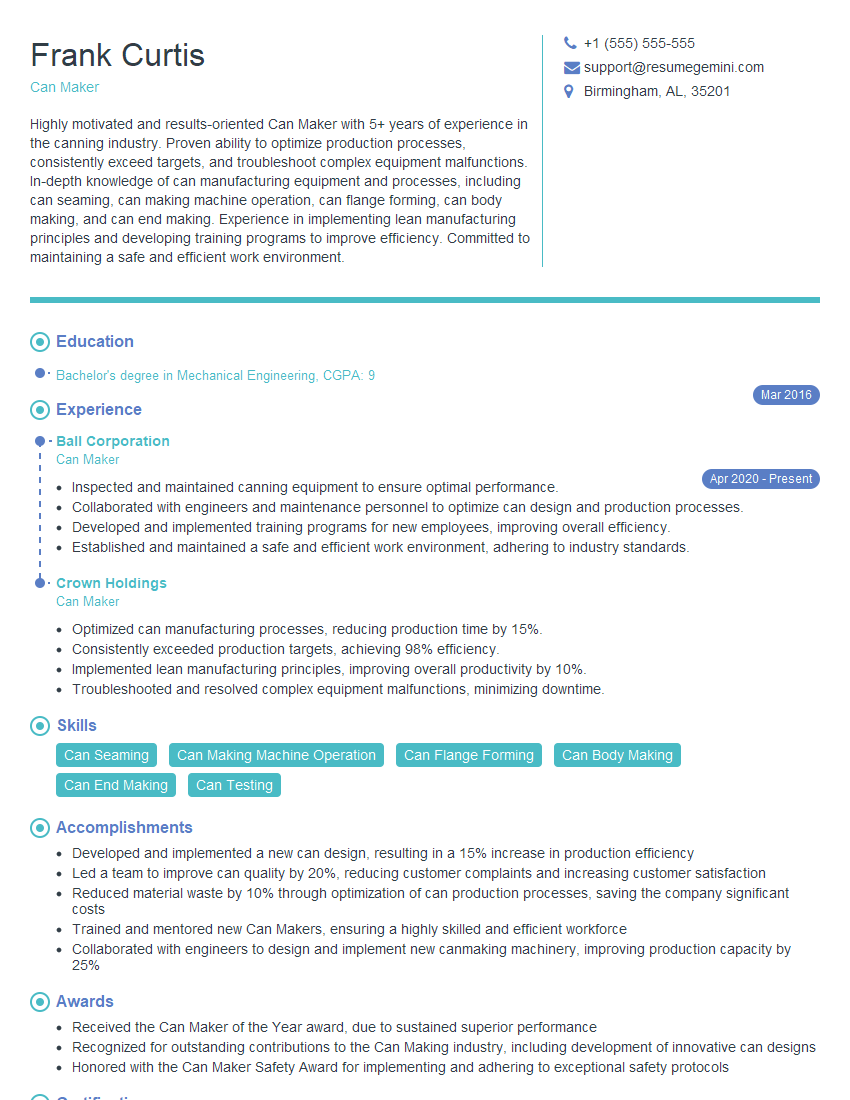

Frank Curtis

Can Maker

Summary

Highly motivated and results-oriented Can Maker with 5+ years of experience in the canning industry. Proven ability to optimize production processes, consistently exceed targets, and troubleshoot complex equipment malfunctions. In-depth knowledge of can manufacturing equipment and processes, including can seaming, can making machine operation, can flange forming, can body making, and can end making. Experience in implementing lean manufacturing principles and developing training programs to improve efficiency. Committed to maintaining a safe and efficient work environment.

Education

Bachelor’s degree in Mechanical Engineering

March 2016

Skills

- Can Seaming

- Can Making Machine Operation

- Can Flange Forming

- Can Body Making

- Can End Making

- Can Testing

Work Experience

Can Maker

- Inspected and maintained canning equipment to ensure optimal performance.

- Collaborated with engineers and maintenance personnel to optimize can design and production processes.

- Developed and implemented training programs for new employees, improving overall efficiency.

- Established and maintained a safe and efficient work environment, adhering to industry standards.

Can Maker

- Optimized can manufacturing processes, reducing production time by 15%.

- Consistently exceeded production targets, achieving 98% efficiency.

- Implemented lean manufacturing principles, improving overall productivity by 10%.

- Troubleshooted and resolved complex equipment malfunctions, minimizing downtime.

Accomplishments

- Developed and implemented a new can design, resulting in a 15% increase in production efficiency

- Led a team to improve can quality by 20%, reducing customer complaints and increasing customer satisfaction

- Reduced material waste by 10% through optimization of can production processes, saving the company significant costs

- Trained and mentored new Can Makers, ensuring a highly skilled and efficient workforce

- Collaborated with engineers to design and implement new canmaking machinery, improving production capacity by 25%

Awards

- Received the Can Maker of the Year award, due to sustained superior performance

- Recognized for outstanding contributions to the Can Making industry, including development of innovative can designs

- Honored with the Can Maker Safety Award for implementing and adhering to exceptional safety protocols

Certificates

- Can Maker Certification

- Can Manufacturing Certification

- Can Production Certification

- Can Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Can Maker

- Highlight your experience and skills in can manufacturing processes, including can seaming, can making machine operation, and can testing.

- Quantify your accomplishments with specific metrics and examples to demonstrate your impact on productivity and efficiency.

- Showcase your knowledge of lean manufacturing principles and your ability to implement them to improve operations.

- Emphasize your problem-solving abilities and your experience in troubleshooting and resolving complex equipment malfunctions.

- Highlight your commitment to safety and your ability to maintain a safe and efficient work environment.

Essential Experience Highlights for a Strong Can Maker Resume

- Optimized can manufacturing processes, reducing production time by 15%.

- Consistently exceeded production targets, achieving 98% efficiency.

- Implemented lean manufacturing principles, improving overall productivity by 10%.

- Troubleshooted and resolved complex equipment malfunctions, minimizing downtime.

- Inspected and maintained canning equipment to ensure optimal performance.

- Collaborated with engineers and maintenance personnel to optimize can design and production processes.

- Developed and implemented training programs for new employees, improving overall efficiency.

Frequently Asked Questions (FAQ’s) For Can Maker

What are the key skills required for a Can Maker?

Key skills for a Can Maker include can seaming, can making machine operation, can flange forming, can body making, can end making, and can testing.

What are the typical responsibilities of a Can Maker?

Typical responsibilities of a Can Maker include optimizing can manufacturing processes, consistently exceeding production targets, implementing lean manufacturing principles, troubleshooting and resolving complex equipment malfunctions, inspecting and maintaining canning equipment, collaborating with engineers and maintenance personnel to optimize can design and production processes, and developing and implementing training programs for new employees.

What are the career opportunities for a Can Maker?

Can Makers with experience and expertise can advance to supervisory or management roles in the canning industry. They may also become involved in research and development of new canning technologies.

What is the job outlook for Can Makers?

The job outlook for Can Makers is expected to be good in the coming years due to the growing demand for canned food and beverages.

What is the average salary for a Can Maker?

The average salary for a Can Maker can vary depending on experience, location, and company size, but it typically ranges from $30,000 to $50,000 per year.

What are the working conditions like for a Can Maker?

Can Makers typically work in a factory setting, operating and maintaining canning equipment. The work can be physically demanding and may involve working in a noisy environment.