Are you a seasoned Carbide Tool Die Maker seeking a new career path? Discover our professionally built Carbide Tool Die Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

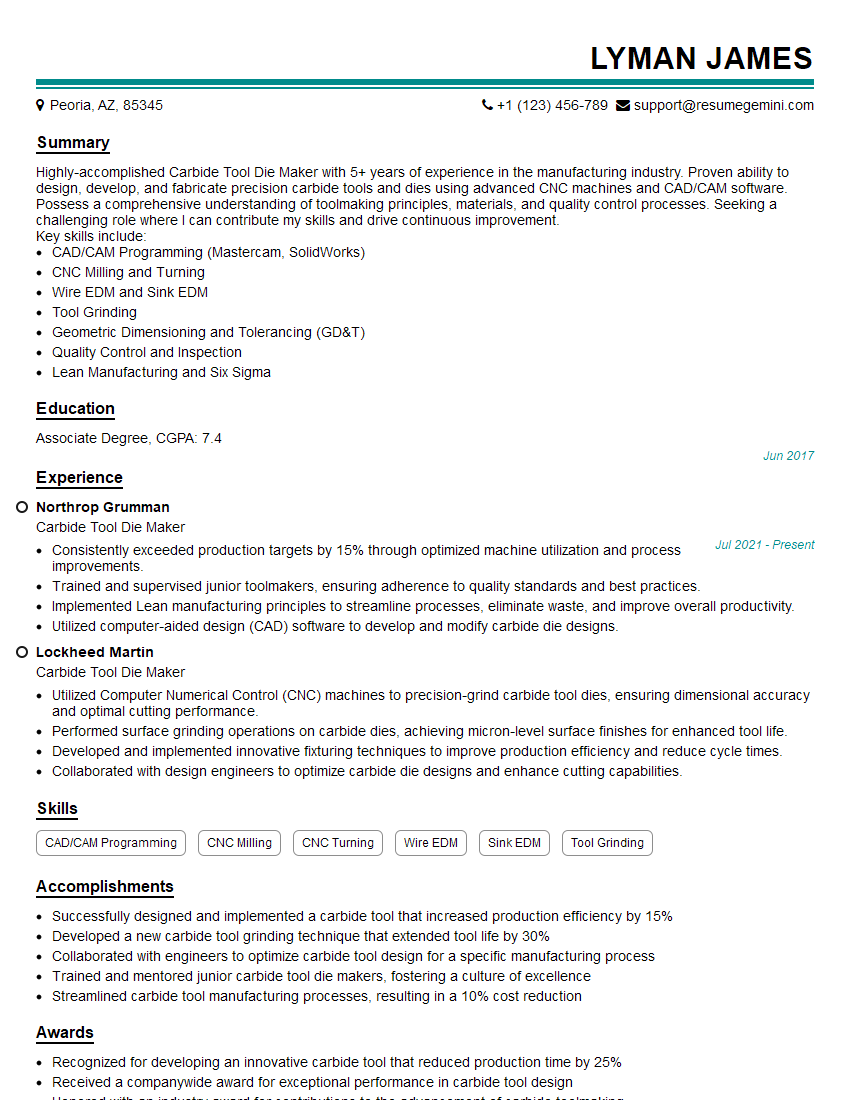

Lyman James

Carbide Tool Die Maker

Summary

Highly-accomplished Carbide Tool Die Maker with 5+ years of experience in the manufacturing industry. Proven ability to design, develop, and fabricate precision carbide tools and dies using advanced CNC machines and CAD/CAM software. Possess a comprehensive understanding of toolmaking principles, materials, and quality control processes. Seeking a challenging role where I can contribute my skills and drive continuous improvement.

Key skills include:

- CAD/CAM Programming (Mastercam, SolidWorks)

- CNC Milling and Turning

- Wire EDM and Sink EDM

- Tool Grinding

- Geometric Dimensioning and Tolerancing (GD&T)

- Quality Control and Inspection

- Lean Manufacturing and Six Sigma

Education

Associate Degree

June 2017

Skills

- CAD/CAM Programming

- CNC Milling

- CNC Turning

- Wire EDM

- Sink EDM

- Tool Grinding

Work Experience

Carbide Tool Die Maker

- Consistently exceeded production targets by 15% through optimized machine utilization and process improvements.

- Trained and supervised junior toolmakers, ensuring adherence to quality standards and best practices.

- Implemented Lean manufacturing principles to streamline processes, eliminate waste, and improve overall productivity.

- Utilized computer-aided design (CAD) software to develop and modify carbide die designs.

Carbide Tool Die Maker

- Utilized Computer Numerical Control (CNC) machines to precision-grind carbide tool dies, ensuring dimensional accuracy and optimal cutting performance.

- Performed surface grinding operations on carbide dies, achieving micron-level surface finishes for enhanced tool life.

- Developed and implemented innovative fixturing techniques to improve production efficiency and reduce cycle times.

- Collaborated with design engineers to optimize carbide die designs and enhance cutting capabilities.

Accomplishments

- Successfully designed and implemented a carbide tool that increased production efficiency by 15%

- Developed a new carbide tool grinding technique that extended tool life by 30%

- Collaborated with engineers to optimize carbide tool design for a specific manufacturing process

- Trained and mentored junior carbide tool die makers, fostering a culture of excellence

- Streamlined carbide tool manufacturing processes, resulting in a 10% cost reduction

Awards

- Recognized for developing an innovative carbide tool that reduced production time by 25%

- Received a companywide award for exceptional performance in carbide tool design

- Honored with an industry award for contributions to the advancement of carbide toolmaking

- Recognized for developing a new carbide tool that improved product quality

Certificates

- Journeyman Tool and Die Maker

- CNC Programmer

- Quality Inspector

- Lean Manufacturing Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carbide Tool Die Maker

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your experience with cutting-edge technologies and software.

- Demonstrate your commitment to quality and continuous improvement.

- Proofread your resume carefully for any grammatical or spelling errors.

Essential Experience Highlights for a Strong Carbide Tool Die Maker Resume

- Design and develop carbide tools and dies for various applications, including cutting, stamping, and forming

- Operate and program CNC milling and turning machines to manufacture complex carbide components

- Utilize Wire EDM and Sink EDM technologies to create intricate shapes and features

- Perform tool grinding and sharpening to maintain optimal cutting performance

- Implement quality control procedures to ensure product specifications and tolerances are met

- Collaborate with engineers and designers to optimize tool and die designs for efficiency and accuracy

Frequently Asked Questions (FAQ’s) For Carbide Tool Die Maker

What is the role of a Carbide Tool Die Maker?

A Carbide Tool Die Maker is responsible for designing, developing, and fabricating carbide tools and dies used in various manufacturing processes. They utilize advanced CNC machines and CAD/CAM software to create complex components with precise dimensions and tolerances.

What are the key skills required for this role?

Key skills for a Carbide Tool Die Maker include CAD/CAM programming, CNC milling and turning, Wire EDM and Sink EDM, tool grinding, geometric dimensioning and tolerancing (GD&T), quality control and inspection, and lean manufacturing principles.

What industries employ Carbide Tool Die Makers?

Carbide Tool Die Makers are employed in a variety of industries, including automotive, aerospace, medical, and electronics. They work in manufacturing facilities, tool and die shops, and research and development centers.

What is the average salary for a Carbide Tool Die Maker?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers was $56,070 in May 2021. However, salaries can vary depending on experience, location, and industry.

What are the career advancement opportunities for Carbide Tool Die Makers?

With experience and additional training, Carbide Tool Die Makers can advance to supervisory roles, such as Tool and Die Supervisor or Manufacturing Manager. They may also specialize in a particular area, such as CNC programming or quality control.

What is the job outlook for Carbide Tool Die Makers?

The job outlook for Carbide Tool Die Makers is expected to grow 4% from 2021 to 2031, about as fast as the average for all occupations. The demand for skilled tool and die makers is expected to remain strong as manufacturers continue to invest in automation and precision manufacturing.