Are you a seasoned Carbon Blocks Press Operator seeking a new career path? Discover our professionally built Carbon Blocks Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

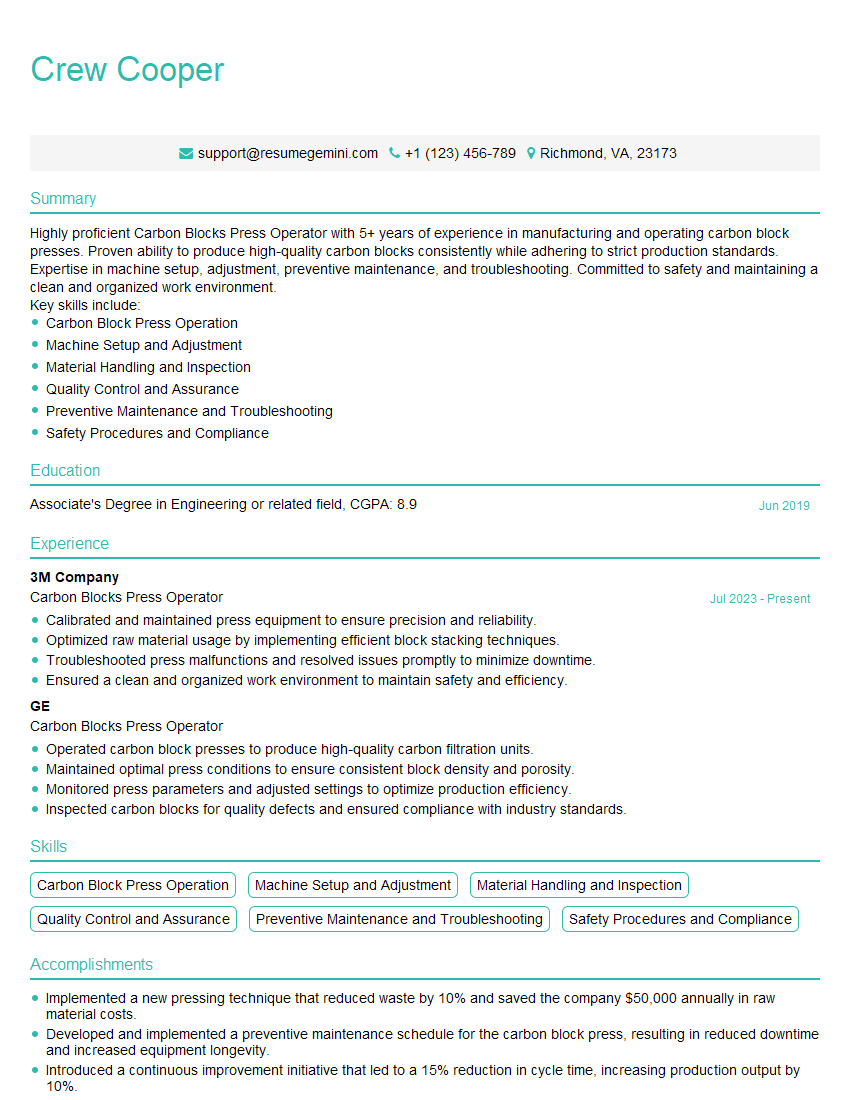

Crew Cooper

Carbon Blocks Press Operator

Summary

Highly proficient Carbon Blocks Press Operator with 5+ years of experience in manufacturing and operating carbon block presses. Proven ability to produce high-quality carbon blocks consistently while adhering to strict production standards. Expertise in machine setup, adjustment, preventive maintenance, and troubleshooting. Committed to safety and maintaining a clean and organized work environment.

Key skills include:

- Carbon Block Press Operation

- Machine Setup and Adjustment

- Material Handling and Inspection

- Quality Control and Assurance

- Preventive Maintenance and Troubleshooting

- Safety Procedures and Compliance

Education

Associate’s Degree in Engineering or related field

June 2019

Skills

- Carbon Block Press Operation

- Machine Setup and Adjustment

- Material Handling and Inspection

- Quality Control and Assurance

- Preventive Maintenance and Troubleshooting

- Safety Procedures and Compliance

Work Experience

Carbon Blocks Press Operator

- Calibrated and maintained press equipment to ensure precision and reliability.

- Optimized raw material usage by implementing efficient block stacking techniques.

- Troubleshooted press malfunctions and resolved issues promptly to minimize downtime.

- Ensured a clean and organized work environment to maintain safety and efficiency.

Carbon Blocks Press Operator

- Operated carbon block presses to produce high-quality carbon filtration units.

- Maintained optimal press conditions to ensure consistent block density and porosity.

- Monitored press parameters and adjusted settings to optimize production efficiency.

- Inspected carbon blocks for quality defects and ensured compliance with industry standards.

Accomplishments

- Implemented a new pressing technique that reduced waste by 10% and saved the company $50,000 annually in raw material costs.

- Developed and implemented a preventive maintenance schedule for the carbon block press, resulting in reduced downtime and increased equipment longevity.

- Introduced a continuous improvement initiative that led to a 15% reduction in cycle time, increasing production output by 10%.

- Collaborated with design engineers to optimize the press settings, resulting in a 7% increase in product strength and decreased material defects.

- Trained and mentored new operators, ensuring they met performance standards and maintained high levels of safety.

Awards

- Received the Manufacturing Excellence Award for outstanding performance in carbon block pressing operations, leading to a 5% increase in production efficiency.

- Recognized as Employee of the Month for consistently exceeding production targets and achieving the highest quality standards.

- Awarded the Safety Excellence Award for maintaining a spotless safety record and actively promoting a safe working environment.

- Received the Lean Manufacturing Certification for implementing lean principles and improving process efficiency.

Certificates

- OSHA Safety Certification

- National Institute for Metalworking Skills (NIMS) Certification

- American Welding Society (AWS) Certification

- ISO 9001 Quality Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carbon Blocks Press Operator

- Highlight your technical skills and experience in carbon block press operation and maintenance.

- Showcase your understanding of quality control procedures and your commitment to producing high-quality products.

- Emphasize your ability to work independently and as part of a team in a fast-paced manufacturing environment.

- Quantify your accomplishments whenever possible to demonstrate your impact on production efficiency or quality.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Carbon Blocks Press Operator Resume

- Operate carbon block press to produce high-quality carbon blocks according to specifications.

- Set up and adjust press machines to ensure optimal performance and block quality.

- Handle and inspect raw materials and finished blocks to maintain quality standards.

- Conduct quality control checks and assure compliance with quality control protocols.

- Perform preventive maintenance and troubleshoot press machines to minimize downtime.

- Follow safety procedures and maintain a clean and organized work environment.

- Communicate effectively with supervisors, team members, and quality control personnel.

Frequently Asked Questions (FAQ’s) For Carbon Blocks Press Operator

What is the primary role of a Carbon Blocks Press Operator?

The primary role of a Carbon Blocks Press Operator is to operate carbon block presses to produce high-quality carbon blocks according to specifications.

What skills are required to be a successful Carbon Blocks Press Operator?

To be a successful Carbon Blocks Press Operator, you will need a strong understanding of carbon block press operation, machine setup and adjustment, material handling and inspection, quality control and assurance, preventive maintenance and troubleshooting, and safety procedures and compliance.

What are the key responsibilities of a Carbon Blocks Press Operator?

The key responsibilities of a Carbon Blocks Press Operator include operating carbon block press to produce high-quality carbon blocks, setting up and adjusting press machines, handling and inspecting raw materials and finished blocks, conducting quality control checks, performing preventive maintenance and troubleshooting, following safety procedures, and communicating effectively with team members.

What are the career prospects for Carbon Blocks Press Operators?

Carbon Blocks Press Operators can advance their careers by becoming supervisors, quality control inspectors, or production managers. With additional training or education, they may also pursue roles in engineering or management.

What is the work environment of a Carbon Blocks Press Operator like?

Carbon Blocks Press Operators typically work in manufacturing facilities. They may be exposed to noise, dust, and heat. They must be able to work independently and as part of a team, and they must be able to follow safety procedures.

What is the salary range for Carbon Blocks Press Operators?

The salary range for Carbon Blocks Press Operators varies depending on experience, location, and company size. According to Salary.com, the average salary for Carbon Blocks Press Operators in the United States is $45,000 per year.

What are the benefits of working as a Carbon Blocks Press Operator?

Benefits of working as a Carbon Blocks Press Operator include job security, opportunities for advancement, and a competitive salary and benefits package.